This post has already been read 7513 times!

In my first post I discussed the power of a modern planning system that combines planning and execution, and more importantly, enables Optimized Execution.

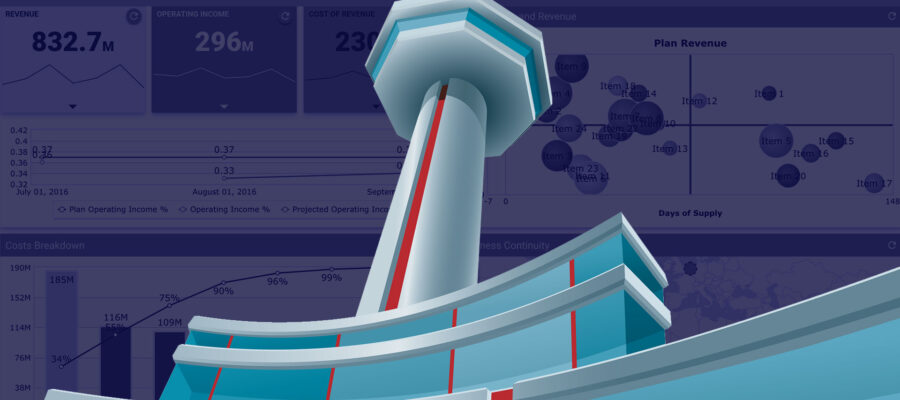

A Supply Chain Planning Control Tower built on this system, means it can solve for all problems or opportunities across the full-time horizon, years down to seconds.

Capabilities include network-wide visibility, collaboration, AI/prescriptive analytics, and, what’s really fundamental to making it work, is a common data model that spans the entire supply chain.

Now you have a Supply Chain Planning Control Tower that is able to represent the full network consistently, because you have a common data model across all trading partners. The system can present this data as a real-time, single version of the truth, across all roles and perspectives. (This does require a robust and flexible permission framework, where permissions can be given based on organization and role.)

Let me repeat that, because vendors have muddied the waters by talking about “single networks” for years, when in reality, they’re providing a collection of separate systems, separate databases, and separate data models. These (usually acquired) systems are all designed to do different things, yet they are plumbed together to try to make a full suite. This creates implementation nightmares, data synchronization issues, and data conflicts.

"Vendors have misleadingly called their solutions 'single networks,' when in fact they are separate systems, databases, and data models, plumbed together, creating implementation and data synchronization nightmares." Click To TweetThe new era of planning and execution runs on one system, using one integrated data model for your entire network, and served up in real time, at your fingertips, through the control tower.

These Control Towers can be configured by role, and can roll up and aggregate data to the executive level. The single data model enables you to roll up to attributes, families, categories, etc., for planning purposes; and to roll down to items, sites, and lanes, for execution purposes.

Some planning solutions fake this, by displaying order information on a planning workbench, but without an integrated data model, there can be no type of workflow enabled between planning and transactions. This is why the planning married to execution model expands as we approach execution. It is the data available in a digitized supply chain network that expands as we move from months toward seconds. The real question is: Are you are capable of driving value through the data expansion including all the IoT process variables?

A platform with planning married to execution via a single data model, is the only way to have everyone and everything working from a single version of the truth.

"A platform with planning married to execution via a single data model, is the only way to have everyone and everything working from a single version of the truth, and to enable seamless planning and execution." -Joe Bellini Click To TweetThis is very different to having two separate systems and data models, designed to do different things, then wired together. Decision making is contextual, based on the current state of the demand/supply match in a few hours or in a few months. Making decisions quickly so we don’t continue making the wrong volume/mix upstream in the network is critical regardless of time-frame especially given the lead times and capacity constraints involved.

The Benefits of Modern Supply Chain Planning & Execution Platform

This planning and execution platform doesn’t require integration between various tools on the platform, they were designed from the start to work as one, from the same data. This is a major benefit, because the AI decision making capabilities sit on top of a single data model. This means it can now look at data across all portions of the supply chain simultaneously, and in real time, instead of having to look at it silo by silo. The system can now concurrently optimize for service levels, inventory, and logistics, based on this single version of real-time data in both planning and execution rather than just from a planning perspective.

The modern planning platform takes into account the reality of today’s business. It must be designed to work with existing systems and data sources, for a number of reasons, but chiefly, because these systems often represent significant investments, still provide lots of value, and because a “rip and replace” approach is impractical and extremely risky.

The modern planning platform embraces legacy systems, and enables you to run your current systems in parallel with the planning platform, which serves as a system of engagement.”

Joe Bellini

Thus, the modern planning platform is architected to embrace external and legacy systems, enabling a dual platform strategy, one where you can continue to run your systems as normal, while the planning platform runs as a system of engagement, in parallel, unifying and coordinating your systems of record.

A “tunable system of control” is vital here. It should be able to easily delegate processes or steps to either the network platform, or an external system, while coordinating the overall, end-to-end workflow.

The Planning Control Tower can be deployed as a standalone capability enabling a system of engagement across your planners, schedulers, and expeditors. In similar fashion IBP/S&OP, Advanced Planning, or Execution services can all be deployed as best in class process flows driving network benefits across the trading partner ecosystem.

Planning Control Tower Enabled with Execution

Planning is not an end in itself. Planning exists to deliver on the highest customer service levels at the least landed cost by first planning demand and then moving supply to demand to satisfy the consumer. That requires a coordinated collaboration across the entire network. A modern planning platform connects all trading partners via a single platform, running on a single data model, and gives them the tools delivered through a network-based control tower, to coordinate plans, and collaborate all the way through execution and final delivery.

A single platform that can enable planning, across all time horizons, through to execution is the key. And most importantly with today’s highly variable and uncertain markets, leveraging an Optimized Execution process capability to enable autonomous execution across a robust digitized supply chain network data set solving for problems and adjusting plans to ensure monthly and quarterly business objectives are achieved.

You might also like…

- What Constitutes a True Network?

- Real-World Supply Chain Robotics

- Supply Chain Trends to Watch

- Fielding Software to Defense: A Journey of Ineffectiveness, Inefficiency, and Frustration

- My Biggest Takeaways from NRF 2024 – Retail’s Big Show

- 8 Actionable Supply Chain Trends for 2023 - January 19, 2023

- Constraint-Based Supply Planning & Execution - November 21, 2022

- Supply Chain Planning Control Tower - September 29, 2022