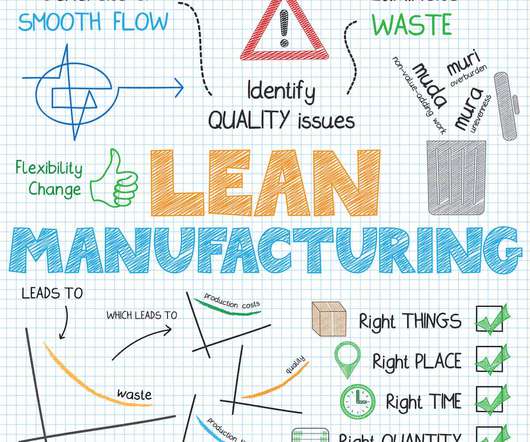

How Prominent Video Game Technology is Changing Industrial Training and Manufacturing

Supply Chain Brain

SEPTEMBER 12, 2023

Managers of manufacturing and training operations will need to see a faster ROI if this technology hopes to become a staple of supply chains.

Let's personalize your content