Your Must-Have Gartner EU Debrief: The TopTakeaways from Gartner Supply Chain Symposium/Xpo EU 2023

Gartner Supply Chain Symposium/Xpo EU 2023 has wrapped up its 3-day event in Barcelona, Spain.

Featuring over 35 Gartner experts and more than 100 research-driven sessions, this year’s conference gathered over 2,000 supply chain professionals from across Europe and beyond.

Our team was energized by the insightful conversations we had and sessions we attended, and we’re excited to share what we’ve learned! The top issue we heard was ensuring resiliency in supply chains today, Decision Centric Planning, followed by the drive to accelerate digital transformation across supply chains, and then day 3’s keynote and a number of user-presented sessions focused on the people managing and the teams working in our supply chain.

Looking for a snapshot of the key highlights? Look no further. Here are the top takeaways we compiled from Gartner Symposium EU 2023.

1. Resiliency and Business Continuity in today’s supply chains.

With the number, frequency and severity of disruptions that can impact supply chain operations growing, now is the time to closely review SCM resilience and business continuity plans. Several of the keynote and analyst presentations focused on the need to build Resilience into your supply Chain to survive and prosper.

We heard how Scenario / Simulations are critical tools to build contingency plans before events happen. The need to identify internal / external potential risks and simulate them within the supply chain digital twin / AI tools that are now available.

- We learned about our new world of VUCA – Volatility, Uncertainty, Complexity, Ambiguity

- That deterministic plans are very traditional and rely on trying to improve the demand forecast and create a plan for the perfect world. We now know that these methods will always break. They are not ready to handle today’s risks and uncertainty. This is 1960’s and 1970’s thinking

- How do we make planning more resilient? With more visibility and predictive forecasting.

- The call to action was to move from forecast accuracy driven planning to resilient planning, where you prepare for many potential outcomes.

- We are proud to note that ToolsGroup has been doing this for over 20 years.

Several use case sessions focused on the Importance of Real-Time Data to capture signals quickly, enabling better decision making faster within the supply chain..

- Analytics in the past were backward looking. Prescriptive analytics. Does not require real-time data.

- Now we are using analytics for predictive purposes, this still does not demand real-time data.

- But we are moving into a world of prescriptive analytics (recommending what to do) and automation (autonomously taking action) and this is where accurate, real-time data is absolutely essential.

- Bridgestone talked about their system where they dynamically optimize availability, cost, cash and CO2

Lucky winner Nelly Durant, Kimberly Clark Corporation joins ToolsGroup’s Kevin Young at our booth wearing her newly won Ray-Ban sunglasses!

2. The building momentum to adopt decision-centric planning.

Decision-centric planning has gained traction in situations where the standard S&OP process is too rigid to handle the real-time decisions that need to be made. Here’s what it involves.

- Monitoring events. Continuously monitor events to decide when to do a planning run.

- Assessing event impacts. Start with the basic questions: Is it a strategic or tactical impact? What process needs to be initiated and who needs to be involved?

- Acting on that assessment to make decisions. Define the thresholds and guidelines for actions. This gives you the largest margin of time for making a decision, which is often better than making decisions too quickly before you can see the full picture.

- Implementing decision-driven composable processes. This requires breaking S&OP and S&OE into smaller processes and pulling them together as needed to address the issue at hand.

This helps bring in all the necessary parties and information needed for making fast, accurate decisions while remaining flexible and adaptable.

Quote from a CSCO: “In our monthly S&OP meetings we hardly ever have time to get to the strategic decisions. We get bogged down with immediate tactical challenges, and that is not the best use of my time.”

Kevin Young, ToolsGroup CMO introduces illycaffè session, “How to navigate market uncertainty and guarantee product availability.”

3. The increasing urgency to drive Digital Transformation across the supply chain.

Several end-user case studies were presented on how they are driving Increased urgency to speed up digitization and automation. Traditional methods and manual integrations are breaking with the disruptions that seem to be coming more frequently of late. If you are to build a truly resilient supply chain, it has to be digital and automated, preferably with AI to enable making the best decisions at web speed. Companies must therefore also invest in intelligent and connected infrastructures to bring it all together.

Illycafe presented their digital transformation journey and shared their top 3 suggestions:

- Accelerate Planning to Tackle Growing Complexity – Adopt flexible tools and processes that can handle rapid changes in direction and keep up with the speed of market changes.

- Embrace End-to-End Optimization – Use probabilistic forecasts to improve planning throughout the entire supply chain and across all planning and execution functions.

- Employ Collaborative, Knowledge-Sharing Processes – Communicate a shared vision across all teams. Build interconnected systems that break silos and support collective decision making.

Andrea Fabro, Demand & Operations Planning Manager, illycaffè noted – “Our long-time partnership with ToolsGroup helped us deliver a superior consumer experience, even in the midst of the pandemic, and continues to sustain our high standards for customer satisfaction and efficient inventory management across our network.”

Andrea Fabro’s insightful presentation on digital transformation drew quite a number of attendees.

4. Probabilistic forecasting continues gaining momentum.

Amber Salley and Noha Samara hosted sessions focused on moving from deterministic to stochastic / probabilistic approaches, to better deal with today’s disruptions and volatility, increasing resiliency.

Forecast accuracy is foundational for the supply planning process, and we noticed that many supply chain executives are beginning to more seriously consider the great advantage probabilistic forecasting has over traditional forecasting methods, especially in continuously turbulent times.

This AI-driven forecasting method incorporates data from a broader range of sources to generate a range of probable forecast outcomes and calculate the likelihood of each.

This deeper understanding of customer demand translates into a more effective inventory strategy, especially for items with intermittent demand (which often end up comprising the bulk of excess inventory).

Smarter forecasts result in better inventory management (and in turn, happier customers and wider profit margins).

Still new to probabilistic forecasting?

5. The people Potential in Supply Chains

Right from the opening keynote on “Unlocking the Collective Potential of the Supply Chain”, speakers both from Gartner and use sessions noted that we need to focus on the people in our supply chain teams, not just the technological aspects to be successful.

Key takeaways from Thomas Pocock, Senior Director, Advisory, Gartner Keynote session included:

- “Supply chain leaders must reevaluate how they look at the individual, community and technological potential available to them in order to achieve a new peak of productivity to enable their objectives and break out of a pattern of low and stalling labor productivity.”

- “It’s time to enable individual employees to achieve their full potential at work and in life by investing in radical flexibility.”

- “In practice, organizations have embraced radical flexibility by breaking down projects into component skills, or even breaking down previous single roles into component parts for multiple people to fill.”

- “To combat change anxiety and overload, supply chain leaders must design opportunities for humans and machines to learn from one another in a safe environment.”

We regularly heard that SCM professionals need to be, as well as build more “human leaders” to secure supply chain talent and accelerate digitalization. People are key to successful and resilient supply chains. Several sessions shared how to be more inclusive and expand with Diversity, Equity and Inclusion (DEI) efforts; as well as how to redesign processes and to unlock the collective potential.

Several speakers noted the need for increased flexibility (role vs. job specialization, self-organizing vs. hierarchy / silos).

We also head about AI and how it can make our teams much more productive with automation.

Faced with the increasing prevalence of escalations and with major, frequent shifts in demand, planners are under a tremendous amount of pressure. This can lead to inefficiencies in planning as well as high turnover. By automating grunt work and complicated calculations, innovative planning systems help planners manage by exception, addressing issues that require human intervention while letting machines do the heavy lifting and reduce planner workload.

At the end of the day, it is the people that make or break the success of our supply chains, and we always need to remember that..

Our Supply Chain wheel is packed up and we are thinking about heading home, but first we sat together to compile the results of our Supply Chain wheel.

As we did in Orlando, we had some fun at this year’s conference with our Supply Chain Wheel, which attendees could spin to also win a prize!

As we did in Orlando, we couldn’t pass up the opportunity to also do a little informal research of our own.

Read on to discover our insights and the results of our contest!

ToolsGroup SCM “Spin the Wheel!” Contest Results

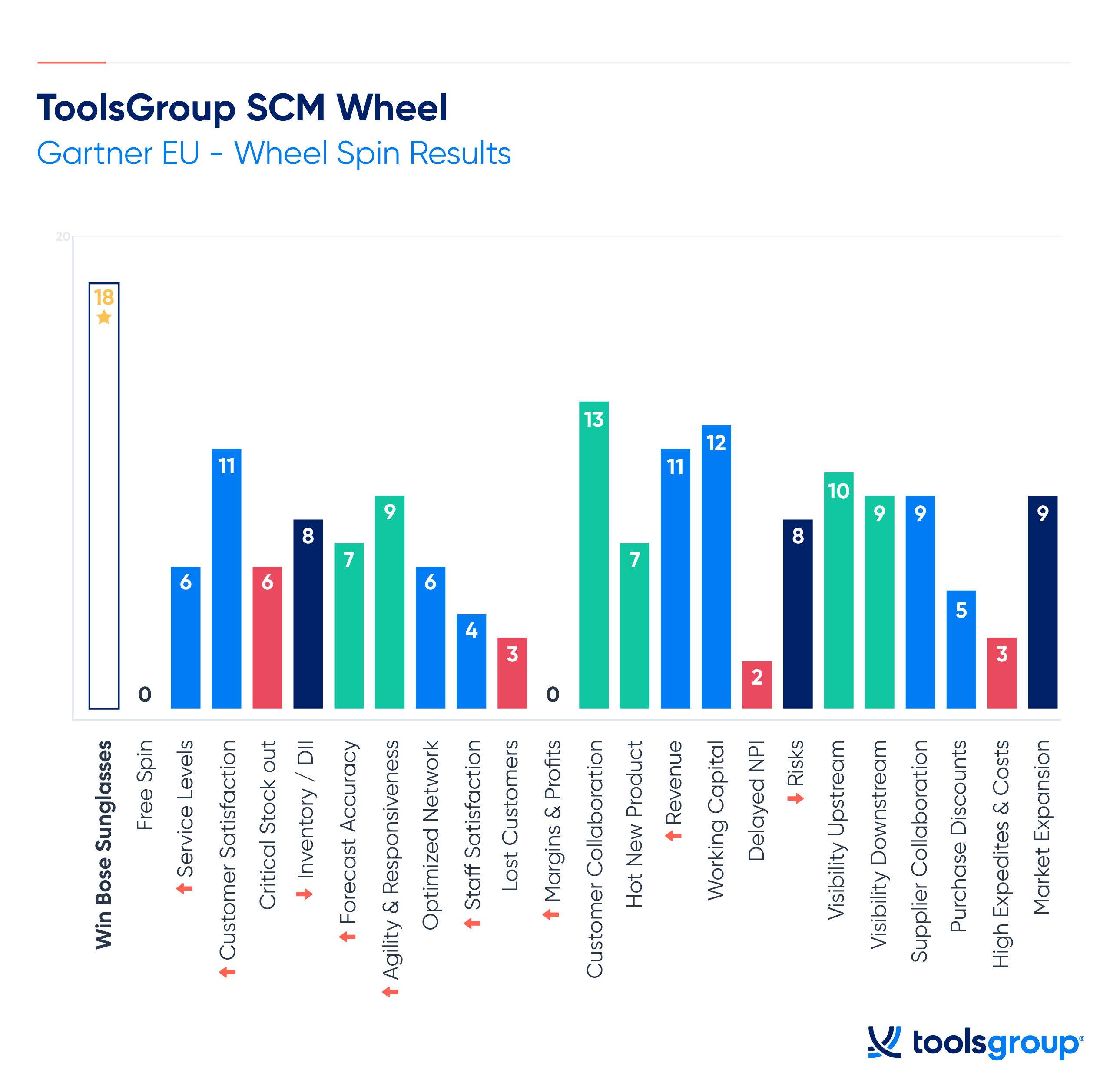

We had 174 Gartner EU attendees spin the Supply Chain wheel, with 18 winning a combination of Bose Bluetooth Sunglasses or Ray-Ban Sunglasses! That certainly beat our Gartner US SCM wheel spins by over 25%, even with 85% more attendees in the US. Seems our European attendees were much more interested in what our SCM wheel was predicting their top KPI might be!

We also gave away 167 Amazon gift cards. The ToolsGroup SCM wheel launched many great discussions around which KPIs attendees were most focused on to improve in 2023 and into 2024.

Even though they could not win a gift, we want to thank the onsite Gartner analysts and associates, as well as many other exhibitors for also having some fun with our wheel and sharing their thoughts and inputs on key SCM drivers.

ToolsGroup’s Dafna Shamir with Alex Moss showing off his new Ray-Ban sunglasses

Attendee Results: “What is YOUR most important Supply Chain KPI to improve this year?”

While we received a broad variety of answers to the question of KPIs, we did record a 74% consensus around just six KPIs.

38% of the respondents picked Increase Customer Satisfaction or Increase Service Levels reflecting one of the top themes at the event, customer-focused supply chains and resiliency.

Next up in frequency were our business related KPIs – Improve Working Capital, Reduce Inventory, and Increase Margins & Profits reflecting another key theme we heard given today’s economic times, a focus on the critical business KPIs (also one of our key takeaways from the event!).

Rounding out our top KPIs are Forecast Accuracy and Agility & Responsiveness, which both are very closely related to our top 2, focus on customers’ themes!

Check out the graph and see where your key goals fall versus our Gartner Symposium SCM wheel participants.

Wheel Spin Results: Wondering what attendees were spinning?

Most of the results were pretty evenly distributed with just a couple of hot spots. One hotspot was right at our Sunglasses winning slice, which our eighteen winners really appreciated!

Two other popular spins were Customer Collaboration and Satisfaction. In fact, on Tuesday the SCM wheel exactly matched the KPI goals for 18 attendees. Its telepathic results became a point of keen interest that afternoon.

Contrasting Gartner US in Orlando, with Gartner EU in Barcelona, focus areas reported were generally very similar with Customer KPIs at the top, but our European participants were a bit more focused on the business KPI’s of overall Working Capital and focus on Improving Margins & Profits, over some of the other more tactical KPIs.