How “Process Robots” are Enabling Supply Networks

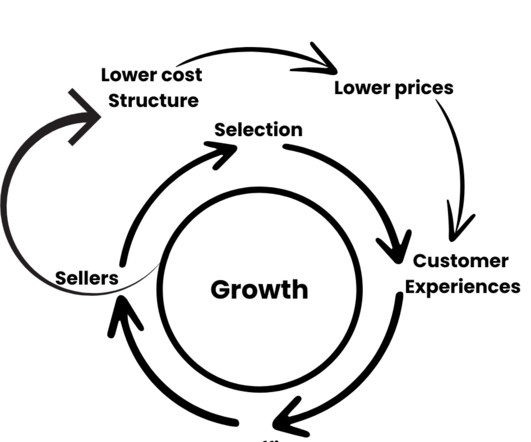

The Network Effect

JUNE 25, 2014

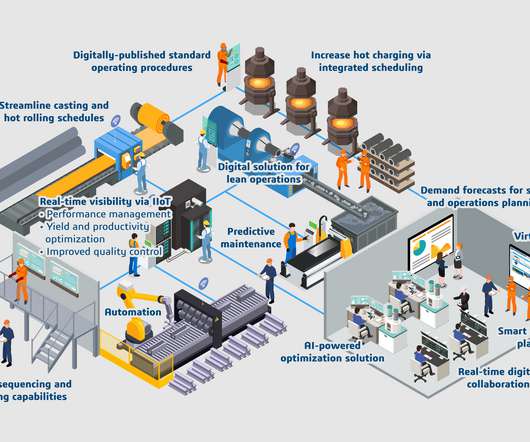

Think about an electronic workforce of process robots designed to count your inventory items in real time, on demand, with no mistakes made. Unfortunately the S&OP process wasn’t integrated well between business functions and a budget for this effort was never established. You pay them nothing, and they never complain.

Let's personalize your content