Risk Management Can Be a Competitive Advantage, Part One

Enterra Insights

AUGUST 24, 2023

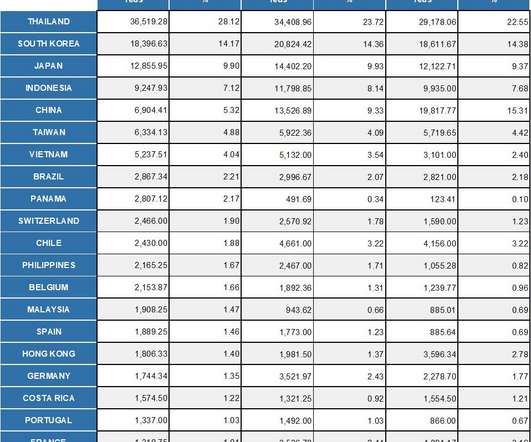

The Mint staff adds, “Supply chain risk is a modern day reality and can emanate from a variety of sources, ranging from natural disasters to government policies and a host of other unforeseen events.”[2] In other words, good risk management can provide a significant competitive advantage for businesses.

Let's personalize your content