What is Just in Time Manufacturing? Benefits & Disadvantages

Unleashed

APRIL 18, 2024

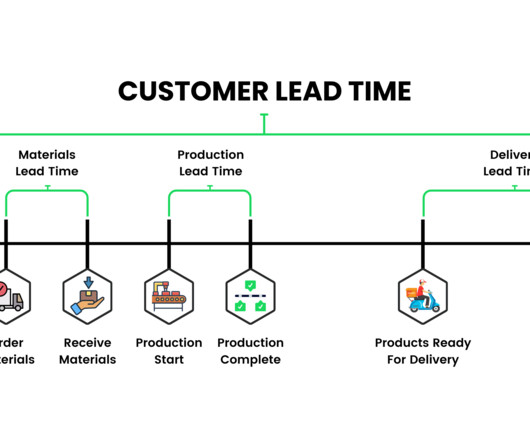

The manufacturing industry thrives on efficiency gains. Just-in-time (JIT) manufacturing is a production management approach that helps you lift efficiency and streamline your operational processes. What is just-in-time manufacturing? What is just-in-time manufacturing?

Let's personalize your content