Supply Chain KPIs & Metrics: Our Top 24 for Manufacturers

Silvon Software

JULY 22, 2022

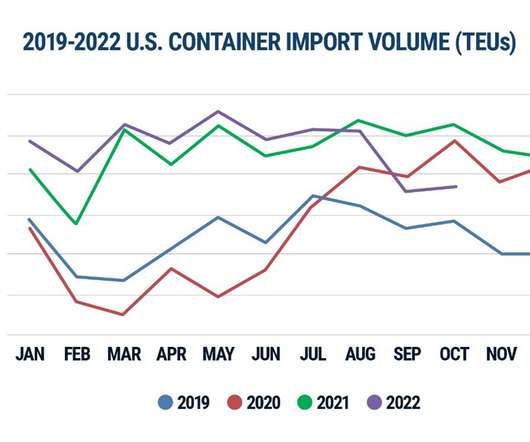

For one thing, today’s operational processes have become more complicated due to the ever-growing number of sources, platforms and touchpoints that must now be analyzed in order to drive actionable insights from them. Supply chain metrics provide the intelligence needed to make better projections and more informed choices in such a market.

Let's personalize your content