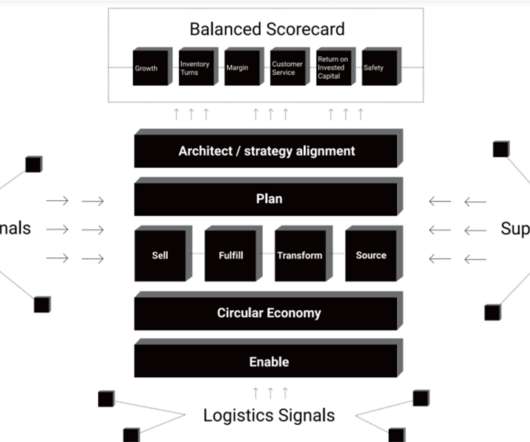

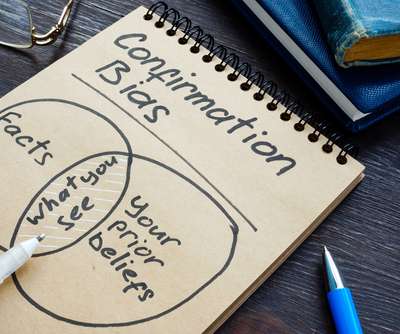

Why Organizational Alignment is Critical to the Supply Chain Response

Supply Chain Shaman

MAY 15, 2023

Let me explain, if you fill out one of my surveys on LinkedIn, I share the research results in front of the paywall (I believe that supply chain research should be readily available and not locked behind a paywall.) (If Most see their supply chain as fixed and insular.

Let's personalize your content