Are you tired of dealing with excessive inventory levels that eat up your storage space, tie up your capital, and hinder your company’s growth? If so, then it’s time to consider the numerous benefits of reducing inventory. In this article, we’ll explore seven compelling reasons why you should reduce inventory and how it can be a game-changer for your business. From improving cash flow and reducing carrying costs to increasing product turnover and minimizing the risk of obsolescence, there are plenty of advantages to be gained. By implementing effective inventory management and inventory reduction strategies, you can optimize your operations, enhance customer satisfaction, and ultimately boost your bottom line. So, if you’re ready to take control of your inventory and unlock the hidden potential of your business, read on to discover why reducing inventory is a smart move for any organization.

[Read More: 12 Useful Websites to Help You Liquidate Inventory and Make Money]

Inventory Reduction: Why do it?

Inventories are designed to match customer(s) demand. Following the ever-changing nature of businesses, optimal cost control has not always taken the front seat in the priority list. Long ago, companies maintained a firm level of inventory due to low competition from its rivals. Today, the rising growth in any sector has seen more competitors willing to adapt and implement rapid changing features to suit the growing market.

These changes and adaptability demand for products is causing several variations in inventory as well. Your use of inventory should follow suitable plans that keep the business balanced. In some cases, inventory levels can see an increase to save costs, increase profit, and more.

But when should you consider reducing inventory? Try thinking of it this way, if you plan to make big profits, you would need to invest and diversify your portfolio into several sources to improve your chance of success. The same applies to inventory reduction.

According to GT Nexus, an “out-of-stock” situation was experienced by 81% of consumers in the last 12 months. Also, in the global market, a whopping $1.75 trillion loss was recorded by retailers due to inventory mismanagement.

Inventory reduction is performed for several reasons, let us now look into seven such reasons.

Reasons to Reduce Inventory

The following is the list of reasons why we believe you should work towards reducing your inventory:

- Inventory reduction improves corporate profits

- Increased cash flow

- Inventory management improves quality

- Reducing inventory helps in lowering inventory carrying cost

- It improves customer service

- It reduces the risk associated with carrying inventory

- Streamlined operations and increased efficiency

[Read More: Vendor Managed Inventory: A Comprehensive Guide]

Reason # 1: Inventory Reduction Improves Corporate Profits

A Reduce Inventory has extensive implications on business profitability and Return on Investment (ROI). The ensuing lower expense from reducing inventory will deliver more profit. For instance, through the implementation of Electronic Data Interchange (EDI), a business can reduce its needed cycle stock by $5 million. This implementation further lessens the order transmission time without reducing lead time to its final buyers. These benefits are highlighted in the table below (Table 1).

What are the effects to be expected?

First, profitability increases due to reduce inventory in carrying costs. Following an annual increase in inventory carrying cost by 30 per cent, the company X saw a $1.5 million reduction in its inventory carrying costs (30% * $5 million inventory reduction). This approach directly improved the pretax profit at the bottom line by $1.5 million. The pretax profit margin grew from earlier projected 4.0% to 5.5% as the firm increases earnings the same sales dollars. Also, the return on assets rose from 10.0% to 13.8% because the firm could create more returns (profit) with fewer assets.

Table 1: Company X Financial Data for Analysis Purposes

| Before Inventory Reduction | After Inventory Reduction | ||||

| Income Statement ($ millions) | |||||

| Sales | $100.0 | $100.0 | |||

| Cost of goods sold (COGS) | 60.0 | 60.0 | |||

| Gross Margin | 40.0 | 40.0 | |||

| Operating Variable | 18.0 | 16.5 | |||

| Operating Fixed | 18.0 | 18.0 | |||

| Pretax Profit | $ 4.0 | $ 5.5 | |||

| Balance Sheet ($ millions) | |||||

| Current Asset Inventory | $ 14.0 | $ 9.0 | |||

| Other | 8.0 | 8.0 | |||

| Total | 22.0 | 17.0 | |||

| Fixed Assets | 18.0 | 23.0 | |||

| Total Assets | $ 40.0 | $ 40.0 | |||

| Profit Margin | |||||

| Profit/Sales | $4/$100 = 4% | $5.5/$100 = 5.5% | |||

| Return on Assets | |||||

| Profit/Total Assets | $4/$40 = 10% | $5.5/$40 =13.8% | |||

| Inventory Turnover | |||||

| COGS/Inventory | $60/$14 = 4.3 times | $60/$9 = 6.7 times | |||

Second, the inventory turnover grew because average inventory was lower on the same sales dollars. Analysts love such numbers, and in this case, the figures went from 4.3% to 6.7%! The improvement in inventory management plays a crucial role in the firm’s long-term profit growth. Other ratios are expected to benefit from the improvement ratios as well.

Reason # 2: Increased cash flow

One of the most significant benefits of reducing inventory is the improvement in cash flow. When you have excess inventory sitting on your shelves, it ties up your capital that could be used for other critical business activities. By reducing inventory, you can free up valuable working capital that can be reinvested in areas such as research and development, marketing campaigns, or expansion plans. Improved cash flow allows for greater flexibility and enables your business to seize opportunities as they arise.

Furthermore, reducing inventory can help mitigate the risk of stockouts. By having a leaner inventory, you can better forecast demand and ensure that you have enough stock to meet customer needs without overstocking. This reduces the chances of lost sales and the associated costs of rush orders or expedited shipping.

Reason # 3: Inventory Management Improves Quality

Since the use of interchangeable parts and mass production methods, reduce inventory effectively increases the output obtained from raw materials and partially-completed products. Over time, having huge inventories were considered necessary. But times are changing, the use of reduce inventory offers more quality and useful performance metrics.

The use of reduce inventory in production optimizes delays and reduces other associated costs. If your setup costs get spread over the run of a production, using reduce inventory would naturally lead to smaller setup cost.

More extensive inventories were thought to provide safety margins (or similar known philosophies held) such that they would meet any increase in consumer demands. They were also considered to provide a buffer against quality issues. This conventional wisdom and management philosophy carry some level of heavy burden, which is the cost of maintaining the inventory. Someone has to pay for then, and that implies the cost eventually gets passed to the final customer.

The practice of reducing inventory in management is one approach appreciated for improving quality. An expected outcome for low production, especially where the usage of large inventory is involved, is product flow imbalances that leads to bottlenecks and less quality. The usage of useful performance metrics offered by the use of reduce inventory actually reward behavior that tends to enhance your products final quality. Reduce inventory lets you measure production efficiency, utilize and standardize hours produced (mainly for overhead absorption).

Reason # 4: Reduce Inventory Carrying Cost

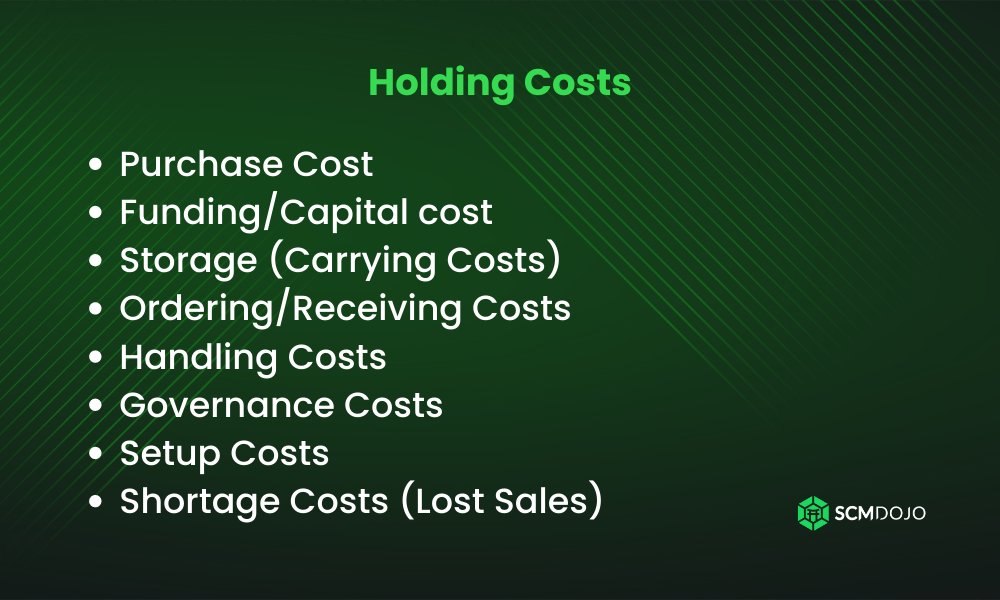

Inventory carrying cost (which usually describes any value acquired by a business for holding inventory over a specified time frame) can include the cost of obsolesce, damage, insurance, relocation, shrinkage, taxes, and warehouse. As far as storing stocks/raw materials remains essential, these costs will directly or indirectly affect your overall annual profit and loss. The best practice today employs the use of reducing inventory to have a precise calculation for inventory carrying cost.

The inventory carrying cost restricts your capital expansion as such money could be put into other investments and projects. Also, the Risk of fluctuations is present as whatever happens to such stocks can no longer be sold at its original purchase value. For instance, if an equipment manufacturing firm stocks various product parts and they no longer become sellable, they could be sold at a massive loss.

In order words, Excess and Obsolete Inventory Is killing your business! With minimal to no real value addition, it is usually advisable to consider the opportunity cost of any inventory. If your calculation shows your company will be losing more at the Risk of cash investment, then there’s a need to reduce inventory or consider other investment prospects.

To reduce inventory carrying cost, the following 9 contributors’ impact (Insurance, Taxes, Plant Warehouse, Inventory Handling Cost, Rented or 3PL Warehouse, cost of obsolescence, Damage cost, shrink cost, capital cost) will require practical reduction. Also, your holding cost, as highlighted below, should be considered as well.

Reason # 5: It Improves Customer Service

The use of reduce inventory can help you get rid of unwanted Excess and Obsolete Inventory as well as let you bring inadequate inventory. Your customer satisfaction plays a crucial role in your business, especially SMEs. If you are continually seeking new methods or ways to improve customer service, and inventory reduction can help you gain the needed knowledge and ideas to satisfy loyal customers with short- and long- term plans.

Although innovation is vital, accomplishing the basics excellently is often disregarded in a bid to enhance customer satisfaction. If your customer finds difficulty in the ordering process, you may want to change that, especially from the inventory. A reduce inventory improves customer services as it let you:

Prevent Understocking – you get first-hand information on how much inventory to incur or reduce the following sampled feedbacks from your customers. By effectively tracking stocks and seasonal demands, a reduce inventory can help you decide quickly without facing so many constraints.

Forecast Seasonal Demand – The customers are always around during seasonal demands. Getting the right stocks using a careful stock control would help you meet needs without any compromise.

Improve Order Fulfilment – Delivering the wrong products can be a stressful experience for both parties depending on the particular inventory. The use of reduce inventory simplifies the fulfilment process and effortlessly improve customer services.

Reduce Lead Times – Lead time is a crucial factor affecting customer satisfaction. Most customers prefer a quick delivery and reliable system for inventories. A reduce inventory keeps you in the loop as you offer products in demand more efficiently.

Reason # 6: It Reduces Risk Associated with Inventory

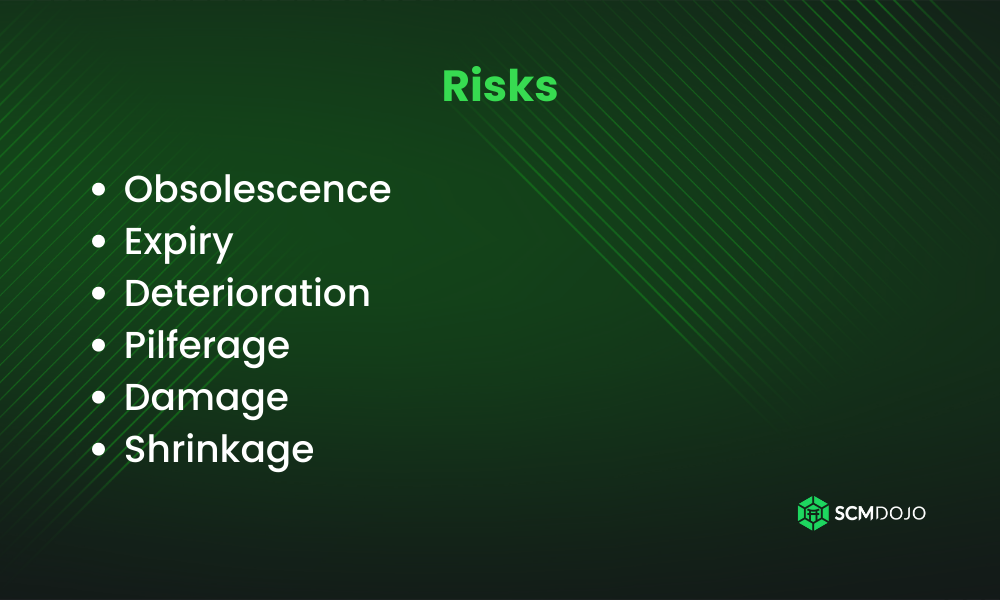

Your inventory remains a high-value asset and frequently characterizes a significant risk. To maintain profitability, reduce inventory becomes crucial. A reduced inventory lets you focus more on essential parts of the business which further mitigate associated risks. The associated Risk in inventory may include Obsolescence, Expiry, Deterioration, Pilferage, Damage, Shrinkage.

Obsolescence – With time, a large number of inventories suffer a decline in value. Tracking your revenue data and regularly reduce inventory through promos, discounts, and other approaches can mitigate associated risks.

Expiry – Having outdated inventories would impact your final profits if you continue to hold and use them. You should employ creative techniques to get them off and receive fresh stocks.

Damage – Identifying frequent causes of damage should be noted and controlled using reduce inventory. You can apply more stringent measures to help employees become better handlers.

Deterioration – limit the number of boxes to be stacked as well as other preventive measures to limit the damage. Putting a strict policy in place may help you reduce your inventory.

Reason # 7: Streamlined Operations and Increased Efficiency

Having a leaner inventory can lead to streamlined operations and increased efficiency. When you have excess inventory, it can lead to inefficiencies in your supply chain, including longer lead times, increased transportation costs, and more complex inventory management processes.

By reducing inventory, you can simplify your supply chain and eliminate unnecessary steps. This can lead to shorter lead times, reduced transportation costs, and improved overall operational efficiency. With a leaner inventory, you can focus on optimizing your processes and ensuring that your resources are being used efficiently, enabling you to improve productivity and reduce waste.

Conclusion

Today, inventory plays a crucial part in the growth of any business. If you have less control over your inventory, your business process is likely to be less optimized, and you may be losing profits. The practice of reducing inventory provides several benefits for your business. Overall, you get a quick turn over for your inventory and better efficiency. Reducing inventory also lets you plan better, so get on board now.

–

About the Author – Dr Muddassir Ahmed

Dr MuddassirAhmed is the Founder & CEO of SCMDOJO. He is a global speaker, vlogger and supply chain industry expert with 17 years of experience in the Manufacturing Industry in the UK, Europe, the Middle East and South East Asia in various Supply Chain leadership roles. Dr. Muddassir has received a PhD in Management Science from Lancaster University Management School. Muddassir is a Six Sigma black belt and founded the leading supply chain platform SCMDOJO to enable supply chain professionals and teams to thrive by providing best-in-class knowledge content, tools and access to experts.

You can follow him on LinkedIn, Facebook, Twitter or Instagram.