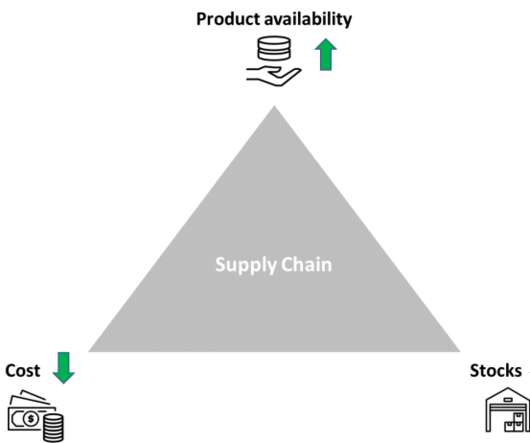

The worst Supply Chain practices must be confessed and not only by constraint

KEPLER Consulting

DECEMBER 11, 2019

The inability to provide daily updated data on inventories of raw materials, semi-finished products, and finished products presents two major concerns: The decrease of the WCR for companies, the deployment of a dashboard tailored and user-friendly is essential in order to take charge of the management of a share of its WCR. 46,2000, p.

Let's personalize your content