Every merchant dreams of being able to sell their products quickly. However, sales alone aren’t enough to grow your business – let alone keep it afloat.

To keep your business going, it needs to be profitable. That means you must see a sufficient return on your inventory investment. In other words, you need to make more money selling your inventory than you spent to acquire, store, and fulfill orders with it.

That’s why you need to closely measure metrics such as gross margin return on investment (GMROI). By calculating and tracking your GMROI, you can make more informed decisions on pricing, budgeting, and inventory spending, so that your business can not only survive, but thrive.

In this post, we’ll cover what GMROI is and why it’s important for your retail inventory management. We also walk through an example GMROI calculation, and share some actionable tips for improving your own brand’s GMROI.

What does gross margin return on investment mean?

Gross margin return on investment, or GMROI, is a measure of inventory profitability in the retail industry. Specifically, GMROI measures how much profit you generate from every dollar you invest in your inventory purchases.

This metric doesn’t just account for the cost of buying inventory. It also factors in other expenses involved in holding, maintaining, and preparing inventory for sale, such as inventory storage, transportation, labor, and marketing.

Because GMROI takes all expenses related to inventory into account, it can provide ecommerce retailers with a realistic and holistic understanding of their business profitability.

GMROI formula and calculation (with example)

The formula for calculating GRMOI is:

GMROI = Gross profit/Average inventory cost

As you can see, there are two critical metrics needed to make your calculation. These two metrics can be calculated using their respective formulae.

Gross profit

Gross profit (also called gross margin) is how much profit you were able to generate while accounting for variable costs such as labor and supplies. The following formula is used for calculating gross profit:

Gross profit = Revenue – Cost of goods sold (COGS)

Average inventory cost

Average inventory cost refers to the monetary worth of your inventory over a specific time period. This can be calculated using the following formula:

Average inventory cost = (Current inventory + Previous inventory)/Number of periods

If you need to calculate the average inventory cost for the entire year, you’ll need to find the sum of the beginning inventory for each month of the year and the ending inventory cost for the last month of the year. This will then be divided by 13.

Average inventory cost for a year = (Sum of beginning inventory for every month + Ending inventory cost for the last month)/13

Example

Let’s walk through an example using these formulas.

Say a shoe store needs to calculate their GMROI for a given year. The brand does some digging, and finds the following information:

- Annual revenue – $300,000

- COGS – $45,000

The brand also finds the beginning inventory value for each month of the year, as well as the ending inventory for the last month of the year:

| Month | Beginning inventory cost |

| January | $100,000 |

| February | $120,000 |

| March | $113,000 |

| April | $101,000 |

| May | $118,000 |

| June | $130,000 |

| July | $140,000 |

| August | $125,000 |

| September | $132,000 |

| October | $120,000 |

| November | $130,000 |

| December | $145,000 |

| December – Ending inventory cost | $90,000 |

Using this information, the brand can now calculate gross profit for the year:

Gross profit = Revenue – Cost of goods sold (COGS)

Gross profit = $300,000 – $45,000

Gross profit = $255,000

And average inventory cost for the year:

Average inventory cost = (Sum of beginning inventory for every month + Ending inventory cost for the last month)/13

Average inventory cost = ($1,47,4000 + $90,000)/13

Average inventory cost = $106,461.50

Now that the brand has these two figures, it can plug them into the GMROI formula to calculate their GMROI for the year:

GMROI = Gross profit/Average inventory cost

GMROI = $255,000/$106,461.50

GMROI = $2.40

In other words, for every dollar the brand invests in its inventory, the shoe store makes a profit of $2.40.

Interpreting your GMROI numbers

So what does that result mean? Is $2.40 a good result, or a bad one?

Generally speaking, if your GMROI is more than one, it indicates that your business is profitable. However, it’s also important to consider any industry-specific GMROI benchmarks to make sure that your business is keeping up with the competition.

According to GMROI trends, in 2021, shoe stores were making $2.16 for every dollar spent. So with a GMROI of $2.40 in 2021, the shoe store is in a good position for profitability when compared to its competition.

On the other hand, if the store were in another line of business, like pet supplies, the same GMROI of $2.40 puts it far behind the competition, as the GMROI benchmark in this industry for 2021 is $3.90.

GMROI’s importance for retail inventory management

Your brand’s GMROI is one of the most important supply chain KPIs to track, as it provides you with valuable insight into your profitability. You can then use this insight to accomplish several crucial inventory functions.

Balance inventory levels and profitability

Your GMROI gives you an accurate understanding of your inventory purchases in relation to your business profitability.

For example, a low GMROI may be an indication that you are spending too much on inventory by constantly overstocking (which increases inventory holding and inventory procurement costs). Alternatively, it may indicate that you’re not stocking up fast enough, and are losing sales to stockouts (since you can’t sell inventory you don’t have).

As such, understanding your GMROI helps you understand how to balance your inventory levels and boost profitability accordingly. Constant monitoring your GMROI allows you to reorder inventory strategically and maintain optimal inventory levels to maximize your ROI.

Improve inventory efficiency

Retail owners can also use GMROI at a SKU level to assess the efficiency of each product. By calculating the gross profit and average inventory cost of each SKU, you can achieve SKU-specific inventory analytics that help you identify which products are performing well and which ones are slow to sell.

Make more strategic inventory decisions

With the inventory insights that GMROI can provide, you can make more informed decisions to optimize your inventory strategy for greater profits.

This may involve ramping up production on high-selling SKUs or adjusting your pricing strategies to slash prices on items that are slow to sell, so that you can keep holding costs and inventory turnover in check.

Similarly, your GMROI can help you determine when it’s time to perform SKU rationalization to determine whether certain SKUs should be discontinued altogether. This may involve discontinuing high-profit products that don’t sell quickly.

“ShipBob finally gave us the visibility and analytics we were looking for. Through the dashboard, we get real-time insight into how much inventory to allocate to a specific warehouse, our current on-hand inventory levels, and how long each SKU is going to last by location. ShipBob provides a lot of distribution metrics, and everything presented is useful.”

Mithu Kina, Co-Founder and CEO of Baby Doppler

Practical tips for improving GMROI

Simply put, improving your GMROI requires spending less and (ideally) earning more on inventory, so that your profit margin is higher. Here are some actionable tips that ecommerce brands and retail businesses can use to minimize inventory costs and maximize their GMROI.

Optimize your pricing strategies

When you’re looking to bring in more profit from the sale of your inventory, your first instinct may be to raise your prices. However, higher prices can sometimes discourage customers from purchasing, which could result in deadstock that’s taking up valuable space. In that case, you are not only paying to store those slow-selling items, but you’re also hurting your GMROI in the long run.

That said, it’s important to strategically review your overall pricing structure, and tailor it carefully. This could sometimes mean discounting prices or running a sale on certain items to sell off excess stock (rather than letting it sit in your warehouse). While you will not see as much revenue from those sales, you may save money in the long run by avoiding continuously high holding costs.

Alternatively, consider marginally increasing the prices of products that are selling really well or products with a higher perceived value. Even if some customers are discouraged, you may find that customer loyalty overrides a slight increase in price – especially if your post-purchase experience is very good.

Pinpoint areas for cost reduction

No matter what, to get a better GMROI, you’ll need to reduce your overall spending on inventory. But this doesn’t just mean spending less on inventory acquisition; rather, it includes cutting costs within:

- Procurement (such as raw material and supplier costs)

- Transportation (such as freight, middle mile, and last-mile shipping costs)

- Inventory management (such as software subscription costs)

- Inventory storage (such as real estate or rent, insurance, utilities, and other warehousing costs)

- Order fulfillment (such as the costs of packaging materials, picking equipment, and manual labor)

Consider auditing your supply chain for both cost and efficiency to determine which functions or activities are your biggest cost centers. Optimizing these areas will not only achieve cost-savings, but may also help your operations run better overall.

“Our 3PLs before ShipBob were a total black box when it came to pricing — we’d just get one invoice with no line items, which made it impossible to work out what was what.

With ShipBob, it’s very transparent billing and pricing, and now we know exactly what we’re being charged. We often look at the analytics and finance tabs in the ShipBob dashboard to get a gauge on where spend is going each month and where we can optimize.”

Jonathan Byrt, Director & Co-founder at memobottle

Offload deadstock

Deadstock collects dust on your shelves and eats away at your profit margins, so it’s important to offload it as quickly as possible.

But rather than simply throwing it away, there are ways to put deadstock to good use – or at least recoup some of your investment.

Some of the most popular strategies include:

- Holding clearance or flash sales with majorly discounted prices on deadstock items

- Including deadstock items as a free gift in orders

- Bundling deadstock items with fast-moving SKUs

- Passing or selling deadstock items to a partner business

- Donating items to charity (and claiming an inventory write-off for tax purposes)

Improve demand forecasting

You can avoid deadstock in the first place by improving your demand forecasting. Accurate demand forecasting helps you order just the right amount of inventory to meet demand, so your brand keeps the optimal levels of inventory, and doesn’t overspend on (or inflate storage costs for) inventory it doesn’t need.

Dive deep into your sales and inventory analytics, and make sure to account for seasonal buying patterns and market trends. Based on this, you can get an accurate idea of your true demand, and plan your inventory replenishment strategy accordingly.

An inventory management solutions will record and present this data for you. Some even allow you to set up reorder point notifications, so that you can always know when a SKU is running low and can replenish it at the just right time.

Partner with a professional to optimize inventory operations

Whether you’re an established brand with warehouses full of inventory or a growing brand operating out of a basement, finding ways to reduce inventory costs can be challenging. That’s why many brands find it easier – and more cost-effective – to pass along functions like inventory storage and order fulfillment to the experts.

Professional logistics partners like ShipBob already have infrastructure, technology, and best practices to achieve inventory cost savings at scale. Brands can leverage these resources to lower inventory costs, but also boost order accuracy and fulfillment efficiency while saving valuable time and effort.

GMROI case study: Semaine Health saves $2/order with 99.95% order accuracy

Brands like Semaine Health have been able to achieve lower margins and improve their bottom line by leveraging ShipBob’s inventory management and fulfillment solutions.

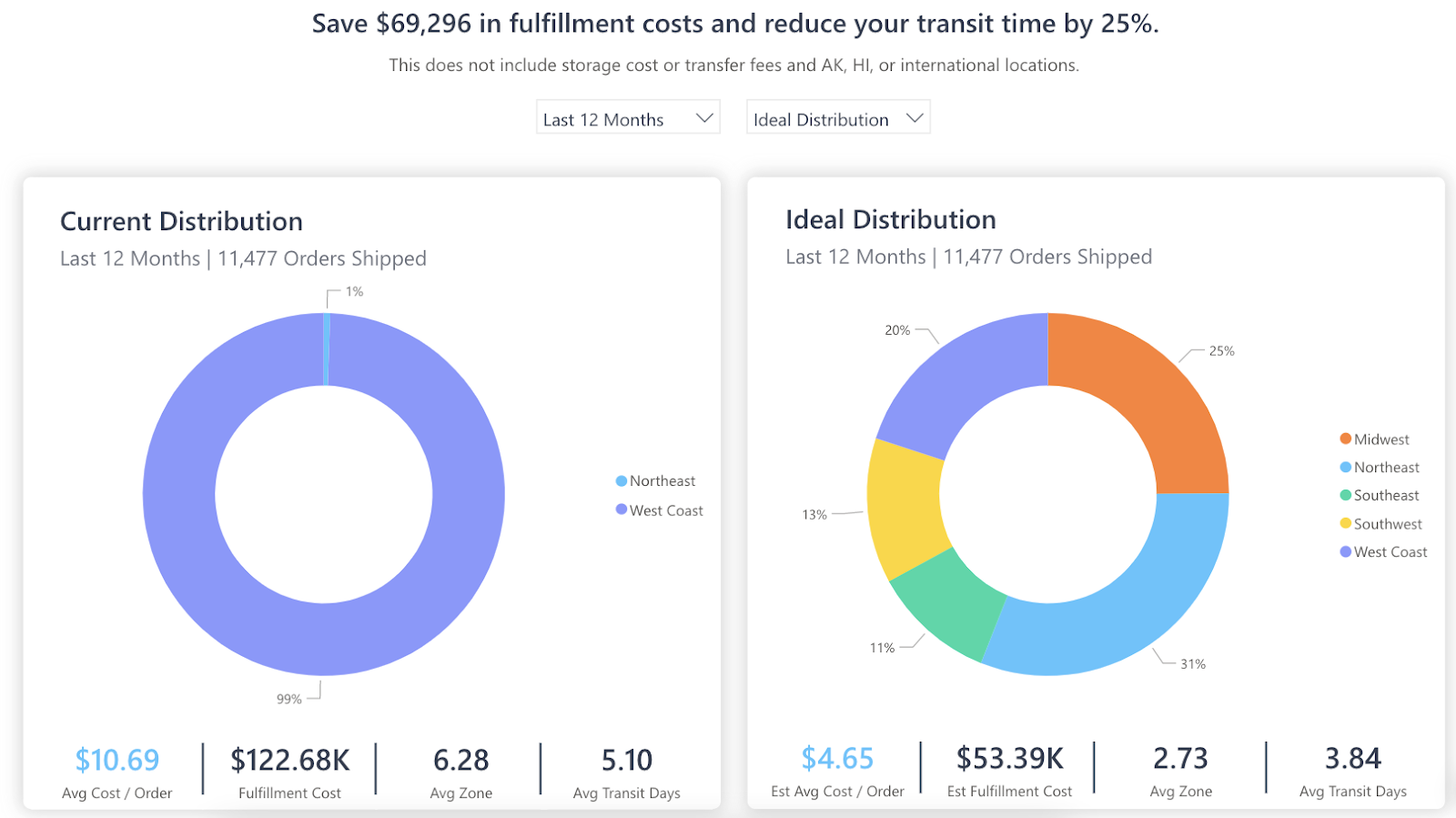

With their previous 3PL, Semaine Health was experiencing a lot of issues that were racking up costs. Not only was the provider consistently making expensive picking and packing errors, but shipping from just one fulfillment center resulted in high shipping costs and long transit times.

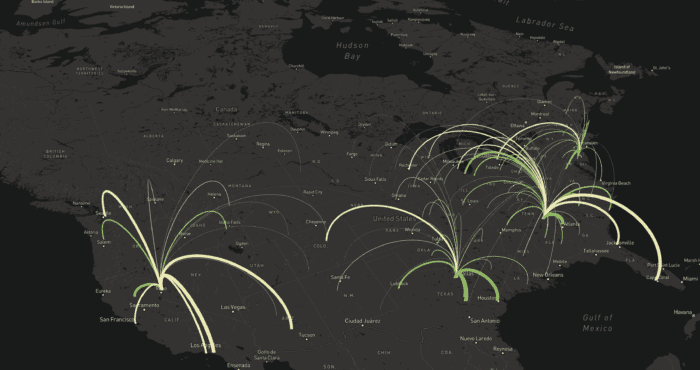

When the brand outsourced fulfillment to ShipBob, they were able to strategically allocate inventory across four fulfillment centers in the U.S. through the Inventory Placement Program. This enabled them to cut their average shipping time by a third, from 5.2 days to just 3.6 days.

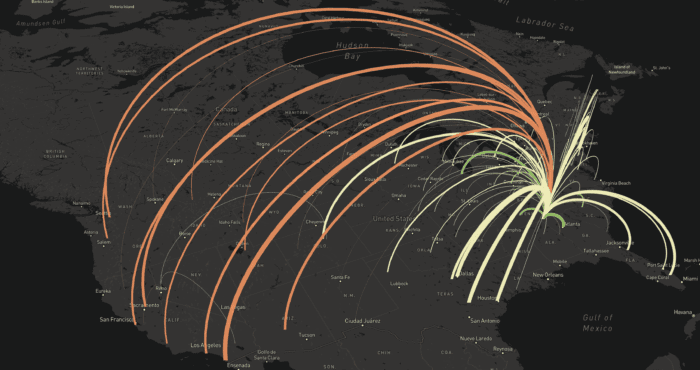

Green = Zones 1-3, Yellow = Zones 4-6, Orange = 7-8

Moreover, they saw a significant reduction in fulfillment costs, saving $2.16 per order compared to their previous 3PL. There was also a 10x reduction in error rate, with an order accuracy rate of 99.95%. This meant that they were no longer wasting money on shipping out the wrong orders and having to pay for return shipments. With all these factors combined, they were able to spend less and boost their profit margins.

“We quadrupled our order volume this year, and because our fulfillment and shipping costs have gotten so much cheaper, we’ve been able to support that scale.”

Matt Crane, Co-Founder and Chief Science Officer at Semaine Health

ShipBob’s unique approach to boosting ecommerce GMROI

It’s incredibly important for ecommerce brands to have the data visibility to measure GMROI, and to constantly be optimizing their inventory management for profitability. ShipBob offers powerful fulfillment solutions and industry-leading inventory management software to help you do both.

Real-time inventory management

ShipBob’s dashboard delivers real-time inventory visibility so you can monitor inventory levels and track location-specific inventory data at all times. This means that you know exactly how much inventory you’re receiving, how much you have available for sale, how many units are getting ready for shipping, and more.

With this level of visibility, you can make informed decisions more quickly and restock accordingly. You have the insights you need to avoid accidentally running out of stock or stocking up on too much inventory that can eat away at your bottom line.

Distributed inventory

With dozens of fulfillment centers across the US and around the world, ShipBob enables brands to allocate and distribute their inventory across multiple locations. This means you get to use fulfillment centers that are closer to your customers, meaning orders can get shipped out from the nearest fulfillment center. That way, you spend less on shipping, which significantly brings down your inventory costs and improves your GMROI.

Merchants can leverage ShipBob’s Ideal Inventory Distribution tool to calculate the most optimal stock allocation based on historical order data. From there, ShipBob can even handle physical distribution for you through the Inventory Placement Program, saving you time, effort, and money.

Analytics and reporting

ShipBob’s cloud-based platform automatically tracks key inventory analytics for you, and presents them in a single, intuitive dashboard. Through the dashboard, you can monitor inventory KPIs that directly impact your GMROI, like:

- Average storage cost per unit

- Average fulfillment cost

- Average shipping cost

- Average days in transit

- Inventory on-hand

- Individual SKU performance

Using these up-to-date metrics, you can glean crucial insights into which SKUs are your best and worst performers, which areas of your inventory operations are ripe for cost-cutting, and more.

Demand forecasting

Brands can leverage Shipbob’s comprehensive analytics to generate more accurate demand forecasts. By predicting your inventory needs based on historical sales data, inventory performance, seasonal demand changes, and market trends that ShipBob’s data tracks and reveals, you can avoid overstocking on slow-selling items while procuring more high-performing SKUs.

Additionally, you can use these predictions to strategically price your products. For example, if you predict high demand for certain items, you could look for ways to increase prices and raise your profits, which will improve your GMROI.

Order management

ShipBob’s proprietary software provides you with robust order management capabilities to streamline your operations and reduce your overall inventory costs. With automatic order processing, you can effectively handle high order volumes with minimal mistakes. Reducing your error rates means that you’re spending less on misshipments and returns, which eventually contribute to a positive GMROI.

Returns management

With higher fulfillment accuracy rates, ShipBob helps you to effectively reduce your ecommerce returns — and with quick shipping, we’ll help you make the returns you do process painless.

ShipBob will handle your returns for you, and you can easily sort returned items based on whether to restock or discard them instead of getting rid of every single return. This helps you to get more use out of the inventory that you’d initially purchased, improving your GMROI.

Additionally, ShipBob’s software integrates with leading returns management platforms so you can streamline the process and get more out of your inventory spending.

To learn more about how ShipBob can help you boost your GMROI, click the button below to connect with a fulfillment expert.

Gross margin return on investment FAQs

Below are answers to the most commonly asked questions about GMROI.

What is considered a good GMROI for ecommerce?

Ecommerce businesses should always have a GMROI of more than $1, which means that you’re making a profit off your inventory. However, the ideal GMROI also depends on industry-specific benchmarks as some industries may see higher GMROI than others or vice versa.

Can ShipBob help improve my GMROI?

Yes. ShipBob can help you improve your GMROI by helping you optimize for inventory cost, and providing you real-time inventory data and analytics that enable you to make more strategic procurement, allocation, and pricing decisions.

How often should I analyze GMROI?

Although GMROI can be tracked annually, analyzing it on a monthly basis may be required for certain products, such as those with a shorter shelf life.

How do seasonal variations affect GMROI calculations?

Seasonal variations may result in changes in demand. Sudden surges or droughts in demand can affect total sales and inventory turnover, and subsequently impact your GMROI calculations.