This Week in Logistics News (May 20 – 26)

Logistics Viewpoints

MAY 26, 2023

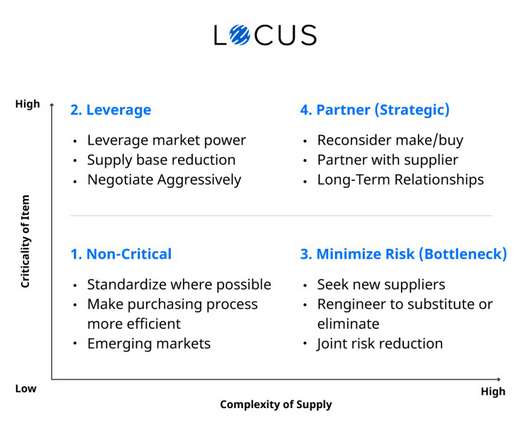

The trouble today is finding authentic pairs which also do not cost an arm and a leg. This resulted in meaningful cost savings for our last mile delivery program overall,” he added. Serota said that both sides are “spending a lot of time at the negotiating table, and I am optimistic we will hear good news soon”.

Let's personalize your content