How to create a Bill of Materials (BOM) in product manufacturing

TradeGecko

NOVEMBER 8, 2018

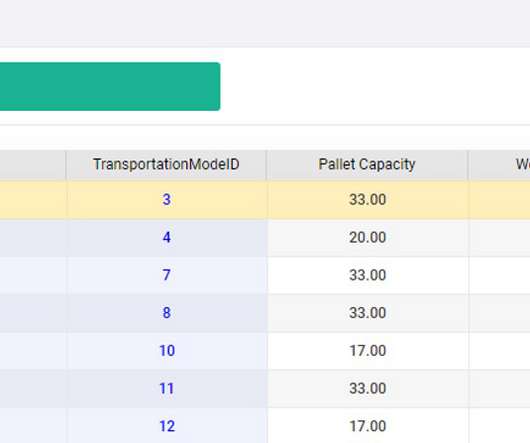

As we touched upon in the last article of our product manufacturing series , creating a Bill of Materials (BOM) is a critical step in the manufacturing process.

Let's personalize your content