Supply Chain Resilience. Really?

Supply Chain Shaman

DECEMBER 7, 2023

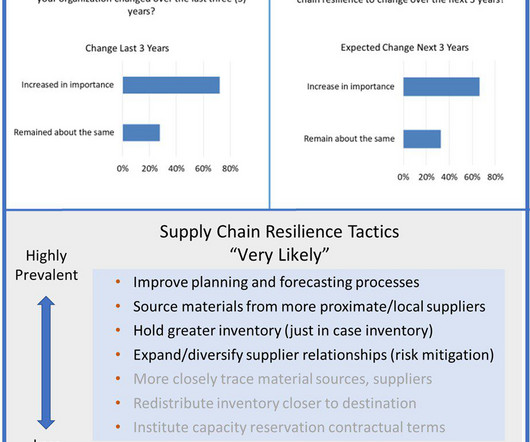

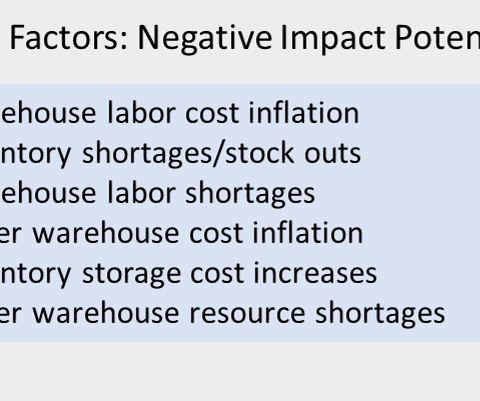

Today, I speak at the North American Manufacturing Association, Manufacturing Leadership Conference, in Nashville on the use of data to improve supply chain resilience. Background The Council of Supply Chain Resilience met for the first time this month. What is supply chain resilience? The reason?

Let's personalize your content