Top 20 Verified Supply Chain Experts You Can Hire

SCMDOJO

NOVEMBER 2, 2023

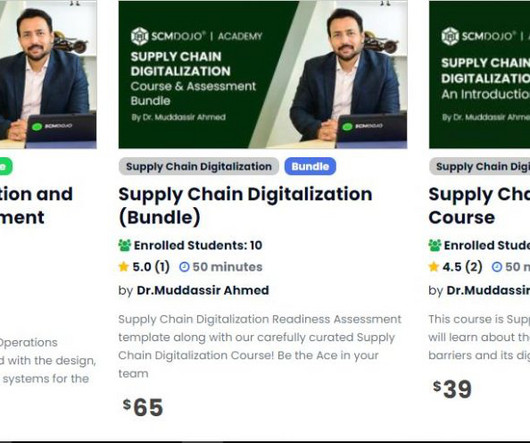

Services Matias Offer on SCMDOJO Logistics Consulting Maritime Freight Sourcing and Procurement Logistics Technology Sourcing Executive Mentoring Guide: Matias, our supply chain consultant, has also created Maritime Freight Sourcing and Procurement Guide , which is available from SCMDOJO Academy.

Let's personalize your content