This post has already been read 14511 times!

It’s fair to say that few industries have escaped the massive disruptions that have plagued the supply chain in the last couple of years. Many leading experts are reporting that disruptions will continue and could be more devastating than what we have experienced recently. It is also likely that the Automotive industry likely to suffer more than most.

Supply Chain Trends and Challenges in the Wake of COVID

Whilst COVID has played a huge role in these disruptions, other factors have caused massive issues for companies in their efforts to source, make, and distribute product. These disruptions have not and will not be limited to one resolvable issue. So, for those thinking, “it will settle down soon,” I am afraid they could be in for a long wait.

There issues growing in severity related to many factors; such as, the global economy, regional economies, exponential growth and loss across businesses, government legislation, climate change, war and conflict, changing consumer demand… the list goes on.

Some industries that have the luxury of being more stable have been able to weather the storm and have seen some benefits during these uncertain times. Survival of the fittest often doesn’t just equate to “survival,” but for the fittest it can often mean to thrive.

Major issues that continue to effect supply chain, both positively and negatively depending on your industry, are things like: panic buying, which has become more common place; financial management within the home has become far more important; people are more aware of their impact on earth; governments are more accountable and obliged to be more transparent.

In the wake of these trends, and with more fierce competition, some businesses are disappearing entirely, while others are indeed thriving.

However, even companies doing well have issues. I have spoken to many thriving companies that are struggling manage and control that growth. Managing rapid growth, especially when it’s unpredictable, can be a major problem, and some companies are now finding their supply chains are straining and buckling.

Many of these companies are now in a desperate bid to retain that growth and ride that wave but find themselves ill-equipped to do so. This is often exacerbated by legacy or inappropriate technology.

The Automotive Industry is Particularly Vulnerable

Then of course there are the less fortunate, companies who have been hit hard by changes and disruptions, and continue to be overwhelmed by them, such as the Automotive Industry. We live in a world where the smallest issue can result in a catastrophe for a business. If something catastrophic happens to a trading partner, it’s almost certain you will be affected too. Never before has the term, “you’re only as strong as the weakest link” been so true. As cars have incorporated more electronics and computerization, so their complexity has increased. We’ve seen the huge impact that a shortage in these critical components can have on vehicle production and sales.

A recent report highlighted that 80% of the data needed to manage the end-to-end supply chain process sits outside a company’s enterprise, and therefore is outside your sphere of visibility.

Collaboration is key. Let me rephrase, network collaboration is key! After all supply chain is a collective operation.

Why It is a Critical Time for Automotive Companies – a major change is rippling through the automotive industry, loosening customer loyalty to brands, and forcing companies to embrace new technologies while supporting old ones. Click To TweetIn addition to the above, there is another factor that makes Automotive OEM’s and Suppliers particularly vulnerable. The Automotive Industry is going through a major change. The next ten years will see the Automotive industry change dramatically, as electric vehicle sales are predicted to surpass those of combustion vehicles, and companies find themselves having to support that transition. It’s not simply a case of moving to electric vehicles, but supporting the innovation that comes with a new industry, as well as supporting the decline of another. Automotive OEM’s will need to do both successfully if they are to thrive.

In rugby there is a term used in every game, “turn and face”, this refers to when you’re retreating or walking backwards to prepare for a new phase of the game, you must continue to face (“turn and face”) what is coming at you so you can react should the opposition suddenly attack. This is what OEM’s will need to do, as they walk towards a new world, they must continue to face the old. This will be a massive challenge and those that thrive will need every part of their business firing on all cylinders to do so.

We have seen a huge change in buyer behavior in recent years, brand loyalty has declined, consumers no longer want to wait, nor are they prepared to risk waiting.

However, people are loyal to brands that require large investments, like cars, and some are prepared to wait to get their preferred brand. But that wait time is growing, pushing consumers to consider alternatives. This is being heightened by the huge transformation of moving away from petrol and diesel to electric. In the next decade or two, we could see the death of a number of car brands, and the birth of many new ones.

Supply Chain’s Role in Your Success

The major underlying factor in all this is the supply chain. Any supply chain is a company’s central nervous system. It’s of vital importance, it can save you, or kill you. In the Automotive world supply chains will play a particularly vital role.

Your supply chain can help grow the business and support that growth, adjust to minimize losses when disruptions occur, find new opportunities, support your trading partners and in turn help them grow and manage that growth. It needs to react to changes, support innovation, support the transition from one process to another. Without a robust supply chain, you will not thrive, you may not even survive.

Why It is a Critical Time for Automotive Companies – supply chains will play a critical role in supporting and smoothing the transition to electric vehicles, and attracting new, loyal customers to brands. Click To TweetThe next ten years are of crucial importance. Retaining and acquiring new “brand loyal” customers will see some automotive manufacturers thrive in this transition. But this is only possible with a robust, advanced, agile, responsive, collaborative supply chain, and that means a supply chain network.

How connected to your entire supply chain are you? How collaborative is the end-to-end process? How much visibility and control do you have? Are you simply one company sat in a line of others, shoulder to shoulder, when you should all be sat around a table together, all looking at the same data in real time? How agile are you? Can you resolve an issue before it impacts you and your partners? How healthy is your supply chain and is it ready for what is going to be the most volatile, disruptive, challenging (but also potentially rewarding) time in your company’s history?

Not only is it time to transition to a new automotive world, one which I am sure you’re already preparing for, but this is also the time to re-evaluate your supply chain.

Let’s start at the first step. A supply chain will never be successful if you approach it as a chain. The truth is, it’s a network. A network of companies all striving to support the common goal, a team working to deliver the highest quality products and services, at the lowest cost. In order to succeed, it’s vital that you’re all connected, sharing data and processes to support one another.

One Network was founded and built to help companies achieve that.

The Digital Supply Chain Network Solution for Automotive Supply Chains

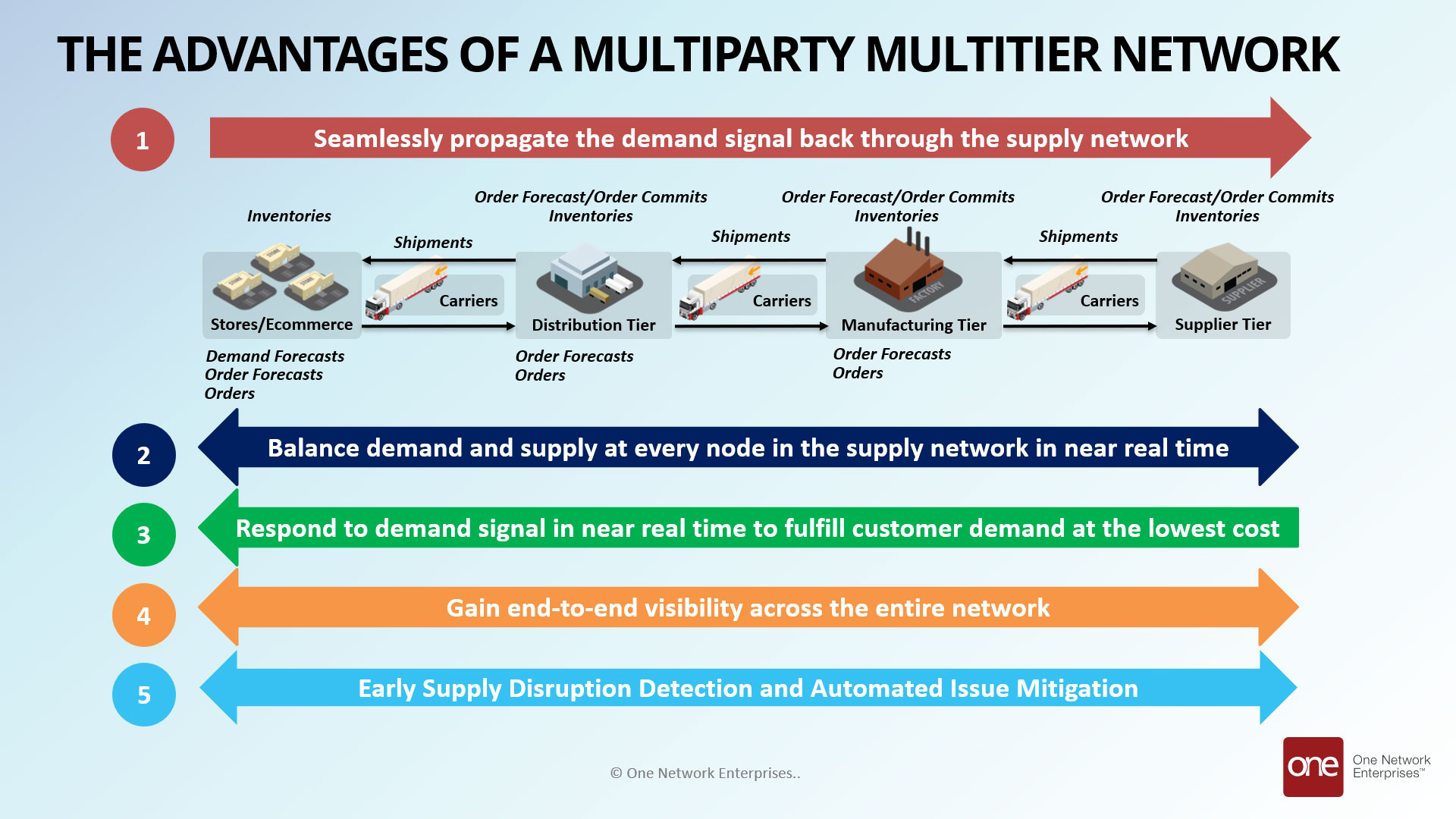

The Digital Supply Chain Network™ enables companies to collaborate with all their trading partners from end-to-end and through every tier. That means OEMs are no longer blind to supply constraints upstream, beyond their subsystem suppliers. And all tiers of suppliers have visibility to demand downstream and can plan accordingly. Not only that, they can collaborate directly to ensure alignment across all nodes and tiers, to drive more realistic and executable plans, and to collaborate during execution.

This is all possible, only because the network uses a single platform with one data model that delivers a single version of the truth. This multi-party, multi-tier, real-time digital network connects parties not in a hub-and-spoke manner, but as equals, hub-to-hub. It also integrates seamlessly with existing ERP systems. This creates more accurate demand forecasts, enables integrated business planning and execution, as well as global supply to demand matching.

Why It is a Critical Time for Automotive Companies – The Digital Supply Chain Network with its single data model and a single version of the truth for all partners, enables the necessary multi-tier visibility and collaboration so vital to… Click To TweetCompanies on the network use One Network’s Intelligent Control Towers powered by NEO, One Network’s AI and machine learning technology. Because NEO Platform uses a real-time, single version of the truth network approach, it removes system lead times and provides real-time visibility to critical events, as well as the ability to respond and collaborate in real-time, enabling agility to all trading partners. It also provides predictive and prescriptive analytics, so all trading partners are informed of potential issues and are provided with practical resolutions, based on current states and constraints in the supply chain.

The network approach enables seamless planning and execution, based on accurate, near real-time data, enabling companies to improve their service while lowering their operational costs. Companies on the Digital Supply Chain Network see improved on-time deliveries, reduced order-to-ship time, reduced transportation costs, and have real-time visibility to inbound supply and can orchestrate it to minimize disruptions.

Some of the more unique aspects of One Network’s Digital Supply Chain Network include:

A Single Data Model for the Supply Chain – The network uses one fully integrated multi-tier, multiparty single data model from the consumer to the supplier and all logistics partners. The platform is not an amalgamation of separate systems. There are no data silos or information lags between planning and execution capabilities. It digitizes the entire business network across demand, logistics and supply, so all parties can see, collaborate and respond, to optimize service levels and product quality at the lowest cost.

NEO AI and ML Intelligent Agents automatically provide predictive analytics and prescriptive resolutions. Projected problems are found quickly, and a fix to the problem is either automated or, at most, three clicks away. So, problems are found early and resolved quickly, while there are still low-cost options.

Zero Latency – Information lead times move from days to near real-time on the network. Demand intelligence flows in near real time, to you, your suppliers, and your suppliers’ suppliers. Similarly, supply problems are propagated downstream, in near real time, to all relevant parties, enabling them to adjust plans accordingly.

Digitize the Automotive Supply Chain and Transform or…

Whatever automotive companies decide to do in the coming years, they will need to move quickly.

The beauty of the Digital Supply Chain Network, is that it facilitates rapid on-boarding and digitization, not just of the enterprise, but of the entire trading network. It is already a thriving community of tens of thousands of companies and carriers. Newcomers need to connect only once to gain immediate access to data from every partner already on the network. So, dealers, customers, distributors, suppliers, and logistics providers can get up and running quickly. Companies can then leverage this digital community to synchronize and optimize their entire supply and demand network in real time based on a single shared version of the truth.

There’s a lot more to the Digital Supply Chain Network. If you’re interested in learning more about what it can do for automotive supply chains, I encourage you to watch the video: How to Digitize, Optimize, and Automate Complex Automotive & Industrial Supply Chains.

Recommended Posts

- What is on the Horizon for Supply Chain Management?

- What Constitutes a True Network?

- Real-World Supply Chain Robotics

- Supply Chain Trends to Watch

- Fielding Software to Defense: A Journey of Ineffectiveness, Inefficiency, and Frustration

- So, You Want Supply Chain Visibility…Why? - November 3, 2023

- Why It is a Critical Time for Automotive Companies - December 20, 2021

- Video: A Guide to Supply Chain Control Towers - September 27, 2018