From the moment a customer requests a quote to the final product delivery, a complex web of processes is in play. Managing these processes requires meticulous tracking from quote-to-cash (QTC).

What is Quote-to-Cash?

The quote-to-cash process encompasses every step, from the initial request for a quote to the receipt of payment for the delivered product or service. It involves multiple departments, systems, and stakeholders, each playing a crucial role in ensuring a seamless flow of operations.

Quote-to-Cash Steps

1. Quoting

- The process begins with a customer inquiry or request for a quote.

- Sales representatives or an automated system generates quotes based on product specifications, pricing, and terms.

- Accuracy and timeliness are essential to provide customers with competitive quotes to secure business opportunities.

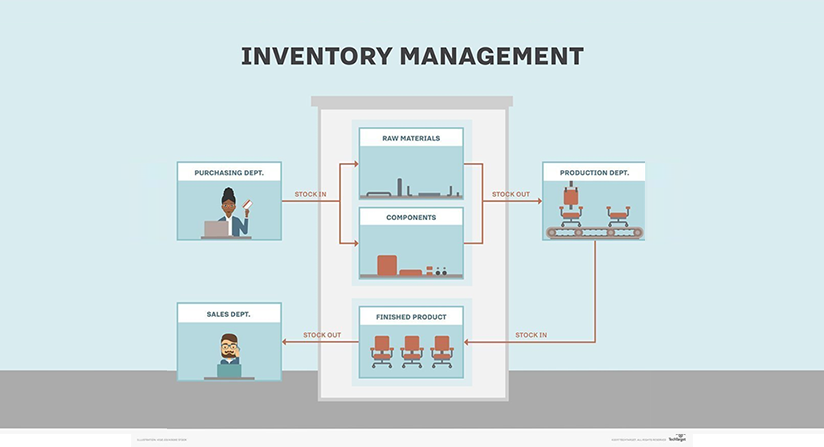

2. Order Management

- Once a quote is accepted, it transitions into an order.

- Order management involves creating, processing, and tracking orders, ensuring they align with customer expectations and organizational capabilities.

- Integration with inventory management systems is crucial to accurately confirm product availability and delivery timelines.

3. Production Planning

- Upon receiving an order, production planning kicks in.

- This stage involves scheduling resources, allocating the workforce, and coordinating tasks to fulfill the order efficiently.

- Collaboration between production, procurement, and logistics teams is essential to optimize resource utilization and minimize lead times.

4. Manufacturing and Assembly

- The heart of the process lies in manufacturing and assembly.

- Skilled labor, equipment, and materials transform raw inputs into finished products.

- Quality control measures are integrated at various checkpoints to ensure compliance with specifications and standards.

5. Quality Assurance

- Quality assurance ensures that products meet predefined quality criteria.

- Testing, inspection, and validation processes are implemented to identify and rectify any defects or deviations.

- Continuous improvement initiatives help enhance product quality and customer satisfaction.

6. Shipping and Logistics

- Once products pass quality checks, they are prepared for shipping.

- Efficient logistics management is crucial to coordinate transportation, track shipments, and manage delivery schedules.

- Integration with shipping carriers and real-time tracking systems enables transparency and accountability throughout the supply chain.

7. Invoicing and Payment

- The final step in the QTC process involves invoicing the customer and receiving payment.

- Accurate invoicing ensures customers are correctly billed for the products or services rendered.

- Timely payment processing improves cash flow and financial stability.

Implementing Best Practices for Effective Tracking

Businesses should adopt best practices that enhance efficiency, accuracy, and customer satisfaction to ensure seamless tracking of the quote-to-cash process. Below are some best practices to follow.

1. Standardize Processes

- Establish standardized workflows and procedures across departments to minimize errors and inconsistencies.

- Document processes and provide training to employees to ensure compliance and proficiency.

2. Foster Collaboration

- Encourage collaboration between sales, production, finance, and logistics teams to align objectives and resolve issues proactively.

- Implement cross-functional meetings and communication channels to facilitate information sharing and decision-making.

3. Embrace Automation

- Automate repetitive tasks and manual processes wherever possible to reduce cycle times and improve accuracy.

- Leverage robotic process automation (RPA) and machine learning algorithms to enhance efficiency and scalability.

4. Monitor Key Performance Indicators (KPIs)

- Define and monitor quote-to-cash cycle times, order accuracy, production yields, and customer satisfaction KPIs.

- Use dashboard reporting and analytics tools to track performance metrics in real-time and identify areas for improvement.

5. Continuously Improve

- Foster a culture of continuous improvement by soliciting feedback from employees, customers, and stakeholders.

- Implement regular reviews and retrospectives to identify bottlenecks, implement corrective actions, and drive innovation.

Image source : McKinsey & Company

Technology for Tracking

Tracking the Q2C process requires robust functionality. A manufacturing Enterprise Resource Planning (ERP) system can allow manufacturers to track the complete quote-to-cash process. It integrates core business functions, including order management, production planning, inventory control, and financial management, enabling seamless coordination across departments.

Manufacturing ERP includes a CRM system that centralizes customer data, interactions, and transactions, providing sales teams with insights to personalize quotes and manage customer relationships effectively.

Manufacturing ERP also has a Manufacturing Execution System that provides real-time visibility into manufacturing operations, tracking production progress, resource utilization, and quality metrics to optimize efficiency and productivity.

Its Supply Chain Management software optimizes supply chain processes, from procurement to distribution, by streamlining supplier relationships, inventory management, and logistics operations.

The Business Intelligence tools in manufacturing ERP analyze data from various sources to generate actionable insights, enabling businesses to identify trends, forecast demand, and optimize pricing strategies.

OptiProERP with SAP Business One Tracks All Steps from Quote to Cash

OptiProERP with SAP Business One is a manufacturing ERP that tracks all of the steps in the Q2C process. Its robust business and manufacturing functionality connects the entire organization from end to end.

C&C Manufacturing, makers of the Al-jon equipment that crushes cars to recycle steel and aluminum and high-speed airport snow removal machines, was looking for a system to track from Quote to Cash. After an extensive evaluation, they chose OptiProERP over ten other ERP vendors. See below what their president said about what made them select OptiProERP with SAP Business One.

– David Bradford, President, C&C Manufacturing

For more information about OptiProERP with SAP Business One, Watch Product Tour

Conclusion

Mastering the quote-to-cash process is essential for businesses striving to deliver customer value efficiently and profitably. Organizations can streamline operations, enhance visibility, and optimize performance across the entire value chain by implementing robust tracking, leveraging manufacturing ERP, and embracing best practices. In an increasingly competitive marketplace, effectively tracking from quote to cash is a strategic advantage and a prerequisite for sustainable growth and success.

Follow Us