2020 Requires Big Wings and Feet

Supply Chain Shaman

OCTOBER 8, 2019

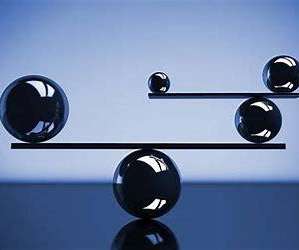

The fall ritual precedes the dropping of the ball on Times Square to ring in 2020. Financial forecasts tend to have a negative bias (forecasts less than market potential) to ensure that employees have a better probability of meeting their bonuses. 5 A Focus on Functional Metrics Throws the Supply Chain Out of Balance.

Let's personalize your content