Wave planning, waveless fulfilment, and order streaming: an overview

Wave planning and simultaneous use of waveless technologies can have an immense impact on your efficiency, productivity, profitability, and customer service levels. The omnichannel environment puts pressure on your distribution, supply, and fulfilment processes, so a quick and flexible process is a must.

Using order streaming, you can flexibly switch between wave planning and waveless fulfilment where they’re required, with excellent results.

We look at the functions of wave planning, waveless fulfilment, and order streaming, along with the requirements, processes, and benefits of order streaming on your fulfilment strategy, starting with this video from Manhattan Associates:

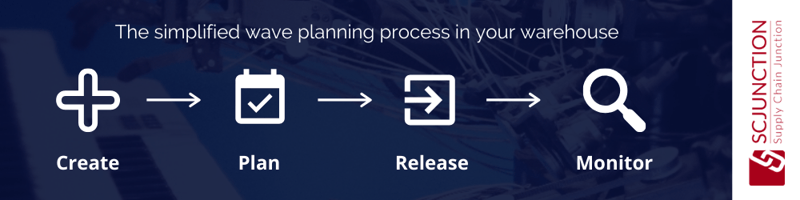

The basic functions of wave planning in your WMS:

Your wave planning tool should allow you to manage the process of order identification and selection, inventory assessment and allocation, labour scheduling, picking task allocation and monitoring of your fulfilment process, as outlined in the graphic above.

Planning ahead is critical, especially in high-turnover warehouses, and wave-planning gives you the tools to manage these influxes of demand efficiently and productively.

In the event that a pre-planned wave does not cover the requirement for fulfilment, your warehouse can switch to waveless fulfilment to cover your bases:

Using waveless fulfilment, batch picking, or order streaming in your warehouse

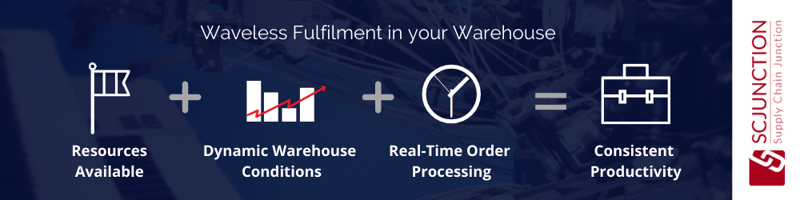

To nail waveless fulfilment, you need to approach your systems automation from a holistic angle. Waveless fulfilment gives you the flexibility to pull orders from a constantly updating, dynamic pool of available orders and opportunities.

While your wave-planning may account for planned periods of productivity, your waveless planning allows you to fill the gaps with opportunistic picking to ensure that your labour is optimised, MHE is used efficiently, and that order turnover is working at optimum at all times.

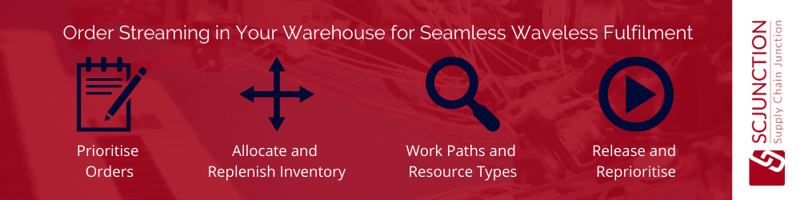

How order streaming technology can boost your waveless fulfilment

Using cutting-edge optimisation engines and prediction models, the order streaming function learns the patterns, flows, and changes within your warehouse to evaluate and adjust to your warehouse asset availability.

The benefits of using simultaneous fulfilment strategies:

Using a WMS that gives you flexibility to switch between wave and waveless functionality on demand gives you a firmer hold of your omnichannel fulfilment requirements.

- The rise of omnichannel has made order streaming a requirement, and ensuring that you can efficiently cater to orders from all corners of the omnichannel experience without dropping the ball is critical. Wave planning gives your business a hold on the repetitive, large-scale operations, while order streaming delivers on the faster turnaround, short lead-times that are prevalent in online and app-based orders.

- Order streaming can facilitate shipments to smaller retailers or outlets that have a varying demand, while your wave-planning facility manages the reliably high-demand deliveries.

- Order streaming allows a speedy order delivery for perishables, pharmaceuticals, and the like.

- In any situation where shipping cannot be done proactively, with orders pre-empted and estimated ahead of time, order streaming lets you pick up the slack and ensure delivery continues uninterrupted.

With the rise of omnichannel shopping, the need for agile, time-sensitive fulfilment will grow. A WMS with Order Streaming capabilities will ensure you are well-heeled to handle the demand from multiple areas, in varying demand cycles and quantities.

See how an efficient and well-implemented WMS with its extensive and comprehensive wave planning function helped Cambridge Foods to increase their warehouse productivity by 250%

TAGS

- WMS (51)

- Warehouse Best Practice (46)

- Implementing a WMS (29)

- Managing your warehouse (19)

- Omni Channel (18)

- eCommerce (18)

- Blog (16)

- Supply Chain Best Practice (16)

- Mid-Level (8)

- Customer Journey (7)

- Warehouse optimisation (7)

- General Tips (5)

- Industry General (5)

- Information (5)

- managing your Supply Chain (5)

- saudi arabia (5)

- Trends (4)

- smart warehouse (4)

- 3PL (3)

- News (3)

- ERP (2)

- Entry-level (2)

- ROI (2)

- Case Study (1)

- OMS (1)

- Picking (1)

- Press Release (1)

- Solution-Specific (1)

- Transport Management System (1)

Take A Look At The Results Of A Successful WMS Implementation.

See how Tarsus Distribution, in collaboration with SCJ boost overall efficiency by 60%