Unlocking Success: Why Strategic Sourcing Is Important for Your Company

Precoro

DECEMBER 11, 2023

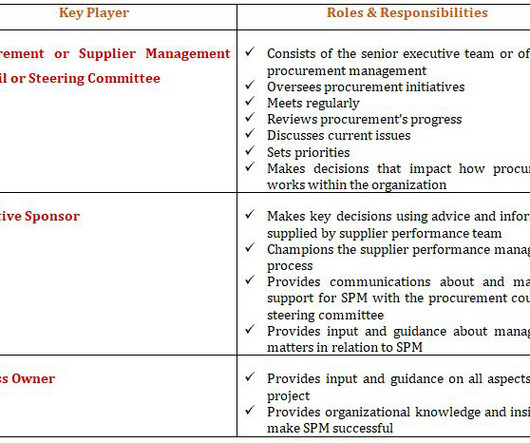

To enhance their competitive edge, companies across industries are adopting a key tactic: strategic sourcing. Strategic sourcing is a holistic approach to supply chain management that includes tactics for optimizing the total cost of ownership, improving supplier relationships, and ensuring long-term value creation.

Let's personalize your content