How to achieve six-figure benefits from digitizing paper-based supply chain operations

By Sunil Koul

The traditional paper-based approach to supply chain operations presents serious challenges and perils. Digitization, in turn, offers a bounty of benefits – up to and including six-figure cost savings and significant efficiency and revenue gains. Here’s how.

Digitization is sweeping through the supply chain industry.

And it’s upending age-old practices.

Thirty-three percent of respondents to a 2016 Price-waterhouseCoopers (PwC) survey, Industry 4.0: Building the Digital Enterprise, declared they have a high level of digitization in their processes.

That number is expected to skyrocket to 72% by 2020.

But digitization can be easier to talk about than to implement. It is a concept that can be overly abstract and abstruse. When asked to describe the principle challenges that they face in digitization, nearly a third (27%) of supply chain respondents to a 2017 IDC survey replied, “What’s digital transformation?”

But digitization is not an abstraction. It’s a set of clear practices that yield tangible benefits.

In this paper, we’re going to focus on a specific aspect of digitization in the supply chain: taking paper out of your warehouse, supplier, and manufacturing workers’ hands and replacing it with a smart device. Why would we even consider this? Simple: doing so ad-dresses a multitude of challenges faced by today’s supply chain organizations:

- Dependency on enormous (and expensive) quantities of paper, printers, and ink;

- Even more dependency on the humans for handling the papers generated internally;

- Time for the clerk or worker to execute critical tasks, including picking, packing, move order, scanning, cycle counting, and so on;

- Inefficiency given that the traditional, paper-led pick path is less productive and more time-intensive;

- Delays in the customer delivery; and

- Errors when the wrong product is sent to the customer (which is commonplace in a typical eCommerce company that has millions of similar or related items on the shelf).

Take the paper out of your processes.

Paper permeates almost every aspect of your operation. A typical e-commerce company that does $200M to $500M likely spends around $500,000 to $1 million every year for the requisite infrastructure and resources, i.e. printers, papers, and ink. And don’t forget the costs associated with trashing these papers since they are discarded after use.

The most immediate tangible benefits are resource reduction, improved inventory accuracy, and less investment in infrastructure. The exact dollar amounts saved will depend on the company’s current spending on resources like printers, paper, ink; communication cost to employees; inventory; etc.

However, the cost savings and efficiency gains can be substantial. At Art.com – which receives around 10,000 to 15,000 orders per day for artwork, poster prints, and similar goods – we’ve saved $180,000 annually just for the paper. At the same time, we in-creased accuracy and customer satisfaction metrics.

It’s not just raw cost savings that can be achieved, either. For example, Zensar.com, a global technology services company that helps others with their own digital transformations, fully digitized its own internal operations. Digitizing their timesheet management system alone improved cash flow by almost 10%, Vineet Kumar, a Global Business Transformation Leader at Zensar, estimates.

PwC, in its 2017 study of digitization in the supply chain, found that “companies with highly digitized supply chains and operations can expect efficiency gains of 4.1% annually, while boosting revenue by 2.9% a year.”

How can supply chain organizations realize these kinds of gains for themselves, but without having to spend millions of dollars to do it? That’s the million-dollar question this paper will address.

What does it mean to digitize a paper-based workflow?

First, we need to understand supply chain execution and its traditional reliance on paper.

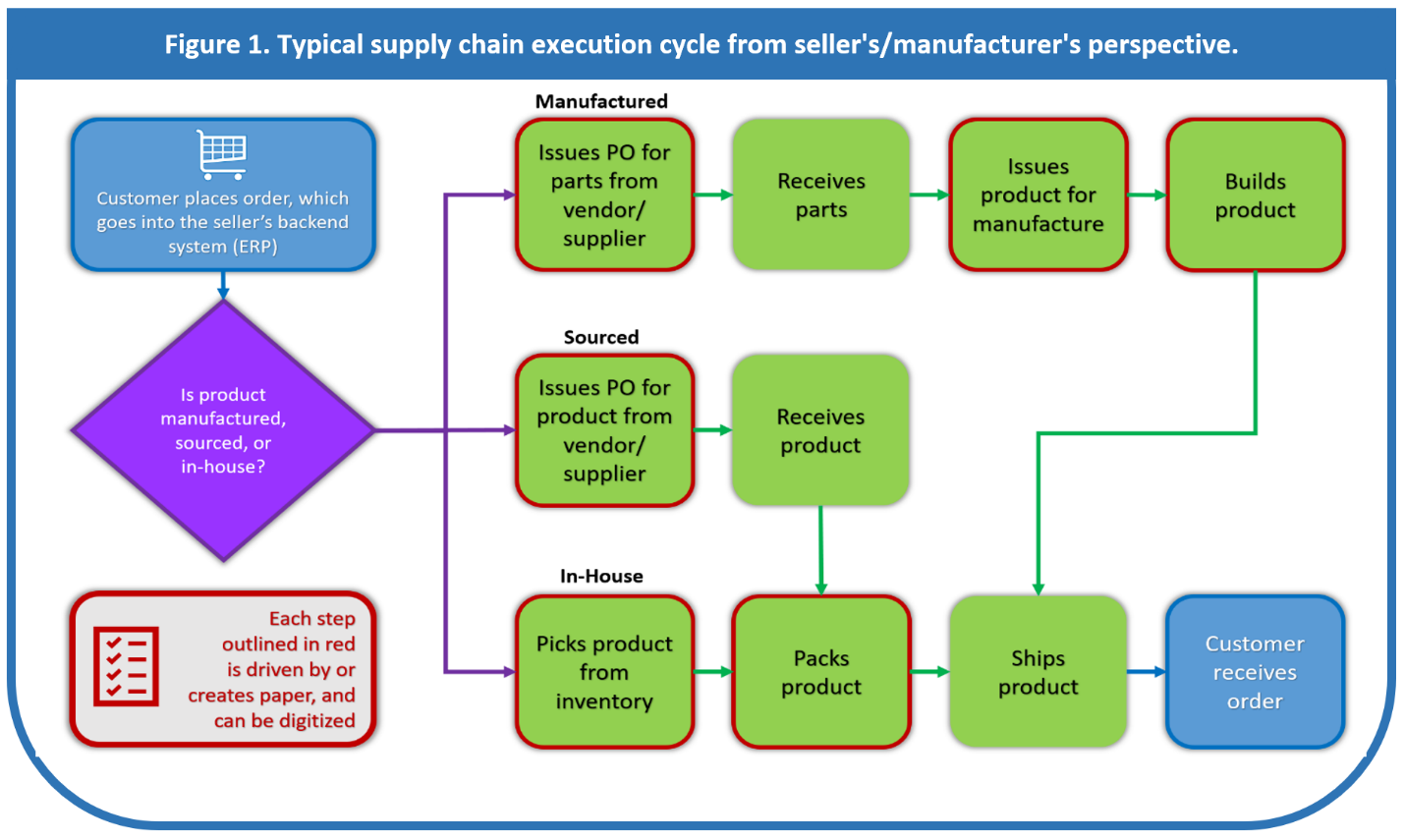

When describing the supply chain, we are talking about multiple sequential and parallel activities that are necessary to execute a typical supply chain cycle (see the illustration below). Almost every transaction – except, perhaps, receiving the customer order itself – is executed based on paperwork in most industries today. Whenever the order hits the floor, a lot of paperwork kicks off, as shown in the visual. Enterprise Resource Planning (ERP) software can help create a workflow that takes the organization from one operation to another, but it won’t help them to get rid of the paper so easily.

For example, for picking an item from the warehouse, a picker would need a paper pick slip to identify the product the customer ordered. So, someone must get a piece of paper that identifies the customer, the product, and the product’s location. The picker then runs to Shelf A, Bin 5 to grab the item – but first they need to make sure the item is right. Not only does the picker need a printed pick slip, they also need a color image of the product if they need to select between like items or similar SKUs, e.g. we have 100+ posters of Michael Jackson here, is the picker grabbing the exact right one? The accuracy of picking the right product depends on the paper and the picker’s judgment.

From there, they’ll put the item in the cart, take it to the packer, pack it, give it to the shipper, manifest it, give it to UPS/FedEx/USPS, etc. Altogether, we deal with 5 or 6 hops as we move through the supply chain, all of which are driven by printed paperwork. Then, most of these printer documents just get trashed because they are used only internally and are not necessarily sent to the customer.

All this remains particularly true of mid-size and small-size companies that cannot afford to invest billions of dollars (unlike, say, Amazon- or Apple-scale companies) into robotics and operational software. The good news is that they can still digitize their operations without investing much of their profit and can reap the benefit of the digitization.

How do you achieve this digital transformation? A 4-step process.

1: Break down the supply chain cycle at your organization.

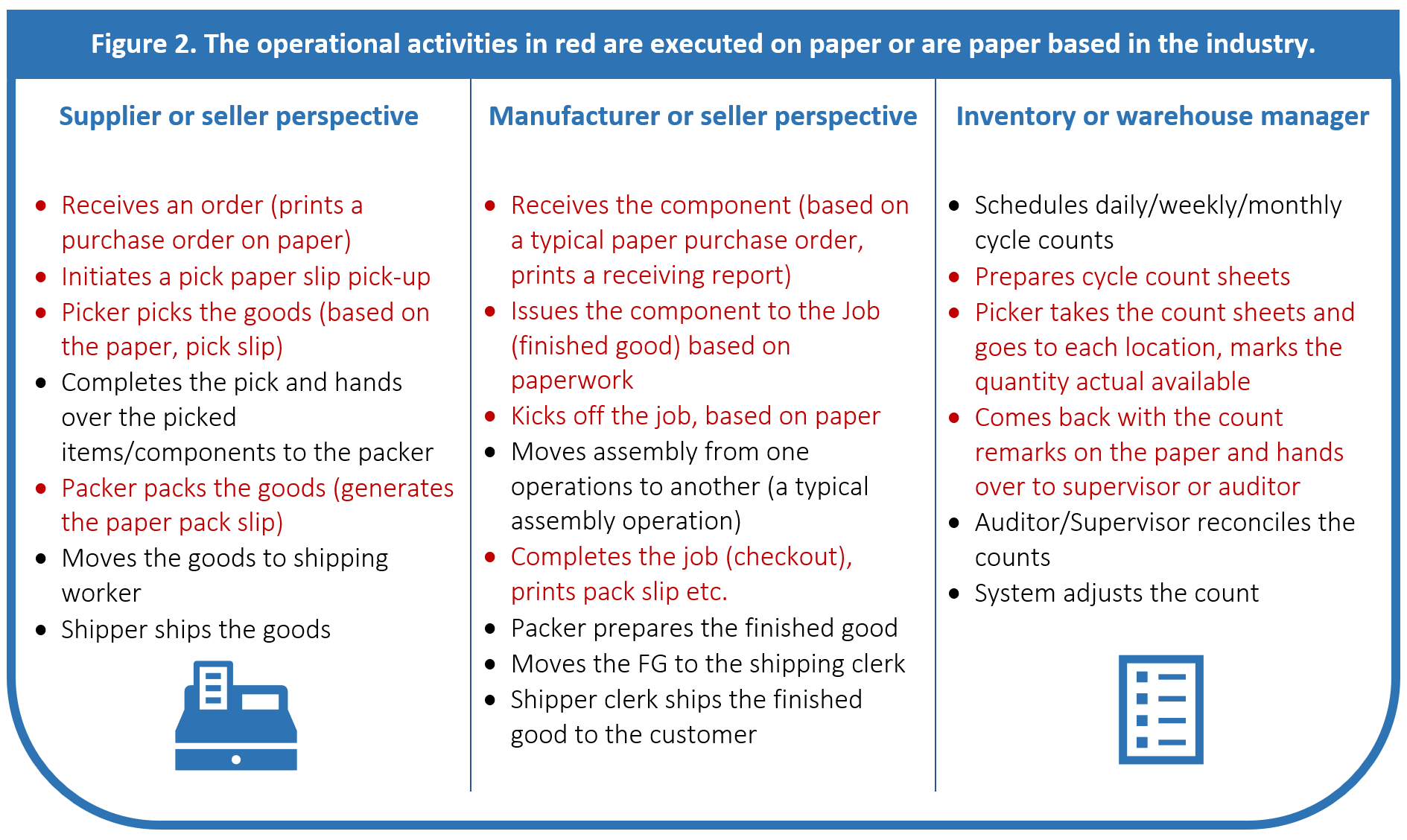

The first step toward digitizing requires the organization to break the whole operational cycle down into individual steps. The illustration on the previous page and the task breakdown in Figure 2 below both represent a good start on this step; in these figures, we have identified the discrete functions to be performed at each stage of a typical supply chain execution cycle.

Any complex workflow will have many different pieces and parts, and you must start by breaking the cycle down at a very high level into small, definable pieces. Once the discrete functions have been identified – such as receiving, picking, shipping, etc. and all their component workflows – we can start asking if and how we can undertake each step digitally or visually in lieu of paper.

2: Identify what steps in the process can – or cannot – be digitized.

In Figure 2, each bullet point represents a discrete function within the supply chain cycle. Some items are already digital (e.g. your ERP might adjust the inventory count automatically already), and others cannot be divorced from paper unless your partners have also gone digital (e.g. you might still have to print a ship-ping label). Even in these cases, however, it’s still worth considering if there are ways to streamline or minimize the use of paper in the workflow. For example, if you need to print a few necessary documents no matter what – say, a shipping label and manifest – you could easily create a workflow where your people print wirelessly from their tablet or smartphone to a stationary desktop. You can then identify other steps that could be entirely replaced by digital means (such as the red items in the table below).

As a general guideline, avoid changing the process flows themselves. Instead, focus on the ways in which workers undertake current processes. That way, you can minimize the learning curve and ease adoption. By replicating the exact process that everyone was doing with paper, it simplifies training them.

How might all this look in practice? First, you hand a tablet or other smart device to each department worker who is part of the supply chain execution. Via that device, each worker will be provided a queue that he/she needs to execute. The work, action, or operation that they must perform is now in digital form. No supervisor will need to direct the workers to perform their tasks based on the papers that have been print-ed; instead, the worker will have to look at the queue on the smart phone.

Then, if a picker needs to pick a product that is complicated in terms of its image, stock location, and color resolution, the smart device will provide him not only with location and quantity information, it will also provide a full-color, high-res image of the item to be picked. That image helps him or her to pick exactly the right product.

It also saves time. As the picker traverses through the order that is available on the smart phone, he/she also realizes the best pick path. An optimized pick path would occur when the picker doesn’t have to return to the same location while picking a product in a batch that belongs to multiple customer orders. The digital system can help with this by queuing orders appropriately and alerting the user. Optimizing pick path can yield substantial efficiency gains. According to a 2016 DC Operations survey, the average size for a single distribution center is 264,445 square feet – and many companies operate entire networks of DCs with an average total square footage of 539,000 square feet. That’s a lot of space that simply takes time for pickers to traverse.

Every pick that picker performs now is being recorded in the system automatically. Each scan in the production now is being recorded. This provides the online/live tracking and progress of each employee, picker, packer, and/or production worker to the supervisors without really moving from their desk. It also develops the automatic production performance matrix of the employees working. As a result, the depend-ency on the human to enter his/her in and out time during the actual working is eliminated.

3: The third step is to look at your ERP capabilities.

For the scenario described above to work, you need to get the right data displayed on that smartphone or tablet. That requires that you determine what APIs you can leverage. These APIs go through interfaces in order to update the source and destination systems, so that the tablet in the worker’s hands can communicate seamlessly with the primary systems driving operations.

As an example, Oracle ERP has extremely high capabilities of providing a lot of APIs that can help you to get the data displayed on tablets, as does SAP. In fact, get-ting data from their systems onto mobile platforms has been a major focus for such organizations. “A lot of our customers are running massive operations that have to deal with content in many shapes and forms,” Harald Nehring, vice president product marketing, middleware, at SAP told CIO Magazine. “We’ve been building tightly integrated solutions … that address a lot of scenarios.”

If your company has a home-grown system, that sys-tem might work as well: it might be a more effort to build or set up, but at the same time it could be simpler as well, depending the technology used.

4: The final step is to decide what tools to use and put them in place.

Once you understand what your ERP and internal systems can and cannot do, you can begin to map out an implementation strategy.

One option is to use a third-party tool that has a mo-bile platform already built with which you can integrate. At Art.com, we used DSI Global to handle the ERP integration to interface between our Oracle-based system and the iPads we distributed to workers.

You can also develop your own in-house mobile inter-faces to display the data if you have enough of a technology footprint in the company. For an e-commerce retailer like Art.com, creating a proprietary tool would simply have been cost- and time-prohibitive. Why re-invent the wheel?

That said, the product that interfaces between the mobile devices and the ERP should provide the ability to make internal adjustments over time, such as tweaking process flows, without having to rely on an outside partner exclusively./p>

Once these key decisions are made, test early and test often. Testing the systems will work out a lot of potential bugs. For example, performance response time is key: we didn't want to get efficient with a paperless environment only to face five- or ten-minute windows between transactions populating. Worse, you might face system downtime or a crash – you want to dis-cover and resolve such issues before they result in unplanned disruption to your business.

If this seems like too much all at once, remember that the process doesn’t have to be all or nothing.

Though some companies – like Zensar – have digitized their operations fully, others focus solely on key areas of value.

PwC itself specifically recommends starting with “small pilots with end-to-end scope … that showcase benefits.” Organizations can then segment rollout, starting with those supply chains – based on “key customers, key regions, or some other supply chain segmentation criterion” – where the benefit would be greatest.

Keith Kmetz, program vice president for imaging, printing and document solutions at IDC, told CIO Magazine that “many companies have implemented a “paperless light” concept. It means, almost all internal processes are entirely paperless, but external process-es still involve printing and scanning to integrate into a digital storage system.”

How do you measure the benefit of this digital transformation?

“If you have any outcome that is not measurable, there's no point,” says Kumar. “By digitizing, we give ourselves measurable outcomes.”

Ultimately, you should be able to compare virtually every operation and its performance to the previous year and see how it has transformed operations into the digital high-performing environment.

For example, you can measure:

- Inventory accuracy and cycle count;

- Resource consumption – what you used for the current year versus previous one;

- Picker /packer performance;

- Number of products that you scanned and manufactured this year vs. last year along with the time/resources it took;

- Customer feedback in terms of wrong product received or damages received;

- Delivery satisfaction/FIFO matrix; and

- Satisfaction index of your employees using the smart tablets etc.

At Art.com, we saw productivity improvements on the labor front, efficiencies gained from no longer forcing workers to stand around at the printers, significantly reduced expenses from paper and ink printing, and order accuracy improvements simply from papers never getting out of order or misplaced.

Analysis and advisory firm McKinsey estimates that digitizing supply chain operations reduces lost sales by 50%, administrative costs by at least 5% to 10%, and even inventory costs by 20% to 50%.

But perhaps the most important and measurable improvement is how digitization enables supply chain organizations to keep up with the ever-accelerating speed of business.

As technology consultancy Accenture writes in its 2017 Delivering at the Speed of Business report, “Speed is the currency of the future. By making their supply chains more responsive, proactive, predictive, real-time and scalable, leading companies can move quickly to take advantage of growth opportunities.”

Conclusion: It won’t happen overnight, but digitization is easier than you think.

There are not many companies out there who have completed a full digital transformation in their supply chain execution, but those companies that have done it partially have found nearly universal success in the move.

In fact, digitization is not only helpful in the Supply Chain Management but also can be implemented in any business function like HR, Marketing, Sales, CRM, and other non-SCM product as well. It has a solid ROI.

Zensar’s complete digital transformation for its internal working environment has yielded phenomenal results. Their transformation included in the communication between executives to employees, HR communication, performance appraisal, resource allocation etc.

Employees do not carry a diary or a PC/laptop but just a smart phone or a tablet for anything and everything, from performance appraisals through HR meetings, from all hands gatherings to meetings with managers.

Digital transformation is evolving, and companies should consider it based on number of factors, like type of business, volume or non-volume business, high value or low value transactional business, type of ERP they have and so on. In my experience, digital transformation will be inevitable at some point of time. Moving early into this is a great thought process.

As one of Art.com’s executive team members said after the transition to digital: “It's the gift that keeps giving – year after year.”

About the author

Sunil Koul

Director of Business Applications, Art.com

Sunil has over 19 years of domain and enterprise resource planning experience covering multiple business functions that include supply chain operations, distribution, manufacturing, engineering,inventory management, self-service applications, Cloud applications like Salesforce in several leading industry sectors. Sunil has delivered projects in many fortune 500 companies that include, Facebook, Cisco, Agilent, Verifone. In his current role at Art.com, Sunil works as the business application owner covering the complete footprint of enterprise applications, responsible for delivering the solution and ensuring every business stakeholder's requirements are met. As such, Sunil played a key role in digitizing the supply chain and warehouse management operations, while improving operational efficiencies and precision.

© 2017 Sunil Koul. All rights reserved.

Let's personalize your content