How business intelligence can boost customer centricity

SYSPRO Smarter ERP

JUNE 14, 2022

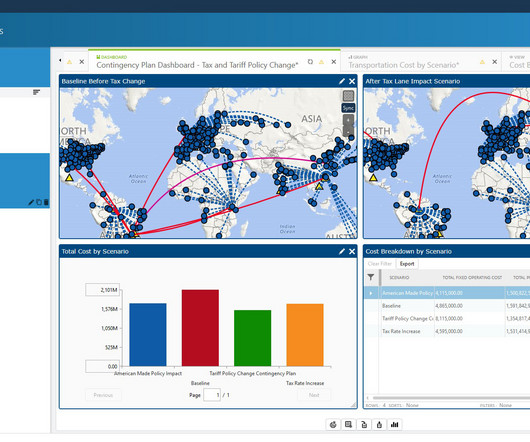

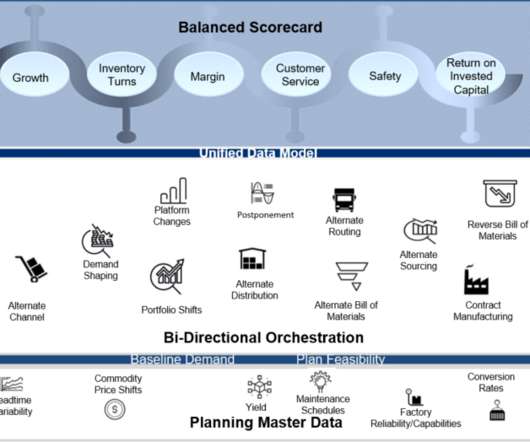

The pandemic also opened the door for new competitors, an increased need for predictive data, and a need for new customer-centric business intelligence models. The Ukraine war also has a large impact on car manufacturers in Europe, highlight the risk associated with the current global supply chain.

Let's personalize your content