The Green Corridor: Food for Thought

The Logistics & Supply Chain Management Society

SEPTEMBER 14, 2023

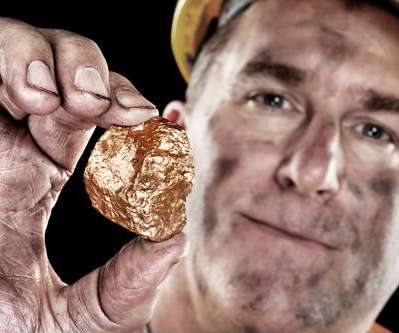

The term “Blood diamonds” was even created to highlight the harm that diamond mining was having in some West African countries. Test in-house when you receive their goods, or use an independent surveyor to test and certify quality independently? But these raw materials are only some of the most written about.

Let's personalize your content