Avoiding Dead-end Streets As We Build the Future of Supply Chain Planning

Supply Chain Shaman

SEPTEMBER 22, 2022

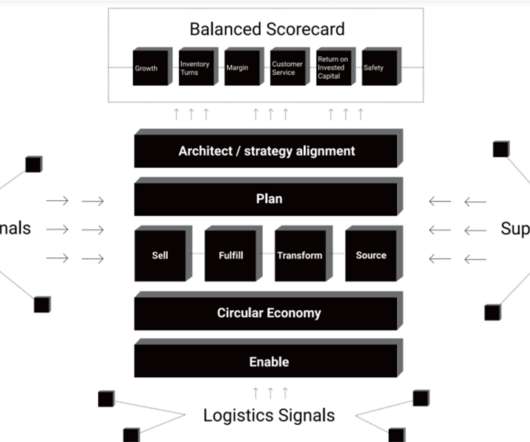

I am writing this post from a hotel room in Chicago. Seasoned supply chain professionals used the mental model from the recession of 2007 as a guidepost.) Planning taxonomies change to enable the trade-offs between source, make and deliver based on market signals and the design of supply chain flows to enable this shift.

Let's personalize your content