Table of Contents

** Minutes

The history of billable weight

How is billable weight calculated?

Billable weight calculation examples

3 ways you can reduce shipping costs (+ better packaging options)

Package the items, weigh your shipment, and get a rate.

Calculating shipping costs is easy, right?

If you’re familiar with shipping orders, you know it’s a bit more complex than that.

If you are new to ecommerce, you might think that your shipping costs always depend on the actual weight of the shipment (outside of flat rate shipping). However, the actual weight is only one part of the equation as far as understanding what your shipping cost will be.

In addition to actual weight, shipping carriers also take into account what’s known as “billable weight,” which relies on a few other factors, including dimensional weight or the dimensions of your package.

In this article, learn what billable weight is, how it’s calculated, and what you need to know to optimize shipping costs.

What is billable weight?

Billable weight is a pricing technique used by carriers to calculate shipping rates per package, taking into account both dimensional weight (the length, width, and height of a package) and the actual weight of the shipment.

Whichever weight is greater will be used as the billable weight for your shipment, leading to the actual shipping rate.

The history of billable weight

Until 2015, carriers used a package’s actual weight and shipping distance to calculate its shipping costs.

After realizing this cost model didn’t make sense for lightweight packages that took up cargo space and reduced the carrier’s capacity, they transitioned to billable weight for shipments 16 ounces or greater.

A common problem that carriers also faced was that shippers didn’t optimize their packaging for small items because they weren’t being charged for their package dimensions.

That’s when carriers decided to add the DIM factor (the value used to calculate the dimensional weight of an object) in calculating shipping costs. Dimensional weight calculations enable carriers to take into account the package’s weight and its density (amount of space) as well.

How is billable weight calculated?

To calculate billable weight, you will need both the actual weight of the shipment along with the dimensions of the package in inches.

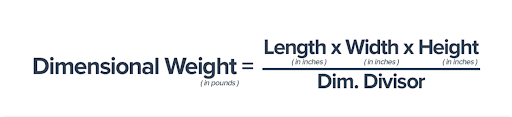

Billable weight is calculated as follows:

(Length x Width x Height) / DIM Divisor

To truly understand how billable weight works, let’s dive into how dimensional weight and actual weight is calculated.

How dimensional weight works

Dimensional weight is calculated by measuring the cubic size of a package and dividing it by a dimensional factor, commonly known as a DIM divisor.

Here’s the step-by-step process to calculate a package’s dimensional weight:

- Measure the length, width, and height of a package, using the longest point on each side.

- Next, multiply those dimensions to get the cubic size of the package.

- Divide the cubic size by your carrier’s DIM divisor.

Note: FedEx’s DIM divisor is 139 for all services. UPS’s DIM divisor is 139 for daily packages and 166 for retail packages. USPS’s DIM divisor is 166.

How actual weight works

Actual weight of the package is calculated by placing a package on a scale, recording the weight of the package, and then rounding that number to the next whole pound.

Billable weight calculation examples

As you get familiar with the concept of billable weight, it may be helpful to see a few examples of billable weight calculations in practice.

Example #1: Stuffed Teddy Bear

Let’s take the example of a large stuffed teddy bear, which is a lightweight item that has long dimensions. We’ll also use the DIM divisor 139 to calculate the DIM factor of this particular shipment.

| Length | 15.07 inches |

| Width | 10.31 inches |

| Height | 7.28 inches |

| Dimensional Weight | (15.07 x 10.31 x 7.28) / 139 = 8.1374 lbs |

| Actual Weight | 2.77 lbs |

| Billable Weight | 9 lbs (dimensional weight rounded up to the nearest whole number) |

As you can see from this example, while the teddy bear may be light in weight, its larger dimensions determine its billable weight for shipping and will be billed as such.

Example #2: Dumbbell

Dumbbells are heavy items with relatively smaller dimensions — it’s likely that the actual weight of the dumbbell will be greater than its dimensional weight.

We’ll use the DIM divisor of 139 in this shipment example to offer a side-by-side comparison to our teddy bear example.

| Length | 10 inches |

| Width | 9.17 inches |

| Height | 4.65 inches |

| Dimensional Weight | (10 x 9.17 x 4.65) / 139 = 3.0676 lbs |

| Actual Weight | 11 lbs (10.32 lbs rounded up to the nearest whole number) |

| Billable Weight | 11 lbs |

This example confirms our initial hypothesis — the dumbbell’s actual weight far exceeds its dimensional weight and will be used as its billable weight for shipping.

3 ways you can reduce shipping costs (+ better packaging options)

Now that you better understand how to calculate the billable weight and when it’s used, you can optimize your shipping strategy by reducing costs.

Here are a few ways you can optimize your billable weight and reduce shipping costs:

1. Review your packaging options

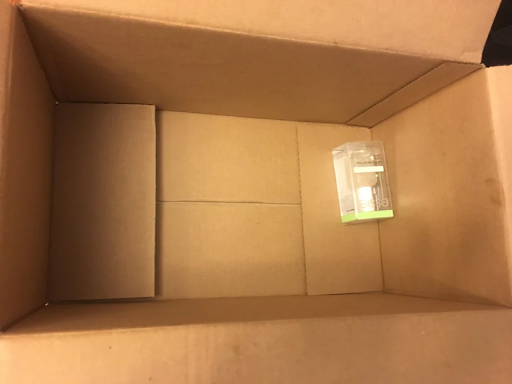

One of the most common mistakes businesses make when they ship their products is using the wrong packaging for their items.

It might be less of a headache for you to use boxes to ship all your items, but since carriers are evaluating the dimensional weight of your packages to arrive at your billable weight, this approach could end up being more expensive for you.

And not only is it more expensive, it also doesn’t make for a great customer experience (see below).

(Source)

You might also end up using more shipping supplies, such as dunnage and other packing material than you would need if you used the appropriate packaging, which further also adds to your shipping costs.

By reviewing your packaging options, you can be more intentional about the packaging you use for each of your shipments, thereby reducing your billable weight and your shipping costs. But it can be hard to track and predict shipping costs when every shipment can vary in weight.

However, a 3PL like ShipBob can help make the process easier. For instance, ShipBob’s Box Selection algorithm and our Cubiscan machines use actual product dimensions and your packaging preferences to tell us which package size we should use for any order combination, so your orders will have consistent pricing.

2. Switch from boxes to poly mailers

Boxes come in standard dimensions, aren’t flexible, and require ample dunnage to ensure products are secure during transit. If you’re shipping products like t-shirts, boxes may increase your dimensional weight and add to your shipping costs.

Poly mailers or poly bags are smart and affordable alternatives to boxes to reduce your shipping costs. They’re lightweight and sturdy, take up less room than a box, have a self-sealing foldover lip, and some even come with bubble wrap padding built-in as well.

Poly mailers are flexible and don’t require additional dunnage for shipping, which is why they’re the preferred choice to apparel retailers, for example, where the products are not as susceptible to damage while in transit.

To help merchants ship packages out using the optimal packaging, ShipBob offers both bubble mailers and regular poly mailers as part of their standard packaging options in multiple sizes.

Of course, not every type of product can be shipped in a poly mailer (take glassware, for example), but they’re worth adding to your packaging mix so that you can reduce your billable weight as much as you can.

3. Use ships in own container (SIOC) packaging

SIOC is a form of product packaging where the product ordered can be shipped to the customer in its original packaging, without any additional packaging required such as an overbox. A common example of this is a product that is stored in a box (e.g., a pair of shoes).

Not only does this reduce redundant packaging but it potentially saves money by reducing the billable weight.

4. Partner with a 3PL

Though there are ways you can reduce billable weight and shipping costs by yourself if you’re currently fulfilling orders in-house, you can potentially save time and money by partnering with a 3PL like ShipBob.

3PLs stock a variety of packaging solutions for their customers and they have the expertise needed to recommend the right packaging option for your products.

You might be torn between different box dimensions and void fill options, so having a professional 3PL who knows what they’re doing can get you shipping faster, cheaper, and more efficiently.

Tech-enabled 3PLs like ShipBob also offer insights into important distribution metrics that you can use to make informed decisions, such as how much your average shipping costs are.

“Before ShipBob, we used to work with another 3PL that was terrible. It was so stressful trying to deal with them. The old 3PL charged for each pick and pack, wouldn’t take responsibility for any errors they made, and getting orders fulfilled would take up to 20 days in some cases. I’m super happy we switched to ShipBob. We got a fresh start, and it was a very smooth and easy transition.”

Torii Rowe, COO & Co-Founder of MANSSION

How ShipBob works to optimize your shipments

At ShipBob, our job goes beyond providing premium retail fulfillment solutions. Our goal is to provide you with the infrastructure, technology, resources and customer support needed to grow your business.

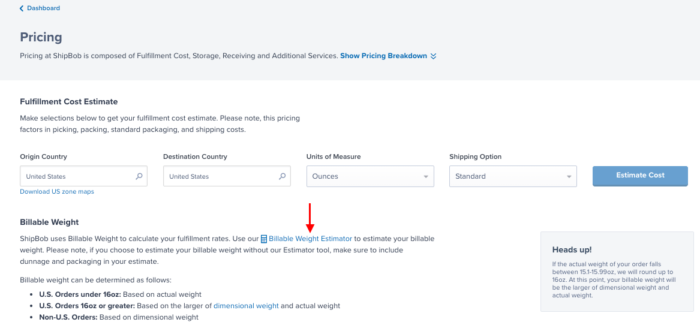

With ShipBob, billable weight is calculated as follows:

- US shipments under 16 ounces: Based on actual weight

- US shipments 16 ounces or greater: Based on the larger of dimensional weight and actual weight

- International shipments: Based on dimensional weight

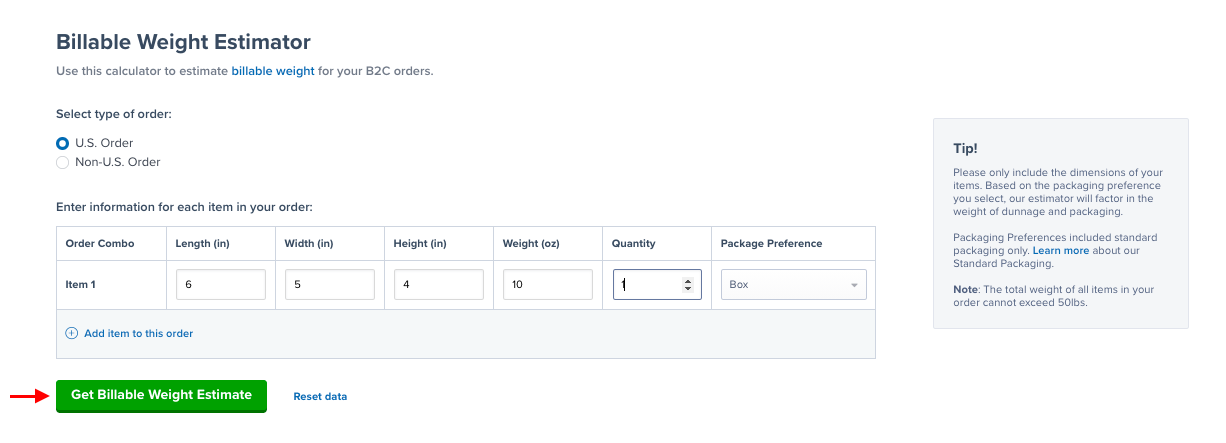

To help you track and optimize shipping costs, ShipBob provides you with a Billable Weight Estimator, which makes it easy to calculate your shipment’s billable weight as part of your fulfillment costs.

The Billable Weight Estimator works in two steps:

- Enter your product information.

- Estimate your shipment’s billable weight.

Here are some additional ways in which ShipBob can help you optimize logistics costs, from transparent pricing to packaging solutions.

Transparent billing options

ShipBob prides itself on offering customers transparent pricing that do not fluctuate at every turn (with hidden costs and dozens of fees).

If you have unique needs, such as custom packaging, kitting and bundles, custom packing slips, etc., ShipBob can accommodate your business at an additional cost. Quotes are customized to fit each merchant’s individual needs.

From the ShipBob dashboard, you can view a billable breakdown, including:

- Total monthly costs by fee type

- An itemized record of charges for each month

- Average fulfillment cost per order

- Fulfillment cost per shipping option

- And more.

“Speeding up deliveries and keeping them affordable for customers is a top concern for us. With ShipBob, we can comfortably assign a shipping cost to each order by pinpointing the product weight and destination zip code.

In comparison to shipping products to the US from Canada, which can be extremely variable in cost, fulfillment by ShipBob is much easier to estimate because we know the true fulfillment cost.”

Greg MacDonald, CEO & Founder of Bathorium

Find the best carrier options

ShipBob handles the stress associated with shipping by partnering with major shipping carriers, as well as regional parcel carriers to provide you with discounted shipping rates.

Our carrier partnerships enable you to offer more shipping options for your customers at affordable rates.

ShipBob even offers visibility into real-time carrier rates that you can display within your store during the checkout process. When it’s time for ShipBob, our automated shipping technology identifies the most cost-effective route for every shipment.

“Pillows are not small items, which makes them difficult to store and expensive to ship because of dimensional weight. Even though they are lightweight, they are big, so you pay for the space they take up on a delivery truck.

And the farther away the shipping destination is, the more expensive it is to ship them. I knew I needed a cost-effective way to help me ship pillows at launch, and it turns out ShipBob was it.”

Tracey Wallace, Founder of Doris Sleep

Provide custom packaging solutions

ShipBob also works with you to identify the best packaging option for your products. We take into account product integrity, order history, shipping costs, and the customer experience to recommend the optimal packaging solution for you.

With ShipBob, you have the option to choose standard packaging at no extra cost, or you can opt in for custom packaging, such as branded boxes or eco-friendly packages to enhance the unboxing experience.

“ShipBob supplies a range of standard box sizes, but because some of our products have such unusual dimensions, some of our shipments were being sent out with lots of empty space, leading to higher shipping costs.

Our Merchant Success Manager provided us with an in-depth analysis based on our order history and helped us understand which custom box sizes we should stock ourselves at ShipBob warehouses to help reduce our costs. We have come to really appreciate this level of visibility and control merchants are given over how items are packed prior to shipping.”

Demand forecasting technology

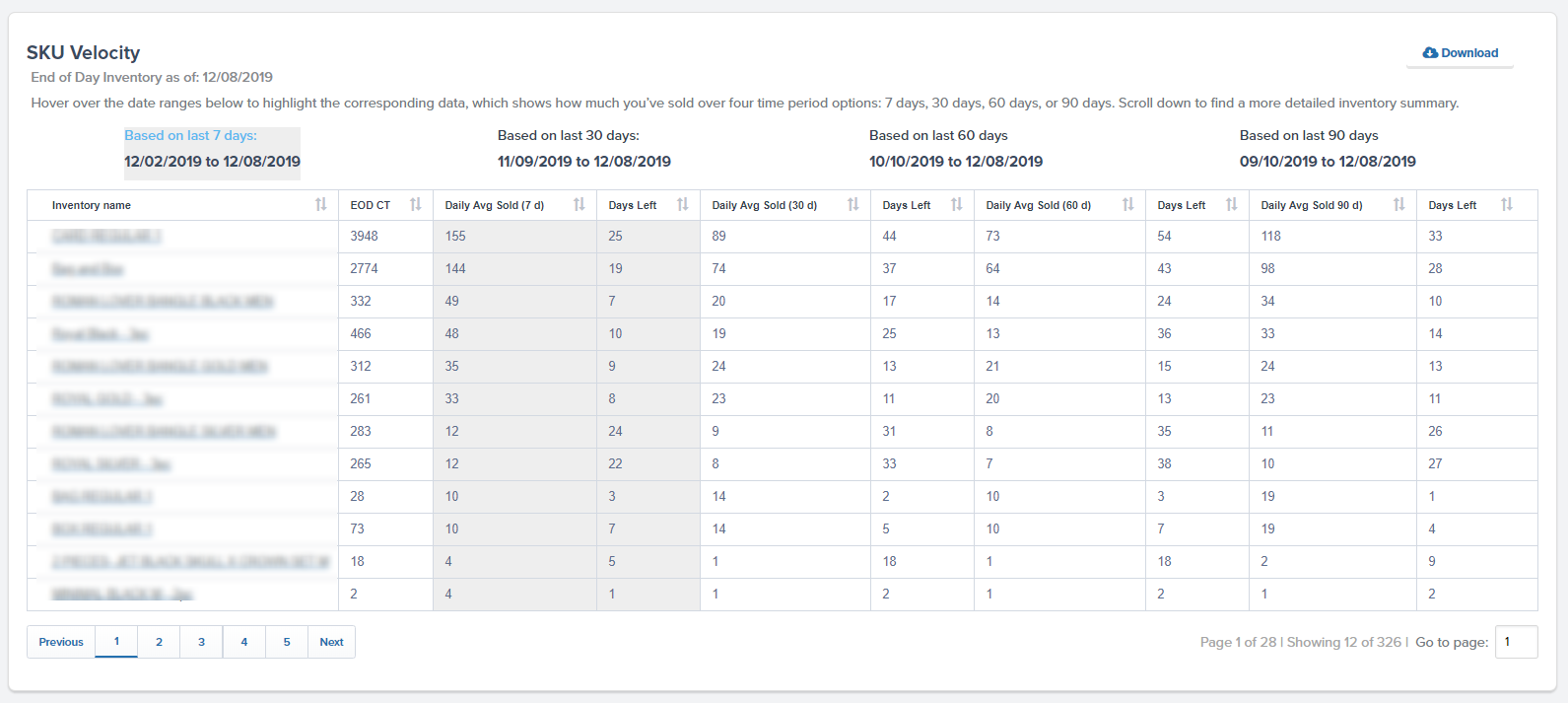

Since ShipBob’s entire logistics network is powered by proprietary fulfillment software, you’re given access to real-time inventory analytics, which provides the insights you need to forecast demand.

Using ShipBob’s data and analytics tool, you can get answers to questions like:

- How quickly products are selling

- Which items are slow-moving

- How many days of inventory you have until you are expected to run out (based on SKU velocity)

- How your current demand compares to previous time periods

- How your sales are affected by different seasons and months

- And much more

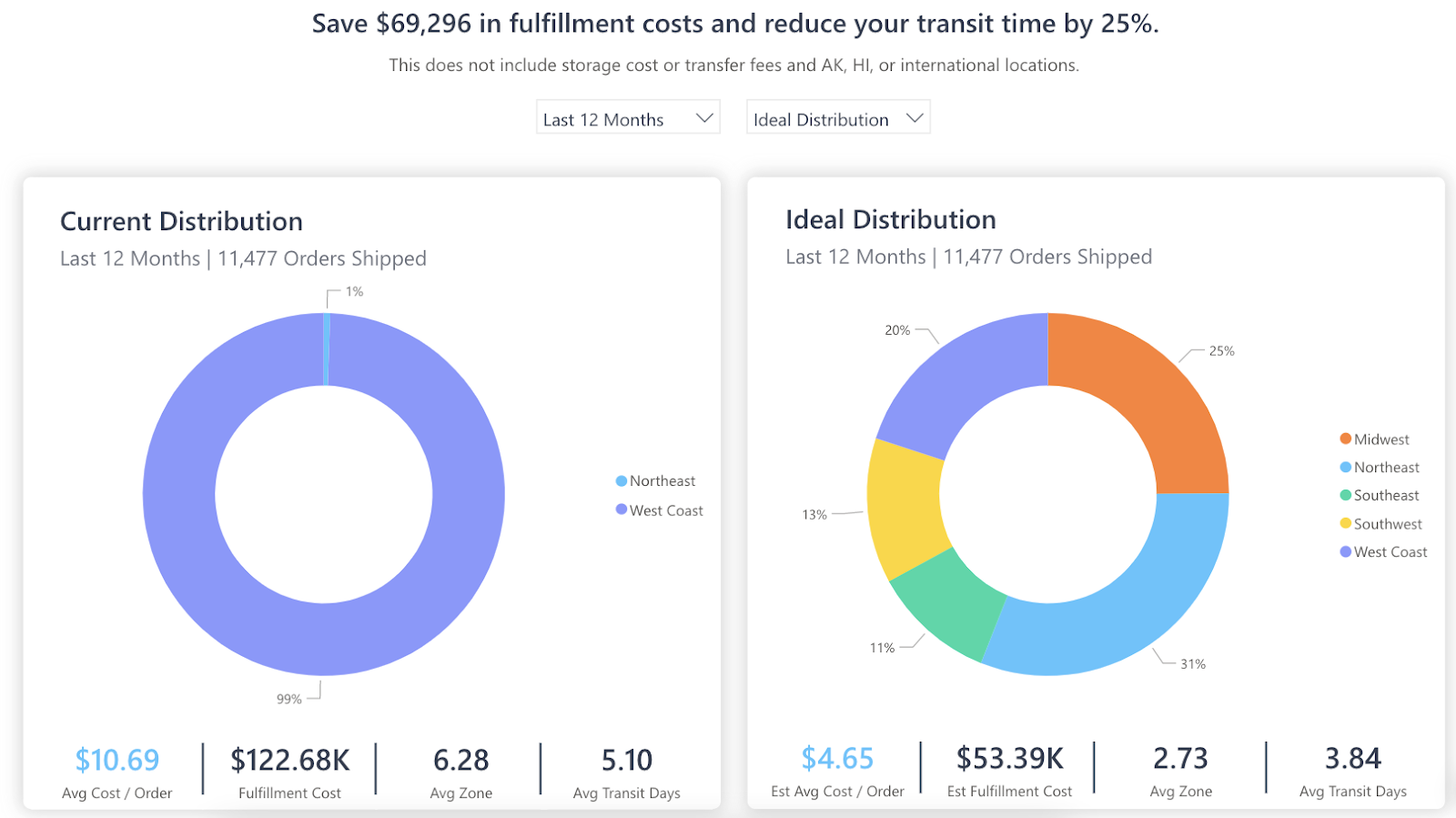

Reduced shipping zones

With ShipBob, you can store inventory throughout all of our locations in the United States (as well in Canada, Europe, and Australia), which allows you to get products to your customers faster than you could by keeping them on hand and fulfilling orders yourself.

Once you’ve started shipping with us, you can start to collect and analyze shipping performance and access data that provides insights into your ideal inventory allocation and distribution.

You can compare your current fulfillment center(s) and shipping costs to any combination of our other fulfillment centers and how much it would have cost to ship your orders out of those locations.

This helps you make informed decisions around which ShipBob fulfillment centers to store inventory in based on where your customers are located.

From there, orders can be fulfilled and shipped from the nearest fulfillment center, which reduces the amount of shipping zones a package must travel through to reach its destination.

By creating an ideal distribution strategy, you can enable affordable 2-day shipping via ground by costs and speeding up last-mile delivery.

“Running an Austin-based company, it’s convenient to use ShipBob’s Dallas fulfillment center. A big part of my strategy right now is focusing on Texas, because it’s expensive to ship large packages to other areas of the country.

Using my order history, I can understand which ShipBob warehouse I should use next and leverage their locations all over the US as Doris Sleep continues to expand. The numbers pull through easily and keep me informed.”

Tracey Wallace, Founder of Doris Sleep

Check out the full list of ShipBob’s locations here.

Whether you’re currently fulfilling orders yourself, or you’re an established ecommerce business looking to switch 3PLs, ShipBob can help.

To learn more about ShipBob’s best-in-class order fulfillment solution, click the button below for more information, including custom pricing.

Billable weight FAQs

Here are answers to the top questions business owners have about billable weight.

How can 3PLs help you reduce billable weight costs?

3PLs can help businesses reduce their billable weight costs by:

- Recommending custom packaging options to reduce dimensional weight of shipments.

- Offering packaging alternatives, like poly mailers instead of boxes.

- Negotiating more favorable billable weight calculations for carriers.

What’s the difference between dimensional and billable weight?

Billable weight is often calculated as the greater of dimensional weight and actual weight of a shipment. Dimensional weight is a metric used to determine the billable weight of a shipment, and is calculated by measuring the cubic size of a package and dividing it by a dimensional factor, commonly known as a DIM divisor.

How can you optimize your packaging options?

To optimize packaging, you will have to take into consideration how long the shipment will be in transit before it reaches its destination and how fragile the items are. ShipBob makes it easy to optimize shipping and packaging by using a Box Selection algorithm, which uses dimensions and your packaging preferences to tell us which package size we should use for any order combination, so your orders will have more consistent fulfillment pricing.

What’s the best way to calculate billable weight?

To calculate billable weight, first identify dimensional weight (the length, width, and height of a package) and the actual weight (what the shipment actually weighs). The greater amount is the billable weight.

How does UPS calculate billable weight?

For domestic and international shipping via UPS, the billable weight will be the greater of the dimensional weight compared to the actual weight, which is used to calculate the shipping rate. Click here for more information.