Report-Apple iPhone India Based Production Upwards of $14 Billion

Supply Chain Matters

APRIL 10, 2024

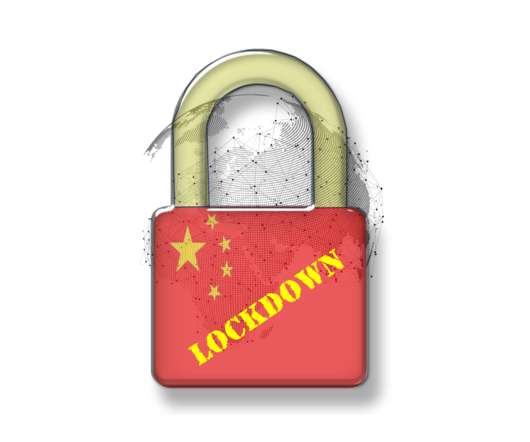

Supply Chain Matters calls reader attention to a report by Bloomberg indicating that upwards of 14 percent of Apple iPhone production, equating to $14 billion, is now being produced within India. Background Throughout 2022 and 2023, we have highlighted for readers the various indications of Apple’s unfolding China Plus sourcing moves.

Let's personalize your content