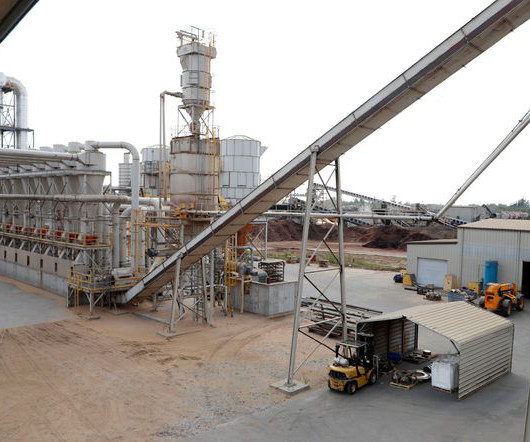

How manufacturers can enable innovation on the factory floor

SYSPRO Smarter ERP

SEPTEMBER 6, 2022

The past two and half years have certainly brought a variety of challenges and opportunities that have made innovation not just a preference, but essential for manufacturers and distributors to thrive into the future. Optimizing the use of data for manufacturers. The escalation of the war in Ukraine. A new phase of the pandemic.

Let's personalize your content