2024: Planning for Success Amid the Uncertainty

Logistics Viewpoints

FEBRUARY 14, 2024

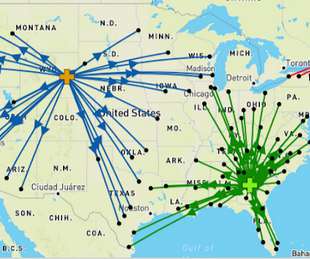

Five Year Performance on Business Goals (2019 – 2023) Looking at 2024 Priorities When it comes to organizational priorities across supply chain functions for 2024, APQC finds that supply chain planning remains in the top spot for the fifth year (selected by 90 percent of organizations).

Let's personalize your content