The Dangers of Single Sourcing in Your Supply Chain

Resilinc

APRIL 17, 2024

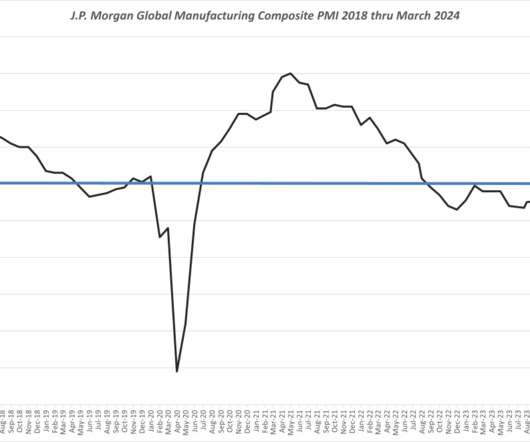

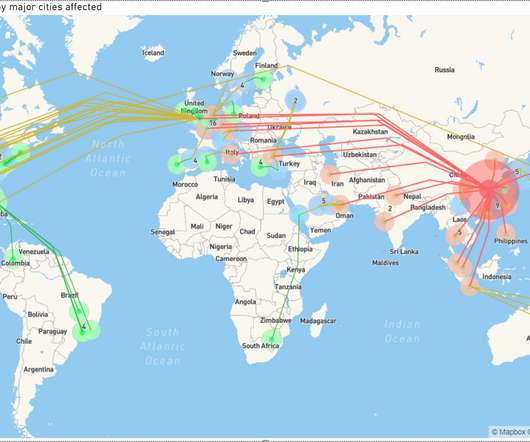

Avoid the pitfalls of single sourcing and learn strategies to build a more resilient supply chain. Yet, within the pursuit of efficiency lies a lurking peril: single sourcing. The pandemic was a wake-up call to the dangers of single sourcing. What is single sourcing and sole sourcing?

Let's personalize your content