Pushing the Supply Chain Reset Button

Supply Chain Shaman

JUNE 29, 2022

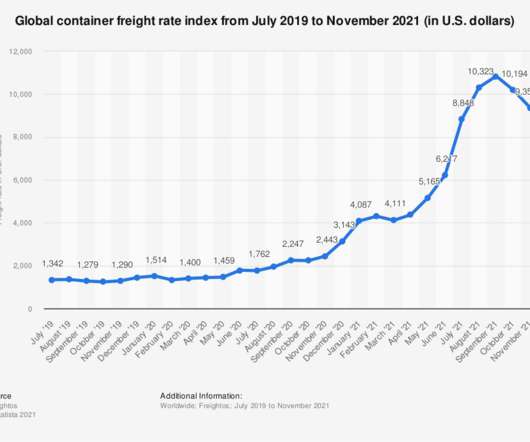

Concurrent macro forces–material shortages, war, shifts in consumer buying patterns, logistics constraints, inflation/recession, and climate change– are reshaping today’s reality necessitating the need for a supply chain reset button. In addition, the warehouses are full and containers are being used for overflow storage.

Let's personalize your content