Supply Chain KPIs & Metrics: Our Top 24 for Manufacturers

Silvon Software

JULY 22, 2022

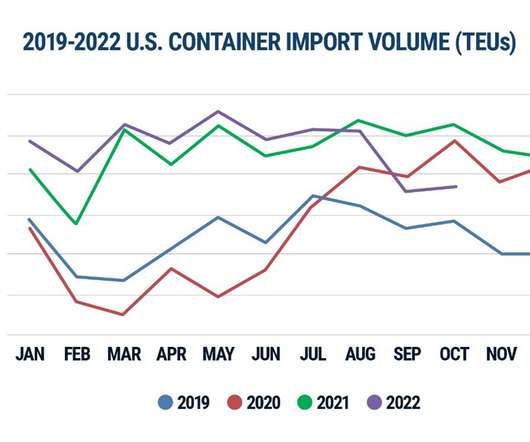

Fortunately, applying metrics to multi-source operational information that’s stored and managed in a data hubs greatly minimizes these issues. Supply chain metrics provide the intelligence needed to make better projections and more informed choices in such a market. Our Top 24 Supply Chain KPIs & Metrics.

Let's personalize your content