In the world of business, managing inventory efficiently can make all the difference between success and struggle. Whether you’re a small startup or a large enterprise, optimizing your inventory is crucial for staying competitive and profitable. In this blog, we’ll explore some key inventory optimization strategies that can benefit businesses of all sizes and industries.

Top 5 Inventory Optimization Strategies Explained

Managing inventory efficiently is vital for any business. Here are five simple yet powerful strategies to optimize inventory and streamline operations:

1. Reduction of Minimum Order Quantity (MOQ):

- MOQ refers to the minimum quantity of a product that a supplier is willing to sell. By negotiating lower MOQs with suppliers, businesses can reduce the amount of inventory they need to purchase at once.

- This strategy helps prevent overstocking of products that may not sell quickly, freeing up capital and storage space for other items.

2. Vendor Managed Inventory (VMI):

- VMI is a collaborative approach where suppliers manage inventory levels for their customers. Suppliers monitor stock levels and replenish inventory automatically, based on agreed-upon criteria such as sales data or predefined inventory levels.

- VMI reduces the burden on businesses by outsourcing inventory management tasks to suppliers, ensuring timely replenishment and minimizing stockouts.

3. Frame Contract for Runner Items:

- Runner items are products that are consistently in high demand. Establishing a frame contract with suppliers for these items ensures a stable and predictable supply.

- Frame contracts outline terms such as pricing, delivery schedules, and minimum order quantities, providing both parties with clarity and consistency in transactions.

4. Lead Time Reduction:

- Lead time refers to the time it takes for an order to be fulfilled from the moment it is placed. By working closely with suppliers to shorten lead times, businesses can minimize the time inventory sits idle in warehouses.

- Strategies for lead time reduction may include optimizing transportation routes, improving communication with suppliers, and investing in technologies that expedite order processing.

Read more on Optimizing Inventory and Lead Time Management on our website SCMDOJO!

5. Pareto Approach: Top 50 Value Items:

- The Pareto Principle, also known as the 80/20 rule, states that roughly 80% of effects come from 20% of causes. Applied to inventory management, this principle suggests that a small percentage of items typically account for the majority of sales or value.

- By focusing on the top 50 value items, businesses can prioritize their efforts and resources on managing the most significant contributors to revenue and profitability.

In conclusion, implementing these five inventory optimization strategies can help businesses improve efficiency, reduce costs, and enhance customer satisfaction. By leveraging simple yet effective approaches, businesses can achieve better control over their inventory and drive sustainable growth.

If you want to learn more about Inventory Reduction Strategies please see our blog

18 Targeted Inventory Reduction Strategies for Supply Chain Professionals

Additional Points:

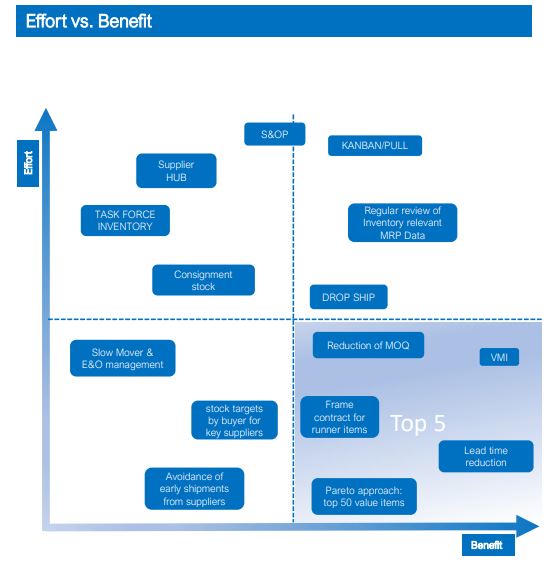

Value Benefit Analysis and Easy Implementation:

Inventory optimization begins with understanding the value of each strategy. By conducting a value-benefit analysis using a points-based system, businesses can prioritize strategies based on their potential benefits and ease of implementation. The goal is to identify strategies that offer significant benefits while being easy to implement, ensuring quick and measurable success.

P-D-C-A Method for Inventory Optimization:

The P-D-C-A method (Plan-Do-Check-Act) serves as a roadmap for effective inventory optimization initiatives. It involves planning the strategy, implementing it, checking the results, and acting on any necessary adjustments. This iterative approach allows businesses to continuously improve their inventory management processes, leading to measurable success over time.

Importance of Teamwork and Collaboration in Inventory Optimization:

Successful inventory optimization requires collaboration across departments, particularly involving purchasing and IT. These departments play critical roles in implementing and maintaining inventory optimization strategies. By fostering teamwork and collaboration, businesses can streamline processes, resolve challenges more effectively, and achieve faster results.

Additional Strategies for Consideration:

While the top 5 strategies provide a solid foundation for inventory optimization, businesses should also explore other potential strategies tailored to their specific needs. Strategies such as avoidance of early shipments, drop shipping, and setting stock targets for key suppliers can further enhance efficiency and profitability. However, weighing the pros and cons of each strategy and considering their suitability for your business context is essential.

Read more on 10 Inventory Control Techniques That Are Evergreen on our website SCMDOJO!

Case Study or Practical Example:

Let’s look at a real-world example to illustrate the effectiveness of inventory optimization strategies. Company X, a medium-sized retailer, implemented a combination of the top 5 strategies discussed in this blog. By optimizing their inventory management processes, they were able to reduce lead times, minimize safety stocks, and improve overall efficiency. As a result, Company X experienced significant cost savings and increased customer satisfaction.

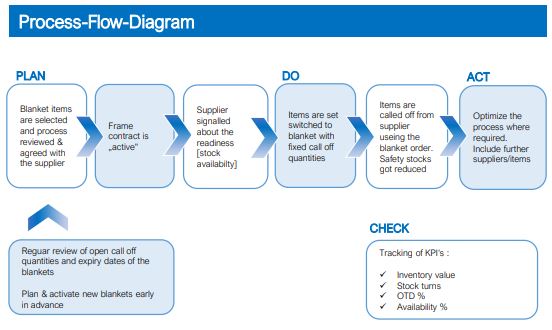

Process Flow Diagram:

Managing inventory effectively requires a clear and structured process. A process flow diagram outlines the steps involved in optimizing inventory through regular review and proactive planning. Let’s break down each step:

Regular Review of Open Call-Off Quantities and Expiry Dates of the Blankets:

Regularly reviewing open call-off quantities and expiry dates of blanket orders ensures that inventory levels remain aligned with demand. This step helps prevent overstocking or stockouts, allowing businesses to optimize inventory levels effectively.

Plan & Activate New Blankets Early in Advance:

Planning and activating new blanket orders well in advance is essential for maintaining a seamless supply chain. Here’s how the process unfolds:

- Plan: Select blanket items and review processes with suppliers to ensure clarity and alignment.

- Activate: Initiate a frame contract with the supplier.

- Notify: Inform the supplier about the readiness and availability of stock.

Do:

Executing the plan involves transitioning items to blanket orders with fixed call-off quantities and calling off items from the supplier using the blanket order. This helps in reducing safety stocks and streamlining inventory management processes.

- Set items to blanket orders with fixed call-off quantities.

- Call off items from the supplier using the blanket order, resulting in reduced safety stocks.

Act:

Continuous improvement is key to optimizing inventory management processes. After implementation, it’s essential to evaluate and optimize the process as needed.

- Optimize the process where required based on feedback and performance.

Check:

Tracking key performance indicators (KPIs) is crucial for assessing the effectiveness of inventory management strategies. Key metrics to monitor include:

- Inventory Value: Measure the total value of inventory to ensure optimal investment.

- Stock Turns: Evaluate how quickly inventory is sold or used within a given period.

- On-Time Delivery (OTD) Percentage: Assess the percentage of orders delivered on time to customers.

- Availability Percentage: Measure the percentage of time products are available for customers to purchase.

By regularly reviewing and optimizing inventory management processes using this structured approach, businesses can enhance efficiency, reduce costs, and improve customer satisfaction.

Pros and Cons of Implementing Blanket Orders

Implementing blanket orders can offer several advantages for inventory management, but it also comes with its own set of challenges. Let’s explore the pros and cons:

Pros:

Reduced Lead Time:

Implementing blanket orders can significantly reduce lead times, allowing for faster procurement and delivery of goods.

Impact on Safety Stocks and Re-order Levels:

With reduced lead times, businesses can maintain lower safety stock levels and optimize re-order levels, leading to cost savings and improved efficiency.

Inventory Value Reduction:

By selecting the right items for blanket orders, businesses can reduce inventory value by 30-40%, freeing up capital for other investments.

Supplier Risk Mitigation:

Implementing a frame contract provides suppliers with stability and predictability, allowing them to plan their supply chain more effectively.

Purchase Commitment:

Blanket orders provide an additional safety net for suppliers through purchase commitments, ensuring a steady stream of orders over the contract period.

Cons:

Time-Consuming Preparation:

The process of preparing and negotiating a frame contract for blanket orders can be time-consuming, requiring careful attention to detail and negotiation with suppliers.

Automated Call Off Process:

To effectively manage blanket orders, businesses need to automate the call-off process, often through ERP systems. This requires investment in technology and may entail additional implementation time and resources.

Manual Review of Blankets:

Despite automation, blankets need to be manually reviewed for open quantities, changes in demand, and expiry dates. This manual process can be time-consuming and prone to errors if not managed properly.

In conclusion, implementing blanket orders can offer significant benefits in terms of lead time reduction, cost savings, and supplier risk mitigation. However, businesses need to carefully consider and address the associated challenges to ensure successful implementation and ongoing management of blanket orders.

Conclusion

In conclusion, inventory optimization is a continuous journey that requires careful planning, collaboration, and the implementation of effective strategies. By prioritizing value, leveraging the P-D-C-A method, and fostering teamwork, businesses can streamline their inventory management processes and achieve sustainable success. Remember, the key to success lies in taking action and continuously refining your approach to meet evolving business needs.

So, are you ready to optimize your inventory and unlock new levels of efficiency? Start implementing these strategies today and watch your business thrive!

About the Author – Roberto Köster

Roberto Köster, with over 15 years of experience in supply chain management, logistics, and warehousing within the manufacturing industry. His expertise includes inventory analysis and optimization, problem-solving through LEAN principles, improving delivery performance, and enhancing customer experience.

In his journey of inventory optimization, he has encountered various methods, some complex and others simpler yet equally effective. While complex projects require collaboration across departments and extensive testing, he has found that simple methods often yield significant benefits. Despite challenges like changes in purchasing processes, the focus remains on delivering measurable results swiftly.

Based in Germany, feel free to reach out via email or LinkedIn for further discussions.

Email: [email protected]