A TIMELINE OF WMS EFFICIENCY IMPROVEMENTS AND ROI ON YOUR INVESTMENT

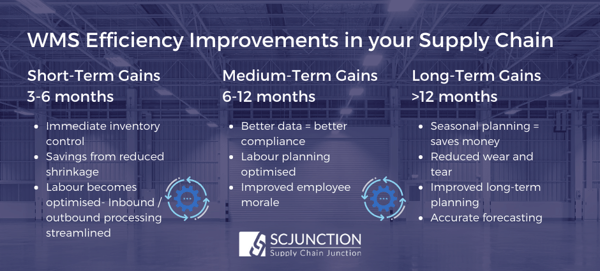

When you go live with a best of breed WMS, you will find your business making gains in multiple areas, which is exactly why you have chosen this solution! With more efficient processes you will soon see a positive impact on your operations and then supply chain, both immediately AND down the line... but when?

Your new WMS implementation project plan has been smoothly designed with the aim of optimising your warehouse and supply chain processes including: accuracy, visibility, productivity, customer service and error reduction. Now you want to measure the impact of the WMS on your supply chain to evaluate the success, and tweak further improvements.

The first step to realising changes is to benchmark your existing KPIs. Monitoring your current warehouse performance will assist you to compare data over time, reduce costs and ensure consistency across your supply chain, driving big changes in behaviours and processes to maximise efficiency. This in turn leads to some very real savings, as well as the ultimate win: happier staff and delighted customers, and delighted customers are not only return customers, but they usually bring friends.

To be objective, there are two massive spheres of improvement: your warehouse, and the ramifications on your supply chain efficiency. Obviously the most immediate return on your WMS implementation will be had "on the ground" in daily operations; the later impacts will be seen depending on those improvements.

The Primary Efficiency Impacts of a WMS:

Your warehouse

1. Real-time access to quality data = increased visibility throughout your supply chain

Management, warehouse, and sales teams get an accurate, real-time picture of various stages of inbound and outbound orders. This allows you to track, report, and optimise your processes on the go.

SHORT TERM (3-6 months)

You can only fix what you can see: visibility means rapid decisions can be made correctively and preemptively to improve business and warehouse functionality.

2. Efficient labour allocation = reduced warehouse labour costs

Managers can obtain comprehensive reports on all activities happening in the warehouse, with the accurate data an KPIs provided allowing a demand forecast to show the labour required, when, where, and for how long. Employee management is simplified, and downtime is reduced.

Kolok, for example, reduced their warehouse floor labour complement by 50%.

MEDIUM TO LONG TERM (6-12+ months)

Labour costs are a massive save, as the workforce becomes targeted and tracked to maximise their hours, improving both business and staff satisfaction.

3. Streamlined warehouse processes = maximum output

The WMS facilitates inventory and resource management efficient outbound order shipping and fulfillment. This goes on to improve your warehouse efficiency, allowing for a smoother operation from inbound to outbound operations.

Warehouse managers can now also track where the goods are, and respond to any arrival delays ahead of time to manage customer / business expectations.

SHORT TERM (3-6 months)

Efficiency means you can do more with less."Within two days [of going live] we were shipping in excess of our store distribution plan."

- Jan Tukker

The Foschini Group

Download the Foschini Case Study

4. Optimised warehouse layout = better time spend

With a WMS helping you to optimise your processes, you can examine your warehouse layout in conjunction with the WMS and improve the ease-of-access to allow for smoother overall warehouse processes.

SHORT TERM (3-6 months)

Less time spent searching means more time is free to pack, ship, fulfill, ensuring bliss for labour and customers alike.

5. Improved inventory and pick accuracy = decreased time between picks

With the simplification of all operations - from inventory control, staff management and space management – your inventory management improves, and your pick accuracy and customer service are optimised to create a faster turnaround in the inventory department.

SHORT TO MEDIUM TERM (3-12months)

Faster picking times mean orders are pushed out faster, and more orders can be fulfilled in the same time. This leads to increased profitability and more customers able to satisfy.

6. Better warehouse flexibility = better responsiveness

Automation and streamlining of processes reduce error rates when dependency on manpower lessens. This reduction in human error and administration time allows a faster, more appropriate response to sudden changes, errors, or upheavals that may occur.

SHORT TO MEDIUM TERM (3-12 months)

Better time management saves man hours of labour costs, administrative costs, and the cost of not pushing out the next order rapidly.

7. Increased safety and security = protected assets

As mentioned in our blog “Warehouse Theft Prevention Tips: How to Spot (And Stop) Light Fingers”, the less accurate your inventory records, the faster your warehouse becomes an easy target.

Knowing exactly what stock you have on hand (and where that stock is located in your warehouse) helps you identify missing stock immediately and ultimately reduces warehouse theft. However, trying to keep track of stock manually often leads to errors - especially if you’re doing infrequent stock takes.

SHORT TERM (3-6 months)

Save on theft, shrinkage, and errors and keep your stock in your warehouse... and in customer's hands.

Remember: if you want to see quicker results, you need to ensure a smooth implementation. To ensure this, you need to have your technological ducks in a row, such as ensuring an excellent implementation team and having superb master data on hand for your service provider.

These impacts all contribute to an optimised warehouse which runs smoothly, has greater quality output, and delivers on KPIs consistently and efficiently.

With the warehouse running at an optimum, the impacts will be visible across your business in your sales capabilities, financial planning accuracy, and customer service.

The Secondary Efficiency Impacts of a WMS:

Your Supply Chain

1. Accurate demand-forecasting

At any point in time, previous data can be recovered and used to help management make strategic decisions which drive business growth. Allow your business to forecast demand, employ the right size labour force for the forecast period, and ensure your suppliers, support teams, and client-facing staff are well-versed in the strategies to accommodate busy periods.

LONG TERM SEASONAL (in 12-month cycles)

Save money with administration costs and avoiding poor decisions from inaccurate data.

2. Improved supplier relationships

By avoiding the last-minute panic that so often plagues manufacturing and production businesses, you will be able to cultivate healthy, long-lasting supplier relationships based on practical and accurate requests, and on-time delivery.

SHORT TO LONG TERM (3-12+ months)

Profits steadily increase as happy customers become return customers.

3. Improved customer service levels

With your suppliers delivering on time, your warehouse working efficiently, and your forecasts up to date and as accurate as possible, you will find more time to pay attention to your customer satisfaction: reduce damage to goods, improve delivery times, and eliminate incorrect picking errors which result in customer complaints.

SHORT TERM (3-6 months)

Fewer errors = fewer associated costs (such as replacements and repeat logistics).

4. The ability to implement an ongoing optimisation strategy

Time is everything in a warehouse: time to examine processes, time to change up your methods, time to train employees, and time to ensure a quality product reaches your customers. Your WMS reduces time spent on inventory control, staff management and space management of goods, so that you can focus your energies on team building, training, and process optimisation.

LONG TERM (12+ months)

Time is money; more time at your disposal means you can redirect it to expansion, marketing, and other energies.

The Ultimate Impact:

Expenditure and Income

The essential outcome of any business change and the implementation of a WMS is simply to reduce overheads, and increase income. To be able to justify your investment, you need to see the ROI.

All of the above impacts serve to reduce your expenditure, whether it be on your labour complement, storage, inventory, poor supplier relationships, or addressing customer complaints.

By becoming more productive, providing excellent service, and allowing the opportunity for expansion, profitability rises.

The typical improvements and savings we see being achieved with a successful WMS implementation include:

- Labour utilisation savings of 10-45%

- Inventory reduction of 5-40%

- Warehouse utilisation increases by 10-40%

- Picker productivity up by 10-50%

- Shrinkage reduced by 50-99+%

- Increase shipping accuracy to 99%

- Increase supplier conformance 99% +

- Customer service 10-50%

- Increased inventory availability 10-50%

The question is not whether you can afford to embrace the next development in WMS excellence: it is whether, in a globally competitive climate, you can afford not to.

Read the Cambridge Case Study for a fuller view on the immediate, mid-term, and long-term benefit of implementing a WMS.

TAGS

- WMS (51)

- Warehouse Best Practice (46)

- Implementing a WMS (29)

- Managing your warehouse (19)

- Omni Channel (18)

- eCommerce (18)

- Blog (16)

- Supply Chain Best Practice (16)

- Mid-Level (8)

- Customer Journey (7)

- Warehouse optimisation (7)

- General Tips (5)

- Industry General (5)

- Information (5)

- Trends (5)

- managing your Supply Chain (5)

- saudi arabia (5)

- smart warehouse (4)

- 3PL (3)

- News (3)

- ERP (2)

- Entry-level (2)

- ROI (2)

- Case Study (1)

- OMS (1)

- Picking (1)

- Press Release (1)

- Solution-Specific (1)

- Transport Management System (1)

Take A Look At The Results Of A Successful WMS Implementation.

See how Tarsus Distribution, in collaboration with SCJ boost overall efficiency by 60%