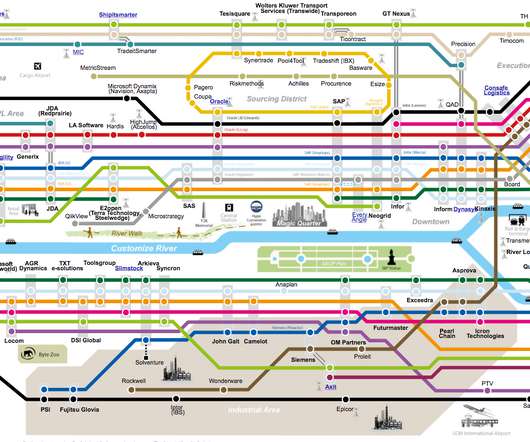

AIMMS Featured in IT Subway Map of European Supply Chain Software Providers

AIMMS

JUNE 26, 2017

This is the fourth time AIMMS is named in the IT Subway Map. ” AIMMS in the IT Subway Map. AIMMS can be applied in several areas of the supply chain. ” AIMMS is a Prescriptive Analytics technology. ” AIMMS is a Prescriptive Analytics technology. Mapping European Supply Chain Software.

Let's personalize your content