The Future of Supply Chains Post COVID-19 – LogiSYM July 2020

The Logistics & Supply Chain Management Society

JULY 22, 2020

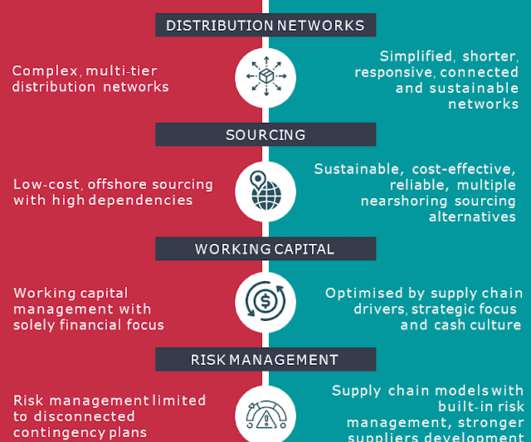

Such simulations would enable to assess the impact of a decrease/increase of demand, a capacity excursion in a factory or distribution centre. . Sourcing strategies will focus on risk-free, nearshoring supply base with long term partnership with TCO-competitive suppliers, who value sustainability. . MORE FROM THIS EDITION.

Let's personalize your content