National Manufacturing Day 2024

Enterra Insights

OCTOBER 3, 2024

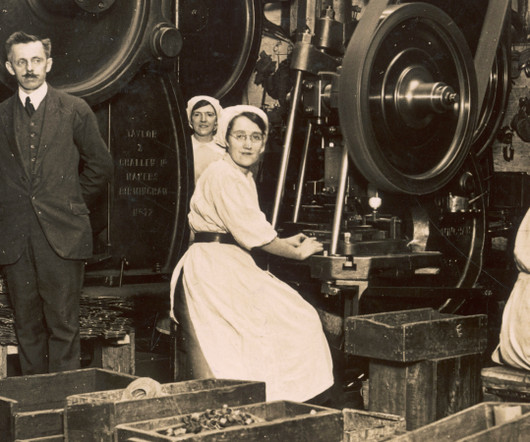

Tomorrow, 4 October, is National Manufacturing Day (MFG Day) — which is celebrated annually on the first Friday in October. The day is set aside to honor those who manufacture goods in the United States. manufacturing innovation, the growth potential of these jobs is high — more than 1.3 Driven by a renewed investment in U.S.

Let's personalize your content