It is arguably true that supplier performance management is considered a business practice for measuring, analyzing, and managing supplier performance to reduce cost, and risk and also drive continuous improvement. Therefore, the ultimate goal is to identify potential problems and their causes so that they can be resolved early for the benefit of all.

Why Supplier Performance Management is crucial?

Managing and optimizing a supplier’s performance is as essential as it is difficult. Price isn’t everything. Your supplier may charge you an agreed-upon price, but if the service is unmarked or the merchandise is of poor quality, you won’t be able to meet your savings goals.

Supplier performance management provides detailed information about the risks your suppliers may have, so you can take action to reduce or eliminate risks in your supply chain.

Making Sure Suppliers Are Good

How is it possible? Most companies rely on on-time delivery, price reduction, and quality service from suppliers to make more profit. Therefore, the success of supplier performance management directly affects the quality of the entire supply chain. For this reason, it is important to establish an effective mechanism to improve it, accelerate its improvement, and ensure the quality of the service and/or product.

The three terms supplier evaluation, supplier approval, and supplier evaluation are sometimes confused. Each of these three terms is defined as follows:

- Supplier Evaluation – Assess a potential supplier’s ability to control quality, delivery, quantity, price, and any other factors included in the contract.

- Supplier Approval – Places the company on the approved supplier list following the supplier evaluation process.

- Supplier Ratings – An indicator of how suppliers are performing.

Each term has one or more synonyms: Supplier or vendor evaluation is synonymous with supplier appraisal; supplier certification with supplier approval and supplier performance with supplier rating. These three activities can be viewed as aspects of a continuous process. Supplier appraisal leads to supplier approval followed by supplier rating.

Supplier rating may lead either to re-approval or reappraisal and removal from the list of approved suppliers.

Current State of Supplier Performance Management

Nowadays, the interest in improving supplier performance management methods has increased due to the increase in global sourcing and that of the global economy in particular (Gordon Sherry R, 2008).

If we try to interview supply chain managers or supplier quality managers and ask them how many of them measure supplier performance, around 50-75% will answer with a YES. However, if we ask them how many are satisfied with their systems or their approaches to doing so, very few, and often no one will tell us. Supplier performance management is fraught with challenges and difficulties for several reasons. The biggest challenge is that simply offering metrics, even those that appear to be the “right” metrics, usually doesn’t produce any results. The questions that are most often asked are:

- What metrics should I use?

- What metrics do others (in my industry) use?

- My boss says that I need to get a scorecard in place in the next six months. Where do I begin?

Standalone metrics of metrics borrowed from other companies have a low chance of success because :

- They are not part of an overall supply management program.

- They do not relate to any overall company procurement goals and objectives.

- They are often data collection exercises with no teeth enforcing compliance and no actions resulting from them

The Basics of How To Develop a Supplier Performance Management Project Team – Structure & Stages

SPM (Supplier Performance Management) Stages

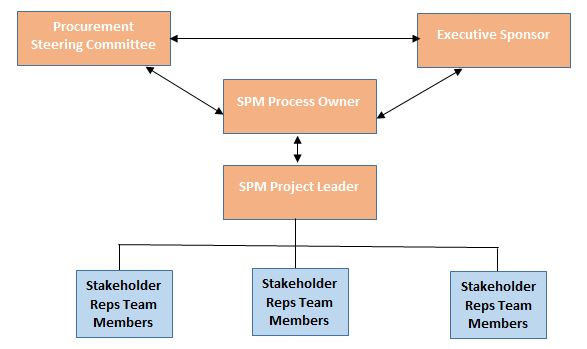

An SPM (Supplier Performance Management) project involves change management. It’s crucial to have a clear plan and support from senior management. Internal and external stakeholders should be represented, with ongoing communication. This requires creating a team and defining its structure. Depending on the size of your business and how organized you are, there are a variety of approaches that can be successful (Gordon Sherry R, 2008).

Figure 1 shows a sample proposed SPM project structure for a transportation services company.

Figure 1: SPM Project Stages (Gordon Sherry R, 2008)

Procurement Steering Committee and Executive Sponsor:

This organization has created a Procurement Steering Committee with management participation to leverage procurement as a tool to improve business performance. Some companies may have a board of directors. Others will have a purchasing or supplier management board at the senior management level.

To ensure the success of an SPM project, there must be an Executive Sponsor. This person can sit on the procurement council or the steering committee. Executive sponsor responsibilities may include the following:

- Championing the SPM process with senior management

- Helping obtain and then maintaining the commitment and financial support of senior management

- Ensuring the link and alignment between the SPM project and corporate strategies, goals, and objectives

- Providing communications about and maintaining support for SPM with the procurement council or steering committee

- Providing input and guidance about corporate internal matters about SPM

SPM Process Owner:

Ideally, SPM should be more than just a project. It should be about a process and there should be a Process Owner for supplier performance management. We are talking about a key business process that impacts multiple functions beyond just organizing purchasing or quality. In a cross-functional process, one person must be accountable for the health and success of that process and responsible for coordinating the various functions and work activities at all levels of a process. The process owner’s responsibilities would include the following (Gordon Sherry R, 2008) :

- Providing input and guidance on the project

- Providing organizational knowledge and insights to make SPM successful

- Developing an understanding of and advising on best practices in SPM

SPM Project Leader:

The project manager (SPM Project Leader) steers and directs the SPM project. This person should be responsible for some of the main tasks and missions presented as follows :

- Working to select and manage the SPM project team

- Guiding procurement and other impacted functions through the SPM process

- Planning and development of all project deliverables

- Defining components and tools of the SPM process as well as the process itself

- Managing the day-to-day activities of the project

The SPM project team is responsible for performing detailed work in developing the SPM system. This team should include representatives (Stakeholder Representative Team Members) from the organization who are impacted by supplier performance or actively work with suppliers. Some of them embody an advisory role, representing the stakeholders of the process throughout the organization. Others do the detailed work; develop apply and practice all aspects of the supplier performance management process, from supplier performance expectations, process design and development, and implementation to monitoring and continuous process improvement.

As vendors are important stakeholders in the development and deployment of SPM, vendors should not be represented on this team by the participation of selected vendor representatives.

SPM (Supplier Performance Management) Structure

To have a successful supplier performance management program, two critical success factors should be considered: management support and having a clearly defined and robust evaluation process in place (Gordon Sherry R, 2008). One of the reasons why supplier performance programs do not have such an impact is that they are developed and deployed in a vacuum that despite aligning metrics with overall supply management and organizational goals, supplier evaluation cannot operate on its own. In a concretely robust program, you may need input and therefore cooperation from various stakeholders in your organization and the supplier organization.

Because of cross-functional recommendations and critical input from others, the evaluation process should be clearly defined and documented. After gaining management support for vendor assessment, there should ideally be an executive sponsor for the vendor assessment initiative who can ensure that the appropriate resources are engaged and serve as a communication link with the senior management.

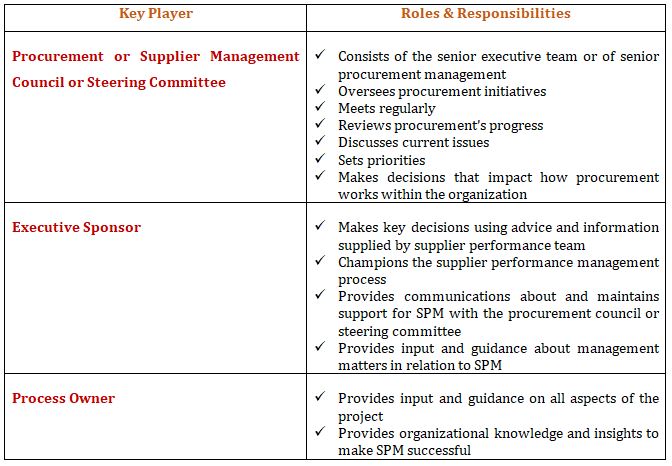

Figure 2 summarizes how a supplier performance initiative can be organized.

Three key elements are suggested. The first is the creation of a procurement or supplier management board or steering committee at a higher level that meets regularly to set priorities, oversee initiatives, review progress, and make policy decisions about strategy. and procurement and supply management operations. Supplier performance management is usually only one of the areas in which this board or steering committee provides leadership and decision-making.

Figure 2: SPM Project Roles & Responsibilities (Gordon Sherry R, 2008)

Supplier Performance Assessment – What are the criteria?

Supplier evaluation is situational. What to evaluate should be related to the requirements of the particular buyer (Knowledge Works, CIPS). However, all assessments will assess providers of aspects such as financing, production capacity and facilities, human resources, quality, performance, environmental and ethical considerations, and IT.

Finance

The financial assessment should reduce, but not eliminate, the risk of doing business with a company whose financial viability is uncertain. It does, however, provide information for making informed decisions when sourcing suppliers or evaluating bids. The recommended checks are listed as follows:

- The assessed turnover of the enterprise over three years.

- The profitability and the relationship between gross and net profits of the enterprise over three years.

- The value of capital assets and return on capital assets and return on capital employed.

- Other Elements

Production Capacity

Capacity is a difficult concept to grasp as it has to relate to the extent to which a facility is used, e.g. this could be the policy of using production capacity five days a week, one shift a day, or producing a maximum of 2,000 units per month. Factory capacity can normally be increased by overtime, adding new facilities and suppliers’ attention should be paid to: the maximum production capacity in a normal working period, the extent to which the capacity is currently over or under-committed, a full order book may rise doubts about their ability to take on other tasks, etc.

Production Facilities

The assessment of production facilities is relative depending on the purpose of the assessment. The valuation of machines, for example, depends on what needs to be produced. Under this heading, it is not possible to make any other suggestions than general assessments. Attention should be paid to the following aspects: Does the supplier have a full range of machinery to manufacture the required product? How to remedy a possible shortage of machines? Are the machines modern and well maintained (machine breakdown will affect delivery)? Etc.

Human resources

No organization is better than the people who have understood it. Information should be obtained regarding the number of people employed in manufacturing and administration, the use of human resources – whether economical with everyone busy or extravagant with an excess of people doing little or nothing, the names, titles, qualifications, and experience of management personnel, etc.

Quality

The first requirement is that, where applicable, the supplier must have a certified quality system that meets the requirements of BS/EN ISO 9001:2000 (BS/EN ISO 9001:1994 standards remain in force until December 2003, by which time organizations must have upgraded to the 2000 series).

Performance

When evaluating suppliers of non-standard products such as construction projects or the installation of computer systems, you should ask questions about what similar projects the supplier has already undertaken. Which ongoing projects are underway? What are/were the particularities of such projects? Which customers can the supplier cite as references? What innovations could be introduced?

Environmental and ethical factors

The ISO 14001 standard provides guidelines on environmental policies and, where applicable, suppliers must have an environmental policy and procedures in place for the implementation of such a policy. European directives have also issued a large number of regulations concerning air, water, chemicals, packaging, and waste. Relevant questions, in addition to referencing ISO 14001 and EU directives, include: Has the company assigned responsibility for environmental management to a specific person? Do we obtain materials, where possible, from sustainable sources, such as frameworks?

Information technology

Recent research indicates that more than a third of shoppers in the current era are using the internet to conduct transactions and this usage is likely to increase significantly. Additionally, the web also supports a variety of activities such as identifying new sources of supply; finding product information, including product, pricing, and delivery, tracking orders, and receiving technical advice and after-sales service. It is useful to ask mainly open-ended questions under this heading since the answers will indicate the extent to which the supplier exploits the possibilities of e-commerce. Typical questions might be: Does your organization have a website? What information does the website provide? What business activities does your organization process electronically?

The 9 major milestones in a supplier performance management plan

The major milestones in a supplier performance management plan have to include the following:

Figure 3: SPM Plan described in 9 Steps (Gordon Sherry R, 2008)

Initiate project plan and kickoff

The project team and project structure are crucial to determine, as described previously. When the team and structure are in place, the plan is developed and approved. Team members represent key stakeholders, so they should communicate with those stakeholders to ensure buy-in. Obviously, as with any planning, the plan represents an iterative and continuous process and not an end state as in the classic PDCA (Plan, Do, Check, Act) continuous improvement cycle.

Segment the supply base

In determining which vendors to measure, keep in mind the importance of segmenting the supply base. It is the process of classifying suppliers or categories based on common attributes such as dependency, strategic importance, switching costs, and risk. One conducts vendor segmentation to allocate appropriate resources for managing, developing relationships, and working with key vendors to enhance their capabilities and performance. Segmenting the supply base is important not just for SPM, but generally when deciding whether to apply limited liability company resources to work with specific supplier types and vendors.

Develop evaluation strategy

Decisions must be made about the pros and cons of the available approaches to choose which ones will work best in your business environment. Part of choosing evaluation strategies is identifying potential sources of metric data. As part of this, it is important to answer questions such as: Will the information come directly from suppliers, internal systems, users, and stakeholders? Are the tools for collecting this information readily available or will they need to be created? What will work in your business environment?

Define performance expectations

It is essential to define the performance expectations, that is, the areas of competence and the performance standards that you expect from your suppliers. You will need to outline the most critical performance areas for each segment of your supply base that you want to measure. Additionally, you should present the tasks, key decisions, and challenges.

Define KPIs and scorecards

In this step, you will refine the metrics or KPIs that you identified in the last step. These KPIs will help you and your suppliers determine how well suppliers are meeting performance expectations. It’s important to have good reasons for choosing particular metrics other than “It’s what everyone does”. Other companies’ KPIs and dashboards may not apply equally to your company, especially since you need to tie the metrics to your company’s supplier performance expectations.

Develop data collection instruments

When deciding on KPIs, you have to determine how to cool the information that feeds the dashboards. This states that it is important to determine the sources of the necessary information and how you will obtain it. The team can find potential sources of data by accessing information already collected by the company from corporate information systems. They can also directly collect data from suppliers and internal stakeholders using various survey instruments.

Plan transition from metrics to action

Given the goal of measuring supplier performance, which is to uncover and reduce hidden cost drivers and risks, develop relationships with suppliers, and find quality and performance opportunities to pursue, companies are led to plan how they will transform the data and information they collect into actions and results.

Action planning metrics require communications with suppliers to share results and plan improvements, corrective actions, and/or supplier development projects.

Develop SPM business process

The team should consciously develop the SPM business process with a clear plan in mind to ensure clarity in roles and responsibilities for operating and maintaining the system. They must document and communicate the new or revised process, along with any new policies and procedures, to everyone in the organization involved or impacted by it. Suppliers also need to understand the process, as they need to understand new or changed performance expectations, any new rules, and the impact of the process on them.

Conduct SPM pilot

Similar to most key new initiatives, we should roll out SPM in waves rather than implementing it all at once with the Big Bang theory. With multiple functions and stakeholders involved, it’s crucial to start with small successes or manageable failures that can be recovered from, rather than allowing a project to fail. Remember that this is an ongoing and iterative process.

The pilot is the time to test all of the SPM process data collection techniques. This involves using new KPIs and dashboards and communicating with suppliers that we are measuring. Now is the time to troubleshoot the overall process, both internally and externally. Creating a pilot plan is an important task. This plan should involve tasks such as developing pilot goals and critical success factors and selecting pilot vendors. Moreover, It must include evaluation strategies, creating data collection tools for the pilot, internal communications and external, etc.

Summary

In short, we’ve talked about the current state of Supplier Performance Management and introduced the project team, its stages, and structure. We’ve listed criteria for evaluating performance and outlined milestones for the management plan. Remember, keeping track of supplier performance helps companies gain significant benefits. It is important to remember that by continuously monitoring supplier performance, companies can achieve significant benefits listed as follows (Knowledge Works, CIPS) :

- Companies can avoid costly and potentially devastating supply disruptions.

- Companies can reduce the overall risk of other adverse scenarios. Scenarios include defects, and environmental or safety issues with a supplier’s process, materials, or products.

- Companies that successfully implement supplier performance management programs will be better able to detect problems early. Begin implementing corrective actions before the problem becomes a big headache or problem. achieves the bottom line.

References

[1] Knowledge Works, Knowledge How To Appraise Suppliers, CIPS, the Chartered Institute of Purchasing & Supply.

[2] Gordon, Sherry R. (2008) Supplier evaluation and performance excellence: a guide to meaningful metrics and successful results, Library of Congress Cataloging-in-Publication Data.