Pricing Optimization at Delly’s: A Case Study in Successful AI Enablement

Talking Logistics

SEPTEMBER 27, 2023

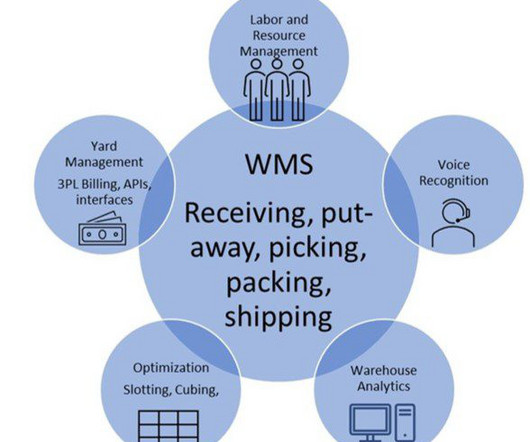

This includes implementing Enterprise Resource Planning (ERP), Customer Relationship Management (CRM), Demand Planning, Inventory Management, Transportation Management, and Warehouse Management applications. After capturing many of.

Let's personalize your content