Will Trucking Challenges Transform JITS in North America?

QAD

OCTOBER 22, 2019

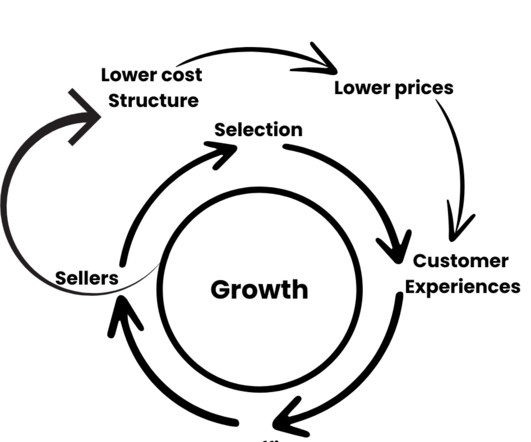

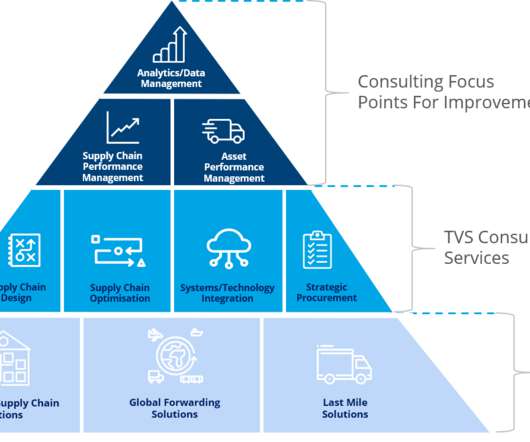

JITS is the acronym for “just-in-time-sequence,” a common supply chain practice in the automotive industry that eliminates or significantly reduces the need to maintain parts inventory at the assembly plant. Cost savings in warehousing and floor space along with associated reduction in personnel required. But why just in North America?

Let's personalize your content