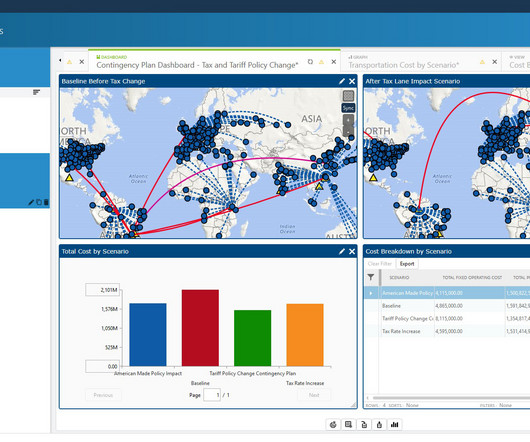

Scenario Modeling Is Now Crucial for Supply Chain Network Design

AIMMS

JUNE 16, 2020

How are companies leveraging scenario modeling for network design and optimization ? The good news is many of the survey’s respondents recognize the potential of more advanced optimization solutions. In the context of disruptions like COVID-19, scenario modeling can make considerable difference – Tweet this.

Let's personalize your content