The Role of Blockchain in SCM, with Examples

SCMDOJO

OCTOBER 14, 2023

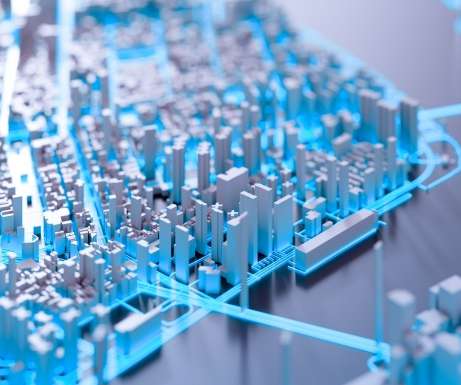

What is a supply chain management system (SCM)? When talking about SCM, we can elaborate it as integrating all dependent business activities, including resources and actors, to smoothen the workflow. It has made visible changes in the SCM systems. For strict security purposes, authorized blockchains are preferred in SCM systems.

Let's personalize your content