The Future of Supply Chains Post COVID-19 – LogiSYM July 2020

The Logistics & Supply Chain Management Society

JULY 22, 2020

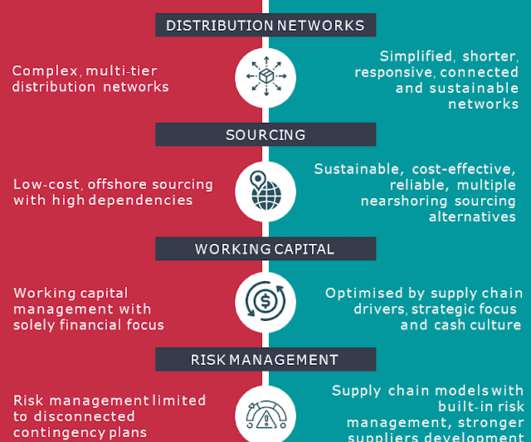

All eyes are on Asia again as it stands at the forefront of the next challenge for Supply Chains – to accelerate into recovery and rebound stronger, most likely in different ways. In this regard, B2G Consulting, has shared their thoughts on how the future of supply chain will look like post COVID. .

Let's personalize your content