2024: Planning for Success Amid the Uncertainty

Logistics Viewpoints

FEBRUARY 14, 2024

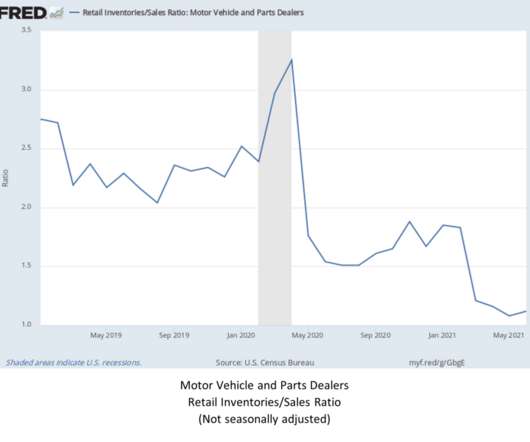

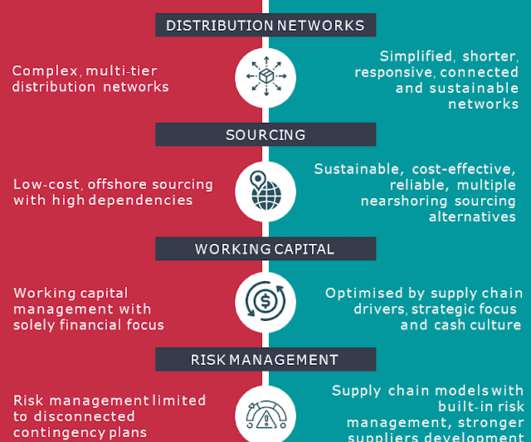

Fewer organizations achieved their business goals in 2023 than in any recent year, aside from 2020. Sourcing and procurement comes in close second at 88 percent, followed by innovation at 87 percent. Logistics and inventory management rounds out the top four focus areas at 82 percent.

Let's personalize your content