Table of Contents

** Minutes

What is the fill rate formula?

Maximize your fill rate with ShipBob

Over the last few years, customer expectations have sky rocketed.

In a world where customers expect to get their orders fast, an efficient fulfillment process is vital for the success of any ecommerce business. As a growing ecommerce business, you can’t afford to have delivery delays resulting from backorders and stockouts.

As a result, the order filling process should be closely monitored and effectively optimized to improve fulfillment and delivery speeds. This is why fill rate is an important metric that ecommerce businesses should track.

What is fill rate?

Fill rate, also called order fulfillment rate, is the percentage of orders that you can ship from your available stock without any lost sales, backorders, or stockouts. It’s a good reflection of your ability to meet customer demand and the overall effectiveness of your ecommerce operations. It also helps you gauge the demand for various SKUs in your inventory and plan your procurement accordingly.

Types of fill rate

Although people generally refer to order fill rate when they talk about “fill rate,” the metric is also used in different stages in order fulfillment process. The different types of fill rate are:

Order fill rate

Order fill rate is a measure of how many orders you managed to fulfill completely without any backorders or stockouts.

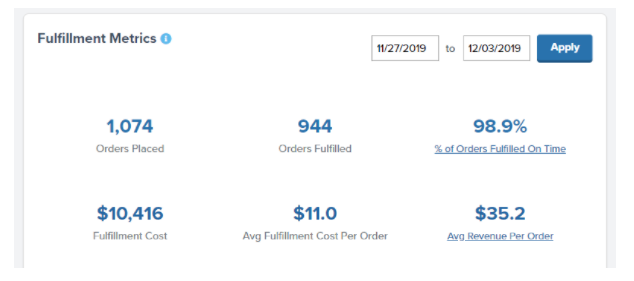

ShipBob maintains a solid track record in fulfilling orders, helping brands achieve a near-perfect order fill rate.

Line fill rate

Line fill rate refers to the percentage of line items that you managed to fill completely out of all the order lines that need to be filled.

Case fill rate

Typically used by wholesalers and distributors, case fill rate is the percentage of product cases that they manage to ship out initially out of all the product cases that were ordered.

Warehouse fill rate

Used for measuring the efficiency of warehousing operations, this metric follows the same concept as order fill rate. Warehouse fill rate measures the percentage of orders that a warehouse is able to fulfill and ship from all the customer orders.

ShipBob continuously maintains a high warehouse fill rate with automated order processing and efficient picking and packing processes.

Vendor fill rate

A useful metric for assessing vendor performance, vendor fill rate is the percentage of vendors who were able to complete order shipments.

What is the fill rate formula?

The fill rate formula is pretty straightforward. You just need to divide the number of orders that were shipped by the total number of orders placed and multiply by 100. That means:

Fill Rate = (Total Orders Shipped / Total Orders Placed) x 100

Fill rate calculation example

You can calculate fill rate by counting the number of orders that you were able to fulfill at one time. Then divide the number by the total number of orders you received and multiply the sum by 100.

For example, let’s say you received 60 orders but were only able to ship out 45, your fill rate will be as follows:

Fill Rate = (45/60) x 100 = 75%

Automated tools like the ShipBob Analytics dashboard makes the job easier by automatically recording the number of orders that were placed and fulfilled as well as orders that are still processing. This way you can quickly calculate your order fill rate.

Why calculate fill rate?

So now that you know how to calculate fill rate, why should you?

Calculating your fill rate is an effective way to gauge other aspects of your fulfillment process and identify opportunities for improvement. Your fill rate may be impacted by a number of factors.

For example, issues with order accuracy could result in extra time spent on recounting inventory, putting items back on the shelf, and repacking items. This means you’re able to fill fewer orders and the fulfillment process is significantly delayed. So a low fill rate may be reason to take a closer look at different steps in your fulfillment process to see what’s causing delays and inefficiencies.

Additionally, your fill rate can help you better understand your inventory management process. If you’re consistently seeing low fill rates due to stockouts, you may need to review your reorder points, or recalculate with the reorder point formula, so you can restock inventory at the right time. Or in some cases, you may even need to look for alternative suppliers.

Calculating your fill rate is also an effective way to understand customer demand. This can help you plan your procurement more accurately to maintain optimal stock levels and ensure that you can meet changing demand.

What is a good fill rate?

To achieve a perfect order rate, your fill rate should be as close to 100% as possible. This rate would indicate that you’re fulfilling all the orders placed without encountering stockouts or backorders. However, this is virtually impossible due to the many factors that can play a part in your filling process.

On average, companies typically maintain a fill rate of about 85%-95%. But ideally, you should strive for a fill rate between 97% and 99%. A fulfillment partner like ShipBob can help you achieve these high numbers using a distributed fulfillment network and robust automation tools. For example, ShipBob helped BAKblade to ship out 20,000-30,000 units in a short amount of time.

Maximize your fill rate with ShipBob

If you’re looking to streamline your fulfillment operations, boost efficiency, and improve fill rate, leveraging with a partner like ShipBob can help you reach your goals, no matter if you’re outsourcing fulfillment or using our warehouse management system (WMS) for in-house fulfillment.

Unlock seamless ecommerce growth

The fastest way to improve your order fill rate is by partnering with a tech-enabled fulfillment partner like ShipBob. With powerful proprietary software that integrates with your ecommerce store, ShipBob lets you automate most of your ecommerce fulfillment processes while giving you better visibility into your inventory management and warehouse operations.

ShipBob automatically processes orders so they’re quickly sent to the fulfillment queue, where items are picked, packed, and ready for shipment in a short amount of time.

Moreover, it eliminates the need for manual entries, which minimizes the risk of mistakes and increases order accuracy. All of these factors significantly speed up the order filling process and enable you to fulfill larger amounts of orders.

Leveraging ShipBob’s fulfillment platform, you can rest assured that, regardless of scale, fill rate won’t be impacted and orders will be shipped to customers on time and in full.

Custom packaging for a memorable unboxing experience

Using custom packaging and other customized touches doesn’t have to slow down fulfillment and impact your company’s fill rate. ShipBob has a robust Customization Suite that allows you to delight customers with branded packaging, custom gift notes, marketing inserts, kitting, and more.

Boost customer satisfaction and encourage repeat purchases while meeting your fill rate metrics with ShipBob’s Customization Suite.

“If someone is going to treat your products like their own, that’s the most you can hope for in a fulfillment partner. ShipBob does exactly that. The customer experience and brand consistency is really important to us, so to receive that level of support from ShipBob means so much to us.

Our trust in ShipBob goes deep, as we know they will help us maintain our brand image.”

– Stephanie Lee, Co-CEO at PetLab Co.

Strategic inventory placement for cost-efficient shipping

Today more than ever, customers crave fast and cheap shipping. However, for many brands, it can be difficult to compete with the shipping promises of retail giants. To help merchants offer quick, cost-efficient shipping, ShipBob has a program to help brands automatically distribute inventory throughout the fulfillment network so orders are routed from fulfillment centers closest to the customer’s door, resulting in fast shipping.

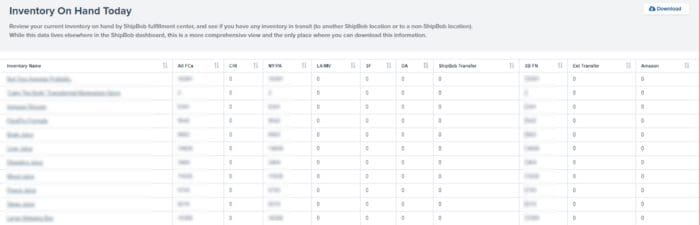

ShipBob’s Inventory Placement (IPP) allows you to seamlessly distribute, manage, and replenish inventory to unlock a supply chain ‘easy button’ for coordinating and monitoring stock levels across locations in the US.

To learn more about ShipBob’s IPP it can help your brand automate inventory placement and minimize shipping times and costs, download this comprehensive guide.

Harness powerful data with ShipBob’s dashboard

The advanced analytics and reporting in ShipBob’s dashboard gives you real-time data at your fingertips, allowing you to make informed decisions about inventory.

By giving you full visibility into your inventory levels, ShipBob’s software lets you know when you’re running low on stock and when you need to reorder. It also lets you set up safety stock and reorder point notifications so you never stockout or miss important inventory dates.

Additionally, ShipBob uses historical sales data to make accurate predictions about future demand. This enables you to have more accurate forecasting and keep optimal inventory levels on hand so you never experience filling delays due to stockouts and backorders.

Customer success story: Bloom Nutrition’s scalable fulfillment journey

ShipBob merchant, Bloom Nutrition, has experienced massive growth thanks to their virality on TikTok, influencer founder, and high-quality product. When they began scaling, they knew they needed a best-in-class- fulfillment partner continue leveling up.

Bloom has embraced ShipBob’s features to leverage the fulfillment platform’s full capacity. The brand leverages branded packaging, marketing inserts, and gift notes to reinforce their image as a premium brand and leverages ShipBob’s IPP to split inventory among fulfillment centers so they can distribute inventory throughout the country to minimize shipping costs.

The result? Bloom has grown to be a 9-figure business in a few short years, with the help of ShipBob.

“When we first partnered with ShipBob, we were fairly small. We had only been in business for a year, were doing less than a million dollars in revenue, and only had a few employees. We couldn’t have imagined that we would get this big – or that our first fulfillment provider would be able to scale with us all the way!

The reality is, when you do what Bloom’s done and scale to millions of orders in just a few years, you outgrow many of your partners. There’s nothing wrong with that – it’s just really uncommon to find a fulfillment provider that can keep meeting your needs as you grow exponentially.

But that’s the niche that ShipBob has created. ShipBob is the rare fulfillment partner that’s built out the services and capabilities successful brands will eventually need, so that as they grow and want to branch out into new geographies, channels, and capabilities, they don’t have to change fulfillment providers.”

– Neil Blewitt, SVP of Operations at Bloom Nutrition

Get started with ShipBob’s WMS

If you’re interested in implementing ShipBob’s WMS solution in your own warehouse to improve fill rate, connect with our team to get started.

Fill rate FAQs

Here are the answers to the top questions about fill rate.

What is the difference between fill rate and inventory turnover?

While fill rate calculates the percentage of orders that were fulfilled at one time, inventory turnover is a metric for measuring the number of times inventory is sold and then replaced during a certain time period.

What is the fill rate formula?

The fill rate formula is: Fill Rate = (Total Orders Shipped / Total Orders Placed) x 100

Can ShipBob help improve fill rate?

ShipBob fulfills orders fast–all orders imported by noon local time are guaranteed to go out on the same day (though many fulfilled after 12 pm local also go out same-day). In addition to scalability, ShipBob also has a high order accuracy rate.

What is the difference between service level and fill rate?

Service level is the percentage of customer orders that a company can satisfy from its inventory without causing delays. It is a measure that determines how well a company is able to meet demand for both delivery time and correct quantity.

Fill rate is the percentage of orders that are fulfilled at one time. It is a measure of the amount of orders actually fulfilled against the total number of orders.

How does fill rate impact customer satisfaction and inventory costs?

Since fill rate measures how quickly orders are fulfilled, it can impact customer satisfaction positively or negatively. If you have a high fill rate, customers will receive their orders faster, resulting in greater satisfaction. If you have a low fill rate, customers will be waiting longer for their orders which can result in a negative customer experience.

Fill rate can also impact inventory costs. A lower fill rate may be a result of poor inventory management which can lead to overstocking or stocking out, both of which can eat into inventory costs. Additionally, if you have a low fill rate, you may be paying more for inventory storage.

Set sail for new horizons

with ShipBob

Order fulfillment services

Warehousing, packing, shipping, tracking, and returns. 2-day shipping. Custom packaging.

Inventory management

Single source of truth across fulfillment centers. Track in real time. Know when to restock.

Omnichannel fulfillment

Integrate with all major ecommerce platforms and marketplaces. Shopify, Amazon, TikTok, and 100+ retailers.