Table of Contents

** Minutes

What is inventory segmentation?

Ecommerce businesses: don’t ignore inventory segmentation

Inventory segmentation tips & best practices

How ShipBob utilizes inventory segmentation

The root of many inventory management challenges lies in treating all stock equally—when in reality, each item should be assessed and segmented individually. Treating all stock the same can quickly lead to costly inefficiencies like overstocks and stockouts.

This is where inventory segmentation can help. It’s a strategy that categorizes inventory based on factors like demand patterns, lead time, value, and more.

Although inventory segmentation may not be on the radar of many ecommerce businesses, it’s a key component to achieving an optimized warehouse.

In this article, we’ll guide you through the intricacies of inventory segmentation, exploring its benefits, outlining how it can be implemented, and sharing insights into how ShipBob leverages this strategy to optimize our own fulfillment services.

What is inventory segmentation?

Inventory segmentation is the process of categorizing inventory into manageable segments to optimize everything from storage to order fulfillment. It’s especially crucial in ecommerce, where customer satisfaction relies on speed and accuracy. Inventory segmentation ensures that each product is placed and managed according to specific metrics, creating a streamlined path from shelf to shipment.

Although not as commonplace as broader terms like inventory management, inventory segmentation is a sub-strategy of managing inventory that plays a significant role in improving efficiency and reducing costs.

Ecommerce businesses: don’t ignore inventory segmentation

Let’s face it, planning out your business’s inventory segmentation probably isn’t at the top of your list of to-do’s. However, embracing inventory tools like ABC analysis can transform how you manage your stock, allocate your resources, and satisfy your customers.

Let’s explore a few of the advantages of implementing inventory segmentation as part of an overarching inventory management strategy.

Order fulfillment efficiency

Everyone wants their supply chain management process to be as smooth as possible. Efficient order fulfillment is crucial for seamless warehouse operations and customer satisfaction. Inventory segmentation helps sharpen this path.

By grouping products based on factors like sales velocity, size, and shipping requirements, warehouses can improve picking rates. This inventory optimization leads to faster order processing.

Savings across the board

Inventory segmentation isn’t just about organizing stock; it’s about the intelligent allocation of all resources. When inventory is segmented, businesses can optimize storage space, prioritize resources for items with a high turnover ratio, optimize labor usage, and reduce carrying costs associated with overstocking or obsolescence.

Happy customers

A direct benefit of efficient inventory management is increased customer satisfaction. When customers receive their orders quickly and accurately, trust is built which leads to repeat business.

Inventory classification contributes to greater customer satisfaction by ensuring that popular items are on hand and backorders are minimized (which also helps your fill rate). Having proper stock levels makes sure delivery promises made at checkout are kept.

Growth & profitability

Ultimately, the goal of any ecommerce business is sustainable growth and profitability. Inventory segmentation provides the data-driven insights needed for informed decision-making. By analyzing segmented inventory performance, businesses can identify trends and forecast demand, adjust purchasing decisions, avoid disruptions and set backs like stockouts, and optimize their product offerings to better appeal to customers.

Inventory segmentation tips & best practices

At ShipBob, we’ve seen the power of effective inventory segmentation firsthand. It’s an especially important process for businesses with large inventory investments to master.

Here are some tips and best practices drawn from our experience to help your business implement a solid inventory segmentation strategy.

- Categorize using ABC, XYZ, or ABC+XYZ methodologies: Initiate your segmentation by classifying inventory using ABC segmentation (based on value or importance), XYZ segmentation (based on demand predictability), or a combined ABC+XYZ strategy to prioritize your items effectively.

- Employ inventory tags: Implement the use of electronic or physical tags to identify items by their segment, such as SKUs, QR codes, RFID tags, or color-coded labels for streamlined identification and management.

- Integrate software: Adopt an advanced inventory management software solution capable of managing sophisticated inventory segments, offering real-time data, automated reordering, and actionable insights.

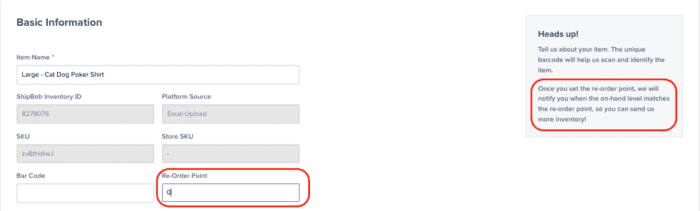

- Establish reorder points for each segment: Define specific reorder points tailored to each inventory category, with higher-priority items having higher thresholds to prevent stockouts. This way, you’ll always have the correct number of items on hand.

- Regularly audit and adjust segments: Stay responsive to market shifts and consumer trends by frequently auditing your inventory categories and adapting as necessary.

- Optimize storage layout: Design your warehouse storage layout to mirror inventory segmentation best practices by placing high-priority and fast-moving items in easily accessible locations.

- Review seasonal and trend data: Leverage seasonality and trend analysis to forecast changes in segment demand, adjust your stock levels, manage procurement, and reorder strategies.

How ShipBob utilizes inventory segmentation

ShipBob partners with thousands of ecommerce companies to help them optimize their fulfillment strategy. Our proprietary technology helps brands achieve efficient inventory segmentation.

We have built a best-in-class warehouse management system (WMS) that is available for brands to leverage. A robust WMS is a key source of data providing insights such as sales velocity, seasonal trends, product lifecycle stages, and customer buying patterns. These metrics are crucial in determining your segmentation approach.

In essence, ShipBob’s inventory segmentation isn’t just about organization—it’s about smart, data-driven decision-making. It’s a critical component of our end-to-end fulfillment solution, designed to help ecommerce businesses of all sizes reduce costs, improve operational efficiency, and deliver an exceptional shopper experience.

3 businesses succeeding with ShipBob’s inventory management

The proof of ShipBob’s inventory management efficiency is reflected in the successes of our clients.

Consider the case of Black Claw LLC. Being able to manage inventory in multiple warehouses through one dashboard saves them both time and headaches.

“Off the bat, I liked that I would be able to control multiple warehouses through one page with ShipBob. With my old 3PL, I could never just open a page and get the info I wanted. I had to click several times, then export it, and try to make sense of it. ShipBob lets you manage your inventory while providing important data in a very digestible way.”

Wes Brown, Head of Operations at Black Claw LLC

Or how about the baby outdoor lifestyle products brand, IZIMNI. Leveraging the efficient inventory segmentation capabilities of ShipBob, IZIMNI is able to seamlessly add marketing insertions to their orders with a click of a button.

“We love ShipBob’s technology. The dashboard is very intuitive. I like that we can create our own rules, such as adding marketing insertions to orders, which makes it super easy.”

The IZIMINI Team

If you’re a brand that’s continuously launching new products, like FLEO Shorts, a fulfillment partner with a strong inventory control and segmentation system is an absolute must.

“We roll out new products and designs on our website 1-3 times a month and send new inventory to ShipBob each week. It’s really easy to create new SKUs and restock existing ones using ShipBob’s technology, which is especially important with high inventory turnover.”

Carl Protsch, Co-Founder of FLEO Shorts

If there’s one thing in common between each of these businesses it’s that having a powerful inventory management system is critically important. Even seemingly little things like determining the correct order quantity, safety stock, or the best methods for stock classification can have a huge impact on your business.

ShipBob is your ideal partner for inventory management

As you’re aware by now, inventory segmentation is much more than just a way to organize products.

As an end-to-end fulfillment partner, ShipBob knows the importance of having a rock-solid inventory management strategy paired with software that’s both intelligent and intuitive. That’s why our technology has a gold-standard inventory management solution that is designed with powerful capabilities meant to streamline your operations.

Real-time inventory tracking

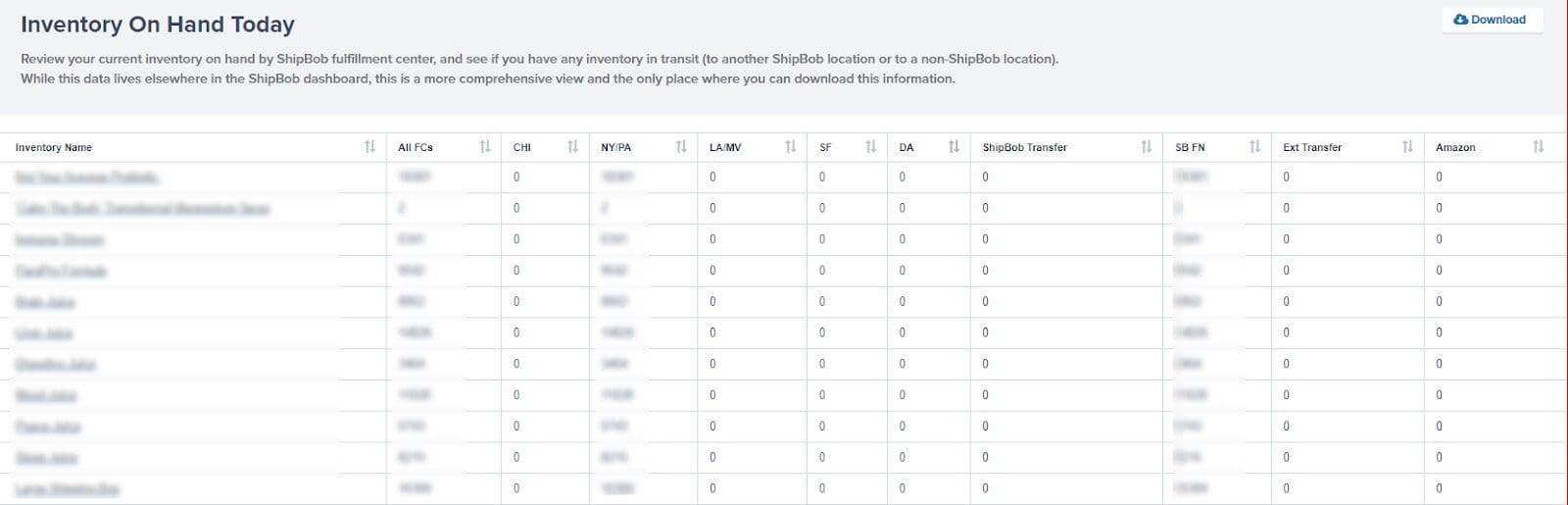

With ShipBob’s real-time inventory tracking, you get a comprehensive and up-to-date snapshot of your products. This tool gives you a bird’s eye view of all your inventory, no matter where it’s stored within ShipBob’s global fulfillment network.

Automated reorder points

Say goodbye to unexpected stock shortages. With ShipBob’s automated reorder points, keeping your inventory levels optimal is more manageable and efficient. This feature allows you to define a specific point for when it’s time to replenish your stock, helping you maintain a steady supply and avoid “out of stock” scenarios.

Multiple distribution points

With ShipBob, your inventory is not just stored — it’s strategically distributed throughout our fulfillment network. By distributing your inventory throughout the US (and the rest of the world), your products are closer to your end customers, which translates to faster delivery times and reduced shipping expenses.

Get started with ShipBob

Want to learn more about how ShipBob can help your business with inventory segmentation? Connect with our team to get started.

Inventory segmentation FAQs

Below are answers to common questions about inventory segmentation.

What is the first step in implementing inventory segmentation?

Conducting a comprehensive inventory audit is the first step in implementing inventory segmentation. This involves taking stock of all inventory items and gathering data on sales history, turnover rates, and product categorization, which will serve as the foundation for creating effective segmentation criteria.

Can small businesses benefit from inventory segmentation?

Yes, small businesses can benefit from inventory segmentation. By categorizing inventory based on criteria such as sales velocity, value, and seasonality, small businesses can optimize their inventory management, reduce carrying costs, improve cash flow, and enhance their ability to respond to customer demands.

How does inventory segmentation impact customer satisfaction?

Inventory segmentation positively impacts customer satisfaction by ensuring that products are stocked appropriately according to their demand and sales patterns. This leads to better stock availability, quicker order fulfillment, and ultimately, faster delivery to customers.

What are some common mistakes to avoid in inventory segmentation?

Common mistakes in inventory segmentation often include neglecting data-driven methods for categorization. Additionally, failing to revise segmentation criteria and datasets regularly can lead to misalignment with consumer demands. Over-complicating the process or overlooking slow-moving items can also create inefficiencies and lead to excessive stock and higher holding costs.