Interoperability in the Supply Chain: Leveraging the OSI Model for Seamless Logistics

Logistics Viewpoints

NOVEMBER 27, 2024

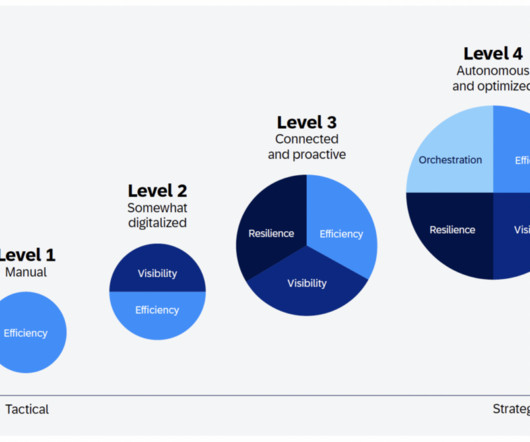

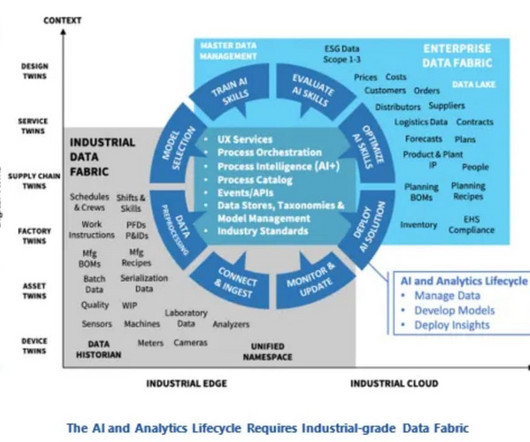

In the rapidly evolving world of global supply chains, interoperability—the ability of systems, devices, and organizations to work together seamlessly—has become a critical factor for operational efficiency. Here’s how each layer translates to the supply chain context: 1. Application Layer: Interfacing with end-user applications.

Let's personalize your content