The Future of Supply Chains Post COVID-19 – LogiSYM July 2020

The Logistics & Supply Chain Management Society

JULY 22, 2020

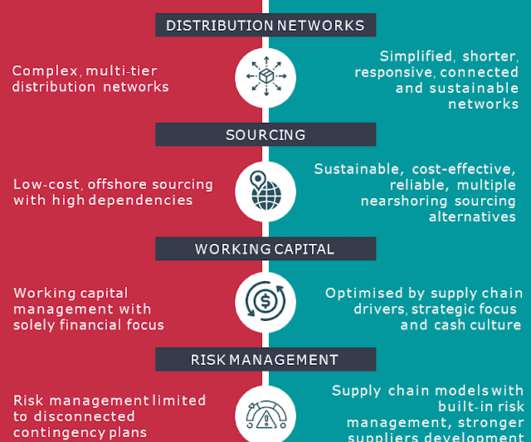

But companies will have to go beyond the usual inventory optimisation. . For example tools like self-billing can support to fasten time consuming transport invoices reconciliation etc…), several SC models will co-exist and will be intermediately used depending on the market condition. MORE FROM THIS EDITION.

Let's personalize your content