AI in the Retail Industry: Benefits, Case Studies & Examples

ThroughPut

MARCH 27, 2024

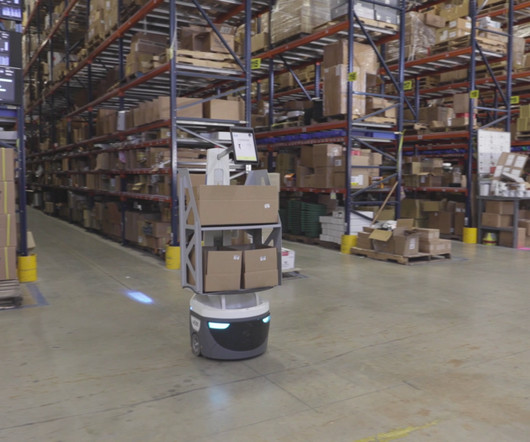

The Evolution of Retail Supply Chain & Logistics: A Pre-AI Overview In the pre-AI era, the retail sector was markedly different, especially since the traditional supply chain and logistics models were largely driven by manual labor. How is AI Revolutionizing Retail Supply Chains?

Let's personalize your content