Demand Planning: Whipped And Chained by Tradition

Supply Chain Shaman

SEPTEMBER 13, 2023

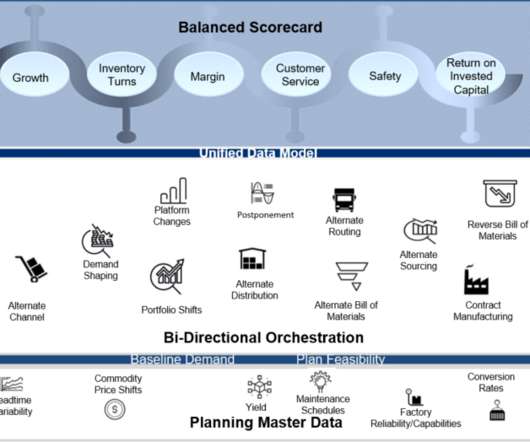

Given your expertise, I’d love to hear what alternatives you recommend for better demand forecasting and real-time visibility beyond what’s commonly adopted today.” The issues are largely rooted in politics and the lack of clarity on supply chain excellence. Or planned orders to purchase orders?) The reason?

Let's personalize your content