Inventory is a major current asset in business and should be maintained efficiently to avoid excess stock and unnecessary inventory-carrying costs.

In this blog, you will learn:

- Challenges manufacturers face in maintaining accurate and visible inventory

- How inventory management benefits your manufacturing business

- What the role of ERP is in inventory management

- How an ERP system can improve inventory accuracy

- How manufacturers can achieve inventory visibility with ERP

- Conclusion

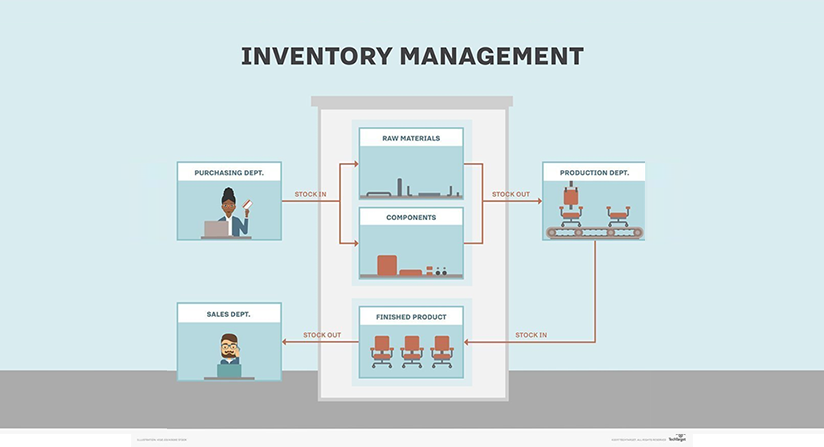

Inventory management supervises the flow of materials from the production point to warehouses, and from there to the end of the sale. Inventory management keeps detailed track of every new and returned product as it is procured or left from a warehouse or point of sale. Inventory visibility, accuracy, control, and optimization are a few terms associated with inventory management. In this blog, we will learn about the basics of inventory management and its related disciplines. But first, let us see what challenges manufacturers face in maintaining accurate and visible inventory.

Challenges manufacturers face in maintaining accurate and visible inventory

1. Stock out and overstocking

Striking the right balance between meeting customer demands promptly and avoiding overstocking or stockouts is a perpetual challenge for manufacturers. Maintaining surplus stock can incur additional costs in terms of labor and utilities. The more stock you have, the more security measures are needed. Therefore, it is crucial to keep the inventory at the lowest possible levels, a strategy that not only reduces costs but also enhances operational efficiency and customer satisfaction.

2. Lack of real-time visibility

Manual tracking can be time-consuming and prone to errors, leading to inefficiencies in inventory management. Today’s workforce requires modern, real-time software that empowers them to manage inventory counts and warehouse activities on the go. This frees up their time to focus on higher-level manufacturing tasks, enabling them to make more informed business decisions and contribute to the overall efficiency of the operation.

3. Inaccurate demand forecasting

When you can’t forecast customer demand, you could end up with surplus inventory, which, as mentioned, costs your business money. Or, you could have too little inventory, which could cause your customers to go elsewhere. Without accurate forecasting, you are prone to extremes in supply purchases, affecting supplier relationships. You can also end up spending more on rush orders.

4. Poor supplier relationships

Supplier relationships are necessary for maintaining an efficient supply chain. Late deliveries, unreliable suppliers, and other issues can disrupt the flow of goods, which might lead to business loss. Regular communication and monitoring of supplier performance can help mitigate potential problems.

Inventory is considered one of the top four common problems in the manufacturing industry.

How does inventory management benefit your manufacturing business?

Manufacturers need a sophisticated inventory management system to collect, process, manage, and report all data. The goal of the inventory management system is to assist warehouse managers in tracking their stock levels and allow them to have complete transparency in their supply chain to monitor the flow of goods. Below are the benefits of inventory management software:

- Better inventory accuracy: An inventory management system allows you to know the correct quantity of stock so that you can meet the demand with the right amount of inventory.

- Cost savings: An inventory management system ensures limited handling and transportation fees, which reduces inventory carrying costs. Also, fewer inventory items mean a lower risk of theft and/or loss from natural disasters.

- Increased profit: When you have deep insight into the demand and availability of goods, manufacturers can see higher inventory turnovers, which leads to a better business bottom line.

- Improved customer experience: With adequate stock, customers get their orders on time, ultimately leading to better customer satisfaction.

- Better cash flow: Cash is spent on inventory that sells, so money is constantly rotating in the business.

Improve inventory management for your manufacturing business by learning about best practices and OptiProERP’s leading manufacturing solution.

What is the role of ERP in inventory management?

Managing inventory with a comprehensive Enterprise Resource Planning (ERP) solution is a prerequisite to proper inventory management. ERP efficiently manages many business functions, including planning, organizing, coordinating, directing, and allocating resources, as well as facilitating paperless transactions and scanning barcodes. An ERP system offers a streamlined solution to your business needs by providing inventory information quickly, efficiently, and accurately.

ERP is a business management suite with multiple modules, including inventory management. From providing end-to-end visibility into stock, to optimizing inventory levels, streamlining operations, and supporting data-driven decision-making, ERP manages all aspects of inventory. ERP inventory management software gives you the insight needed to make better, timelier business decisions.

How can an ERP system improve inventory accuracy?

Before understanding how ERP improves inventory accuracy, let’s understand what inventory accuracy means. Inventory accuracy ensures that the right stock balance is maintained in your warehouses. To ensure inventory accuracy, a cycle count is needed. A cycle count is an inventory auditing procedure that counts a small subset of inventory in a specific location on a particular day. Below is how an ERP system improves inventory accuracy:

1. Maintain an efficient and well-defined warehouse

Plan and strategize appropriately before procuring your warehouse’s raw materials or other goods. Ensure you maintain well-organized bins or shelves to locate inventory items whenever required. Every space in the warehouse needs to be maintained and optimized with utmost accuracy and mindfulness. An ERP system with an inventory management system automates the checking of purchase orders, receipts, issues, and inventory transfers. It lets the warehouse manager accomplish these tasks in a streamlined way.

2. View a bigger picture of your organization

When an inventory issue arises, warehouse managers should be proactive in handling it. An ERP system is pre-built with automated solutions that are focused on streamlining warehouse activities – warehouse transfer, inbound and outbound transfer, barcode scanning, label printing, and much more.

This helps you plan for materials that must be procured, determine which payments to make, which vendors to contact, where to stock items, and more. ERP software lets you manage sales, purchasing, quality checks, lot tracking, cycle counts, inventory operations, finances, accounting, etc. It helps eliminate errors and work delays, encourages planning, reporting, and forecasting, and allows employees to work efficiently.

3. Increased customer satisfaction

Accurate information about inbound and outbound shipments, item locations, and product pricing eliminates product shortages and means that your customers will receive their orders on time. With ERP software, you can manage customer calls, queries, and the entire customer lifecycle. ERP improves employee and customer satisfaction by providing:

- Streamlined shipping operations

- Improved supplier relationships

- A better user experience

- An equilibrium between supply and demand

- Less rework and data redundancy

- Removal of manual processes

- Improved quality of inventory items

ERP systems include Quality Management functionality. It ensures that items stored in the warehouse are ready to be used in production and aren’t damaged. This focuses on lot traceability, managing test processes, and using quarantine orders to set aside needed items. An ERP solution ensures that managers make timely decisions to control compliance and predictability. Businesses can plan for single-level or multi-level sampling and easily track batch and serial numbers to support quality control operations.

ERP lets you plan an inventory roadmap with MRP, MPS, and cycle counting

ERP encompasses modules such as Material Requirements Planning (MRP) and a Master Production Schedule (MPS). MRP ensures that the warehouse is stocked with the proper inventory for production to avoid customer dissatisfaction. MRP facilitates planning for multi-level processes – it allows you to track inventory, specify timelines, manage data sources, and adapt to changing demand. On the other hand, MPS manages lead times, plans for finished goods, ensures allocation of resources, and more.

How can manufacturers achieve inventory visibility with ERP?

Inventory visibility lets you check how much inventory is available, at what location, and at any time. Whether in transit, at the warehouse, or at distribution centers, you should know inventory levels at all locations.ERP helps improve inventory visibility in your supply chain with the following:

- Automated sales order entry – ensures that sales orders are linked to real-time inventory data.

- Enhanced inventory tracking – lets you track when inventory is procured, moved, or sent out of the warehouse.

- Courier/freight automation – integrates your technology with courier companies or freight specialists.

- Better integration—Inventory, Finance, Sales, Procurement, Production—every department is integrated for greater insight.

- MRP automation – receive detailed information about product requirements. Order recommendations are designed for timely delivery.

- Predictive forecasting – encourages stock visibility and lets you predict stock levels to meet customer demand .

ERP eliminates the need for manual scheduling and promotes a just-in-time (JIT) inventory strategy. Materials are ordered and received to meet production requirements, saving inventory overhead expenses and increasing efficiency. With ERP, you get insight into point-of-sale online transactions, shipping data, and procurement and production data, all on a single screen.This enables data-led decision-making, which nurtures relationships with customers and vendors.

Apart from these benefits, using ERP for inventory management also comes with benefits such as delivering orders on time, which leads to customer satisfaction, better cash flow, and cost reduction.

Conclusion

ERP systems are critical in improving inventory accuracy, visibility, and optimization by centralizing data management, providing real-time tracking, facilitating demand forecasting, enhancing supplier collaboration, optimizing warehouse operations, and enabling data-driven decision-making.

Follow Us